Dürr magnetic separator for cleaning process liquids

The EcoMagno from Dürr is an innovative magnetic separator that was previously used for cleaning process baths in the pre-treatment of car bodies. Thanks to its new mode of operation, the separation process no longer needs to be interrupted to remove the accumulated particles.

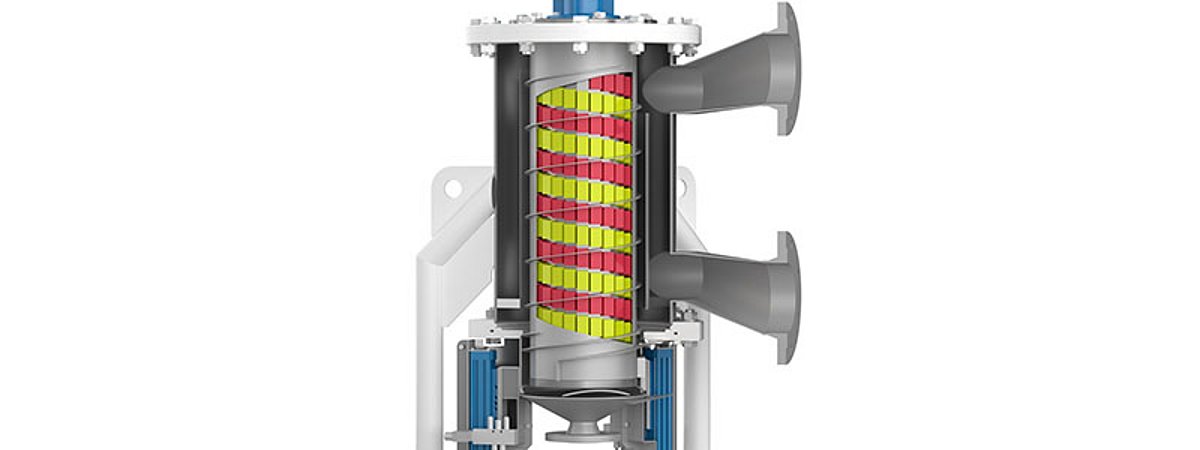

In paint shops for the automotive industry, car bodies are cleaned of grease, metal particles and other impurities during pre-treatment by transporting them through dip tanks with cleaning fluid. To ensure consistent cleaning, the process fluid in the tank must be cleaned continuously. This is the task of the EcoMagno magnetic separator. Dürr's patented innovation consists of a drum with neodymium magnets arranged in a spiral. The rotary movement of the drum transports separated magnetic particles continuously downwards towards the bottom of the container. In this way, almost 100 % of the magnetizable particles can be removed from the liquid.

Unlike conventional solutions, EcoMagno does not require the filtration process to be interrupted in order to remove magnetic particles. The particles on the cylinder surface are transported out of the tank by linearly moving magnets, so-called scrapers, during operation. This function, together with permanent, independent cleaning of the system, is unique on the market to date. Conventional products use bag filters with permanent magnets or automatic bar magnets that interrupt their function during cleaning. The pre-installed unit specially developed by Dürr can be easily integrated into an existing system. Thanks to its compact and efficient design, the magnetic separator can be installed and put into operation within a weekend. Only one power connection and two flange connections are required. The EcoMagno has already been successfully used around 80 times in the automotive industry. The magnetic separator requires a flow rate of 60 to 240 cubic meters per hour to clean the process tank. In other industries such as electroplating, machining or the food industry, however, flow rates of up to 20 cubic meters per hour are often sufficient. Dürr has therefore downsized the EcoMagno so that it can also be used in other industries.