LK Mechanik puts new main plant into operation

LK Mechanik + Blechverarbeitung GmbH recently put its newly built factory at the Hüttenberg-Rechtenbach site into operation. Here, the company now develops and manufactures innovative components and assemblies made of steel, stainless steel and aluminum on more than 4,100 square meters.

What LK Mechanik has built at its new headquarters in Hüttenberg-Rechtenbach, Hesse, is probably one of the most modern sheet metal processing plants currently to be found in the German SME sector. Plenty of open space for flexible organization of the production lines, machinery rich in high-tech systems, interior architecture that is as functional as it is elegant, and energy and building technology that is consistently trimmed for sustainability: "This is how factories work today," says company boss Tomas Loh, for whom the recent commissioning of the new site represents the preliminary culmination of a development that was set in motion in 2017. It was just under five years ago that he and his former company Loka took over LK Mechanik GmbH, which was located in neighboring Heuchelheim. Shortly thereafter, the decision was made at the beginning of 2019 to merge the two companies both legally and in terms of production - and to do so in a new plant in Hüttenberg-Rechtenbach. With the realization of this project, the innovative forces of two extremely successful players in German sheet metal and metal processing have now been combined in a company with 50 employees. "Our customers benefit in many ways from the resulting synergies," emphasizes Tomas Loh, and explains: "It is not only development and production competencies, technological equipment and employee qualifications that complement each other perfectly. We have also created an environment for all of this that corresponds to the latest findings in factory organization, process optimization, digitalization and ergonomics. It is already apparent that we can implement high standards of product quality and availability on this basis."

Development and series production

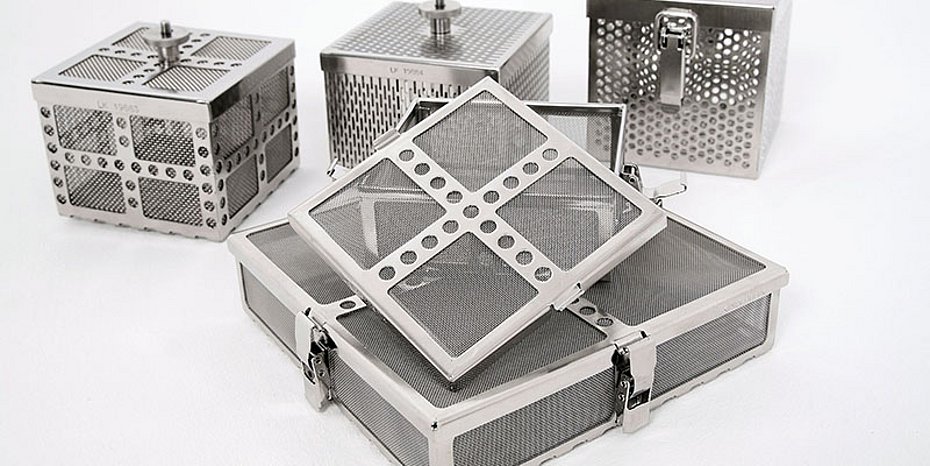

In its new plant, LK Mechanik + Blechverarbeitung realizes ready-to-use components and assemblies made of stainless steel, steel and aluminum for demanding customers in numerous key sectors of industry. At present, these are primarily plant and machine builders in packaging technology, the optical industry and assembly automation, as well as industrial parts cleaning, electronics and medical technology. In this context, the company's range of services extends from consulting and design to one-off and series production. "Other specialties include the development and manufacture of process-oriented washing basket systems and workpiece carriers for use in automated parts cleaning and assembly technology, as well as hygiene-relevant cleaning and sterilization trays for medical technology," reports Tomas Loh.

Partner for high demands

While LK Mechanik uses modern 3D CAD and prototyping systems in development, the focus of production is on CNC metal and sheet metal processing, fine cutting with laser and waterjet, punching and laser processing, as well as automated laser and robot welding and various surface engineering processes. Quality assurance is carried out using 3D coordinate measuring systems. The result is always ready-to-install components, assemblies and products that meet high quality standards - such as those for technical cleanliness, cleanroom technology, the semiconductor industry or sterilization technology. "Our quality management is certified according to DIN EN ISO 9001:2015, our process and procedure steps are stored in our ERP system in a way that can be documented and reproduced, and we are familiar with the requirements of numerous high-tech industries," says Tomas Loh.

Sustainability is a top priority

At the same time as commissioning its new plant in Hüttenberg-Rechtenbach, LK Mechanik has definedCO2 neutrality as one of the company's goals. The foundations for this have already been laid: A 350 kWp photovoltaic system operates on the roof of the new factory, the process heat generated in production is recycled, and the production lines operate under the guideline of consistentCO2 reduction. "We attach great importance to resource conservation and mindfulness of the environment, which is demonstrated, among other things, by our orchard, plans for employee gardens, a chicken mobile and tree projects for our customers. In addition - and this will become increasingly important in the future - we actively support our customers in plant engineering and their users in their efforts to conserve resources and protect the climate by implementing material-reduced, process-optimized and lighter designs," emphasizes Tomas Loh. (OM-04/23)

Contact

LK Mechanik + Blechverarbeitung GmbH

Budenweisgraben 9

35625 Hüttenberg-Rechtenbach (Germany)

Phone +49 (0) 6 4441 444666-0

E-mail: vertrieb@lk-mechanik.de

www.lk-mechanik.de

LK Mechanics

LK Mechanik GmbH was founded in 1978 and taken over by LoKa Metallverarbeitung GmbH in 2017. Both companies merged legally and spatially into LK Mechanik und Blechbearbeitung GmbH in 2022. Among other things, as a manufacturer of workpiece carrier systems, workpiece cleaning baskets and transport protection systems for manufacturing and cleaning technology, LK Mechanik covers a wide range of products. The company's customers include well-known users and machine builders in cleaning and surface technology, vehicle construction, subcontracting, process engineering, optics, metrology and numerous other industries.