Adhesives that have the right mechanical properties such as strength or elongation for a specific application do not always harmonize with the material surface and therefore often do not achieve the required adhesive strength. If "the chemistry is not right", atmospheric plasma offers an efficient solution in many cases. Plasmatreat GmbH perfects the bonding of materials in many different applications with its innovative Openair and PlasmaPlus processes.

PlasmaPlus with PT-Bond: Reaction partner for the adhesive

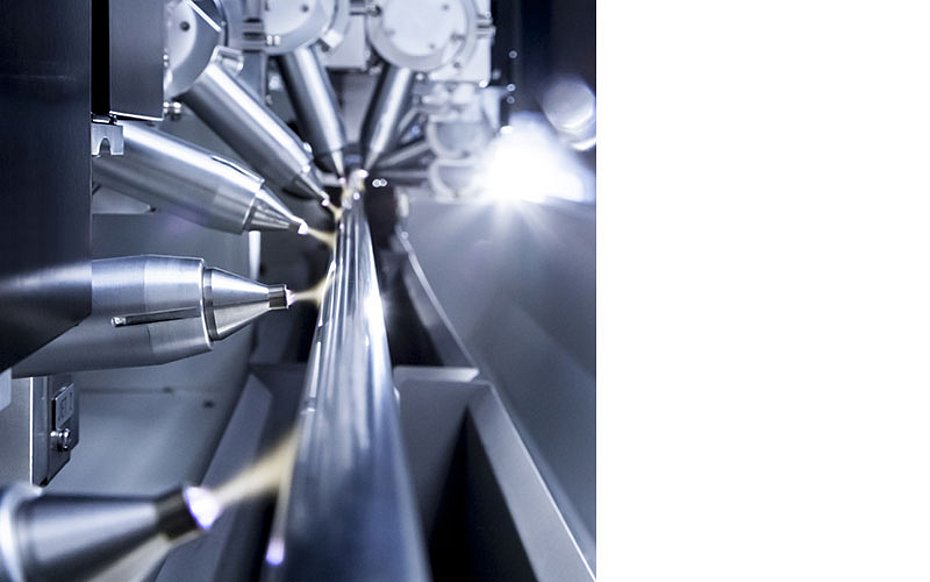

Plasmatreat provides highly effective and efficient support for industrial bonding processes with its innovative solutions: Ultra-fine cleaning with open-air plasma gently and safely removes dust, grease, organic release agents and additives from various surfaces. The introduction of oxygen- and nitrogen-containing functional groups into mostly non-polar materials, for example, leads to an increase in surface energy (activation) and thus to optimized wettability, which results in a significant increase in adhesion. The PlasmaPlus application PT-Bond for the nano-coating of surfaces, in which a gaseous precursor is injected into the plasma jet, significantly improves the processes when using various adhesives and sealants: it generates a sufficiently fast reaction at the interface between substrate and adhesive and provides the adhesive with a reaction partner on the surface with which it can react faster than with itself. In this way, a reliable, age-resistant bond is established. The VOC-free PT-Bond technology can replace almost all water- and solvent-based primers, making it an environmentally friendly solution that is also easy to automate and enables direct further processing of the substrate, as no drying times are required.

Optimization of bonding processes using the Openair and PlasmaPlus methods

Numerous application examples from the Plasmatreat portfolio demonstrate the optimization of industrial bonding processes using the innovative Openair and PlasmaPlus processes. For example, weather-resistant bonding with silicone of solar modules made of glass and aluminum or rotor blades made of glass fiber reinforced plastic can be achieved. High-quality bonding of plastic and glass for the manufacture of household appliances is also achieved, e.g. impact-resistant, durable bonding of plastic pan supports with tempered glass plates for gas stoves using heat-resistant silicone adhesive. In the production of technical outdoor lighting, plasma applications support, for example, the improved, weather-resistant adhesion of a PU sealing foam between glass and aluminum. Modern EPDM and PP door sealing profiles for the automotive industry are also applied to painted door surfaces with the help of plasma. In the electronics sector, the technology ensures reliable RTV or PUR adhesive seals that seal the housings of highly sensitive sensors. Medical technology also relies on plasma applications, including for the production of durable metal components overmoulded with plastic for medical devices such as heart-lung machines.

Plasma process only with compressed air as process gas and electrical energy

"The processes developed by Plasmatreat only require compressed air as a process gas and electrical energy, generate no VOC emissions (Volatile Organic Compounds) and in many cases replace the use of chemical adhesion promoters (primers). Innovative control systems ensure process control and reproducibility. They are therefore in great demand in a wide range of industrial processes to give adhesives with optimum mechanical properties significantly improved adhesion," emphasizes Klaus Kresser, Managing Director of Plasmatreat Switzerland AG and Global Market Segment Manager Bonding Applications at Plasmatreat GmbH. (OM-11/23)

Contact

Plasmatreat GmbH

Queller Straße 76-80

33803 Steinhagen (Germany)

www.plasmatreat.com

About Plasmatreat

Plasmatreat is an international leader in the development and manufacture of atmospheric plasma systems for the pre-treatment of material surfaces. Whether plastic, metal, glass or paper - the properties of the surface are modified in favor of the process requirements through the industrial use of plasma technology.