Panacol presents new optical adhesives and materials

Panacol will present new optical resins for imprint and optical bonding applications at the SPIE Photonics West trade show in San Francisco, CA, USA, from January 28 to 30, 2025.

Panacol's new adhesives are typically used for light carpets in the automotive industry, for sensors in wearables or to generate structured light in projectors or time-of-flight sensor applications for automotive and consumer products. Panacol specializes in the formulation of resins for the replication of refractive lenses and diffractive optical elements (DOEs). These materials are well suited for micro- and nano-imprint lithography or wafer-level optics. These materials are not only suitable for the commonly used glass wafers, but the new generation of materials also exhibits exceptional adhesion to novel polymer substrates such as optical PET, PC or COP. After application and imprinting, these materials cure quickly under UV light and form a precise and durable structure. The optical properties are specially tailored to the requirements of the target substrate.

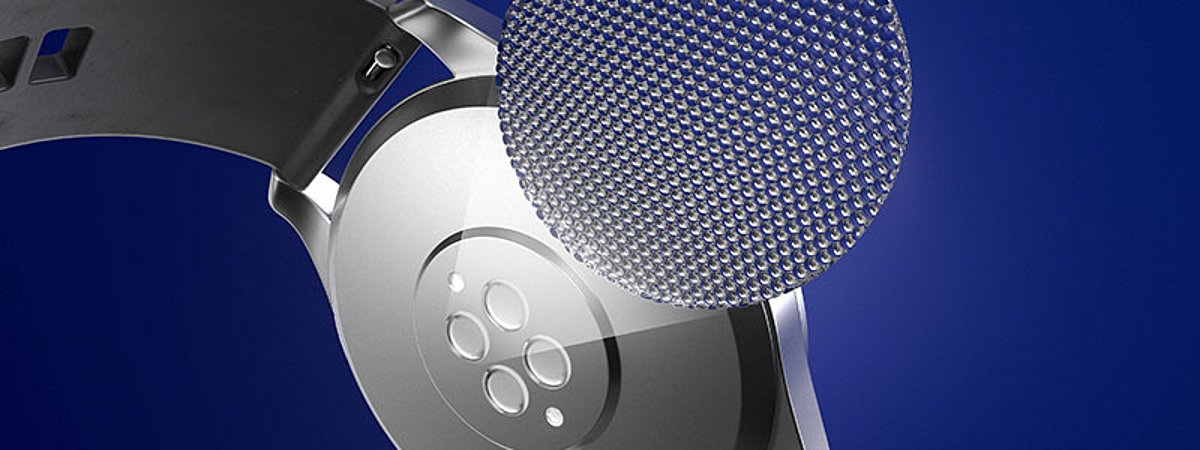

Vitralit UC 1633 belongs to the latest generation of optical materials: the adhesive is characterized by further improved resistance to yellowing, increased optical transmission and dimensional stability. It can be easily removed from PDMS molds, making it the perfect material for the production of microlenses, which are used in smartwatches, for example. For other optical applications and assembly, Panacol offers black UV-curable materials for shading and masking properties. These "Black&Light" adhesives, such as Vitralit BL UC 1103, can be cured in thicker layers by light only, resulting in optical densities of up to 6. For the assembly of optical components, Panacol offers a wide range of UV-curing adhesives for bonding and alignment. Dual cure UV adhesives with a secondary moisture or heat cure step are available for curing in shadow zones. These adhesives and materials for optical bonding are cured with high-intensity LED curing systems from Hönle, which are perfectly matched to the wavelengths of the Panacol photoinitiators. After curing, the Panacol adhesives for optical bonding are flexible and stress equalizing, which reduces the load on different substrates.