Coatmaster pioneers spatial layer thickness measurement for prismatic battery cells

Coatmaster AG has introduced the Coatmaster 3D non-contact coating thickness measurement system, a novel solution to address the ongoing challenges in the production of prismatic battery cells for e-mobility. It uses advanced ATO technology for spatial measurement.

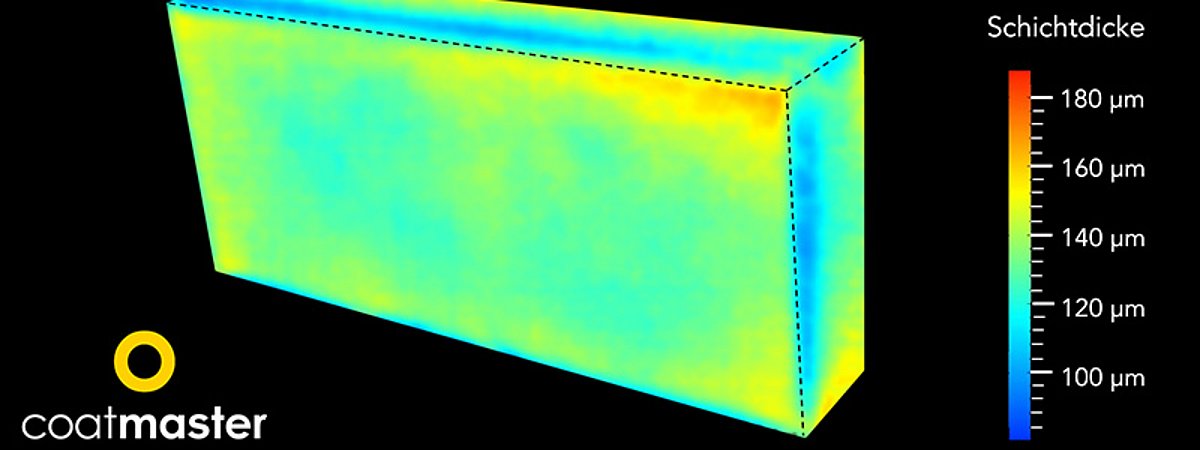

The production of prismatic battery cells, which are essential for the e-mobility industry, uses a specific cuboidal geometry. A key component of these cells is an insulating coating, the minimum thickness of which is critical to maintaining electrical isolation. However, industry-wide problems have plagued the accurate measurement and assurance of this minimum thickness, particularly at the cell edges. In addition, there are various factors such as viscosity, surface tension, curing behavior, edge curvature and the spatial spray pattern of the paint gun. Previous approaches attempted to measure the coating thickness at the lateral surfaces of the cell and to anticipate a correlation between these values and those at the edges. However, recent studies show only a weak correlation due to the variables mentioned above. Moreover, the position of the minimum thickness along the edges is not constant, which requires a spatial approach to measure the coating thickness. For these reasons, battery manufacturers perform additional visual inspection of the edges, which incurs additional costs and resources.

In response to this need, Coatmaster AG introduces the revolutionary Coatmaster 3D non-contact coating thickness measurement system. This state-of-the-art tool uses advanced ATO technology to enable spatial measurement of coating thickness across all side surfaces and edges within fractions of a second, ensuring uniform thickness throughout the cell. Several initiatives are already underway to replace the previous, inadequate measurement technologies with the novel coatmaster 3D solution. In a remarkably short time, coatmaster 3D has become the new industry standard. "Coatmaster 3D is a great leap forward in prismatic battery cell production," says Andor Bariska, co-CEO of Coatmaster AG. "It significantly improves not only efficiency and quality control, but also the safety and reliability of e-mobility solutions." Coatmaster's pioneering approach heralds a new era in prismatic battery cell manufacturing, according to the company, and underscores its commitment to continuously advancing industry standards.