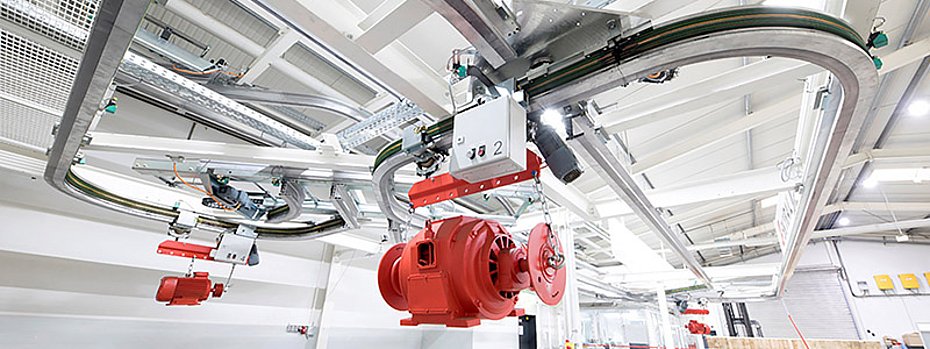

The ultra-light electric monorail system (EMS) Skyrail from SEH Engineering GmbH is not only versatile, but also sets new standards in terms of energy and resource efficiency. Its decisive advantage in this respect is that it consumes only 20 to 25 percent of the electricity of a classic C1 standard monorail system, which is widely used in the automotive industry in particular. This makes the innovation from Ostrhauderfehn the ideal system for transporting, sorting, storing and distributing goods weighing up to 500 kg in a two-axle vehicle and up to 1,000 kg in a four-axle vehicle. At the same time, thanks to the material-saving and installation-friendly Skyrail technology, an intelligent EMS is now also affordable and profitable for smaller and medium-sized operations.

Lightweight ESA with high energy efficiency

Increasing energy efficiency has long been a trend in intralogistics. Among other things, this is related to the high power consumption of industrial conveying technologies, which stems from the use of the large quantities of electric motors. The current energy crisis is giving this topic an additional boost, the effects of which are not yet foreseeable. In this respect, the engineers at SEH Engineering acted with great foresight when they designed and constructed the lightweight EHB Skyrail two years ago. "In developing Skyrail, we placed a lot of emphasis on resource-saving functionality and high energy efficiency," emphasizes Carsten Schmidt, managing director of SEH Engineering's Conveyor Systems division in Ostrhauderfehn.

Skyrail vehicles can handle vertical travel on inclines of up to 30 degrees without spring-actuated counterpressure rollers. Thanks to the innovative system concept patented by SEH Engineering, they manage with considerably less tractive force than the vehicles of a C1-EHB. Despite the transport capacity of up to 500 kg in the two-axle vehicle, they also weigh less dead weight (namely only 50 kg) that has to be moved. That's why, with Skyrail, engines with far less power are sufficient to accelerate to speeds of up to 150 meters per minute. What's more, where their C1 counterparts need two drives, Skyrail vehicles only need one. All in all, these design advantages result in energy savings of 75 to 80 percent. In return, this means that vehicles of a C1 EHB have a power requirement that is 4 to 5 times higher. In a materials handling system with often several hundred vehicles, this difference in power consumption makes itself felt considerably. Users who opt for the new Skyrail system will benefit from a massive increase in energy productivity.

Reduce expenditure for steel construction and assembly services

In addition to the economical use of energy, the Skyrail system has the advantage of requiring only minimal steel construction. The aluminum rails, which are mounted directly on the hall steel structure with twelve hollow chambers including clamp connections, span up to six meters. This is twice as much as a C1-standard EMS. In times of high steel prices, this difference is particularly worthwhile, as it significantly reduces the cost of steel construction and erection work. According to Carsten Schmidt, costs can be reduced by up to 40 percent compared with a C1 EMS.

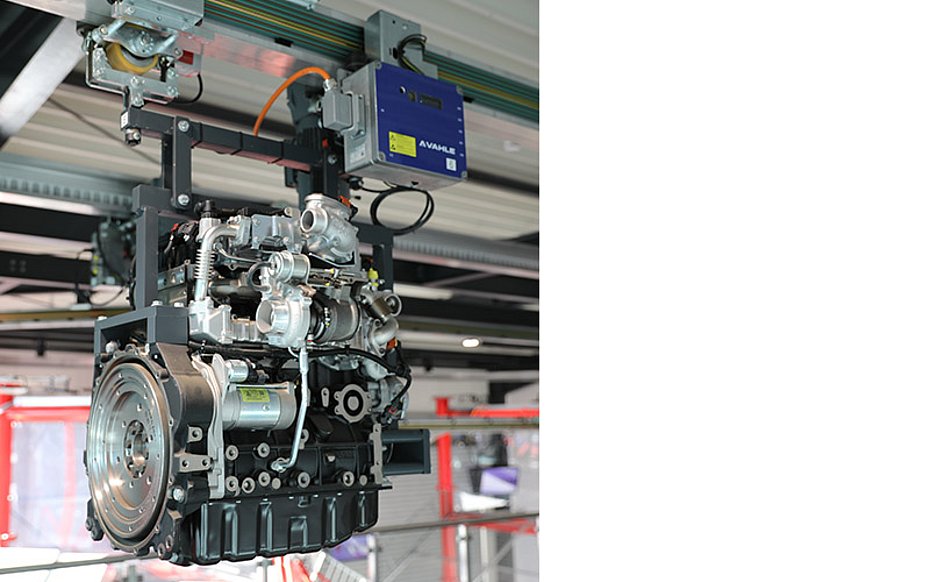

Although SEH Engineering designed Skyrail primarily for non-automotive applications and rather for small and medium-sized companies, the automotive industry has now also recognized its plus points. For example, in the final assembly of a northern German automotive plant, the EHB system is used for the electrical commissioning of cars coming off the assembly line. This is where its ergonomic advantages come into play: The transport unit lowers the vehicle by means of a telescopic arm to make the terminals and plugs for the power supply readily available to the worker. (OM-04/23)

Contact

SEH Engineering

Im Gewerbegebiet 2a

26842 Ostrhauderfehn (Germany)

Tel.: +49 4952 807-0

seh-engineering.de

About SEH Engineering

SEH Engineering GmbH, headquartered in Hanover, specializes in steel construction, special design, bridge construction and corrosion protection. The Conveyor Systems division, based in Ostrhauderfehn, designs and implements individual solutions in the field of overhead and floor conveyor technology as a full-service package. The roots of SEH Engineering go back to 1808. Since 2007, the company, which has a turnover of 110 million euros and 270 employees (in 2021), has been a subsidiary of the French Eiffage Group.