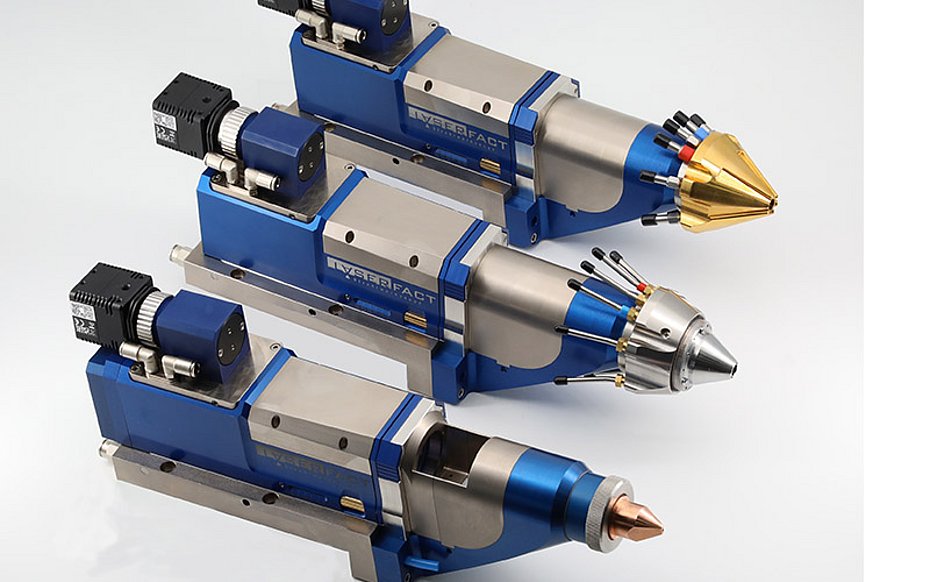

Competitive success in the global market requires innovative production solutions. Flexible production systems that use different machining processes can generate decisive competitive advantages. Shortening of process chains, higher plant efficiency and productivity as well as lower manufacturing costs are the key to success here. Tailor-made for the industrial use of laser technology as an established tool in metal processing, Laserfact GmbH bundles several laser beam processes in one tool - the combi-head: A laser optics for additive and subtractive laser processes.

Machining head as a tool for many tasks

Common laser beam processes such as cutting, welding or surface treatment use processing heads specially designed for these processes, a change between processes then requires a change and set-up of the processing heads associated with corresponding effort. This effort can be decisively reduced if the basic unit of the processing head remains mounted on the system and can be easily adapted to the respective processing task by means of different nozzle variants. Properties of a system with laser such as flexibility, productivity, accuracy or design freedom are used much better in combination with a higher economic efficiency. Laserfact GmbH works on shortening and integrating process chains by developing combined processes and tools.

The combi-head as the basis for flexible production

The idea of the combi-head is to combine laser cutting and welding with one tool. The working distance and the process gas are changed via a control system. The key component is the "autonomous nozzle"; the gas, e.g. nitrogen for fusion cutting, is fed to the cutting point via an annular channel. This is done without stressing the optical components. Cutting with the "autonomous nozzle" has marked the state of the art for a long time. By switching to an inert process gas and changing the working distance, the processing head is adapted to the welding application to be performed. This is done without mechanical set-up work and without subsequent adjustment of optical components. The combi-head can be optionally equipped with lens or mirror optics and is suitable for solid-state lasers as well as for CO2 lasers of high power and beam quality.

Extension of functionality through new modules

With the further development of existing processes and the development of new processes, the complexity of the plant equipment is also increasing. Laser cladding is one example of additive processes that are becoming increasingly important in industrial production.

Laser cladding

In classic laser metal deposition (LMD) welding with powder, the laser usually heats the workpiece defocused and melts it locally. At the same time, an inert gas mixed with fine metal powder is supplied. The effective area is supplied with the metal/gas mixture via coaxial nozzles or off-axis nozzles. At the heated area, the metal powder melts and bonds with the metal of the workpiece. Common speeds are a few millimeters to 20 m/min. The simple changeover with a coaxial HighNo powder nozzle module allows the combi-head to perform additive manufacturing and thus coating with the processing optics. With this module, the well-known laser cladding (LMD) but also the Extreme High Speed Laser Cladding (EHLA) further developed at Fraunhofer ILT are possible.

Extreme high speed laser buildup welding

The EHLA process operates at process speeds of up to 500m/min. In this process, the powder particles are already melted above the melt pool, so only liquid material droplets enter the melt pool. This is also reflected in the coating - it is smoother and purer. Roughness can be reduced to a tenth of the previous value. Whether corrosion or wear protection coatings - thin layers (25 - 250 μm) can be applied within a short time in a resource-efficient and, above all, economical manner using EHLA. The high process speeds coupled with very high powder efficiency and the subsequent low level of rework represent a real alternative to hard chrome plating and thermal spraying. Especially since the technological advantages of EHLA offer a significant upgrade for the industry. This is because pore- and crack-free coatings produced using EHLA protect the component much more efficiently and over the long term than conventional coatings.

The key component in EHLA is the powder feed, which is a powder nozzle with a unique concept that enables a powder efficiency of almost 100%. The integration of this nozzle into the combi-head is already state of the art.

Laser buildup welding of 3D contours

Instead of a coaxial continuous powder nozzle, full 3D manufacturing is also possible with a multi-jet nozzle (discrete). The "HighNo - 6" discrete powder nozzle is a robust solution for additive manufacturing with high application rates. Here, 6 powder gas streams guided coaxially to the laser beam generate a powder gas beam focus, which enable the application of 3D contours even in constrained positions. Due to the direct water cooling and the large nozzle distance (20 mm), it can be used with large laser powers (up to 20 kW). As a result, it is not sensitive to back reflection or flying back particles. The modular design of the nozzle allows the use of wear-resistant precision tubes (inlays) of various dimensions for variable powder gas beam foci. Depending on the application, larger powder mass flows and consequently thicker and wider layers can be applied. Customer replacement of the inlays is possible at any time with little effort and short setup times.

Laser buildup welding in hard-to-reach areas

The lateral powder nozzle ("Off-Axis") represents a light, simple and robust system, which is characterized above all by very good accessibility, even in extremely poorly accessible welding positions. The powder injection is a single powder-gas jet, which can be introduced at different angles and diameters. However, this does not make the powder feed directionally independent, and buildup welds are limited to simple, straight weld lines. Where the coaxial powder nozzles cannot be used due to their geometry, the off-axis powder nozzle is used.

Laser cladding of extremely small internal contours (LARS - Laser Aided Repair System)

For areas that are difficult to access, such as small openings or cross-sections that are not rotationally symmetrical, the LARS process represents a solution for coating. In order to be able to dip into small internal contours, both powder and gas supply, Crossjet and cooling are designed integrated in this module of the combi-head. The advantages of Laser Powder Bed Fusion (LPBF) as a generative process were used to produce this complex geometry. Here, so to speak, an additively manufactured component was used for another additive manufacturing process (LMD).

This newly developed internal coating unit enables, for example, the repair of an internal contour with a required coating depth of 70 mm. For this, positioning and twisting to a required dimension is possible and coatings with a total width of 9mm can be produced. With a small modification, this module can also be used for laser hardening of extremely small inner contours. (OM-07/23)

Technical features of the nozzle modules for the combi-head are:

- Plug-and-play solution for the industry

- On-site changeover in a very short time (exchange of nozzle modules in less than 2 minutes)

- Reproducible exchange of nozzle modules (qualification of nozzle tip modules possible)

- High wear resistance due to innovative surface treatment

- Powder focus diameter of 0.5 mm possible

- Different gap dimensions for high variability

- Different coaxial powder nozzles can be integrated, depending on laser power

The integration of laser cutting, welding and coating processes in a flexible, resource-efficient and freely configurable manufacturing environment based on combination processing creates new opportunities for intelligent process chains. In order to consistently exploit the advantages of laser system technology, which has become multifunctional with the combi-head, it is worth rethinking previous assembly designs that assume limited possibilities of conventional process chains. Such new developments lead to production engineering advantages in manufacturing such as:

- High productivity (short, integrated process chains)

- High flexibility and economical production of options and variants,

- High part and assembly accuracy due to short tolerance chains,

- Savings in handling, positioning, clamping operations, storage and transport times, production resources (incl. number of lasers, machines and floor space)

- High utilization of the production system incl. laser source

- Easy reconfigurability of the manufacturing system

In most applications, investment, organizational and operating costs are at least halved, while productivity, quality, flexibility and time-to-market are improved.

Contact

Laserfact - Strahlwerkzeuge GmbH

F. W.-Raiffeisen-Straße 31A

52531 Übach-Palenberg (Germany)

Phone: +49 2451 6169 989

E-Mail: contact@laserfact.de

laserfact.de