The pressure to automate in industry is increasing and the use of robotics is becoming ever more important. At the same time, qualified specialists for robot programming are hard to find. Plant manufacturer Robert Bürkle from Freudenstadt in Baden-Württemberg is now solving the problem in its customer projects with the SRCI interface, which allows simple programming directly in the PLC.

Simple robot programming even for SMEs

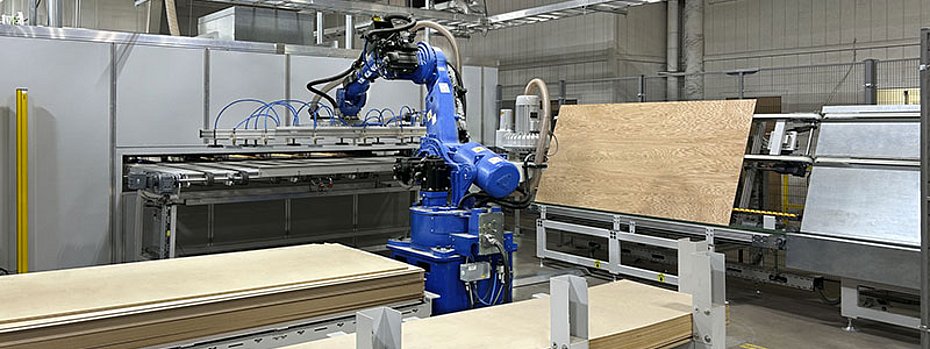

Laminators for credit cards and photovoltaic modules, coating systems for the furniture industry and everything to do with wood processing: the product range of Robert Bürkle GmbH from Freudenstadt is diverse. Among other things, the company specializes in press and coating technologies for flooring, doors and wood-based panels, and its portfolio also includes rolling, casting and spray painting systems. In wood processing in particular, the plant manufacturer often has to deal with heavy workpieces. These include lightweight panels for the caravan industry, which weigh between 180 and 250 kilograms - and are therefore too heavy for a person to handle. "With these requirements, it was unavoidable to incorporate robots into new system concepts," recalls Marian Michels, who has been working as a PLC programmer since completing his electrical engineering degree in 2018. Customers are increasingly demanding robotics and automation. The crux of the matter: programming robots requires trained specialists who are difficult to find on the market. The obvious solution for Michels was to program the Yaskawa robots installed in the plant itself - thanks to the new SRCI interface.

Simple programming directly in the PLC

SRCI stands for Standard Robot Control Interface. Robert Bürkle is one of the first pilot companies to use the new interface. The SRCI concept is very intuitive: thanks to the interface, programming can take place directly in the programmable logic controller (PLC) - specific knowledge of the robot manufacturer's systems is no longer required. The interface offers a library of PLC function blocks, also known as a library, for various robot functions.

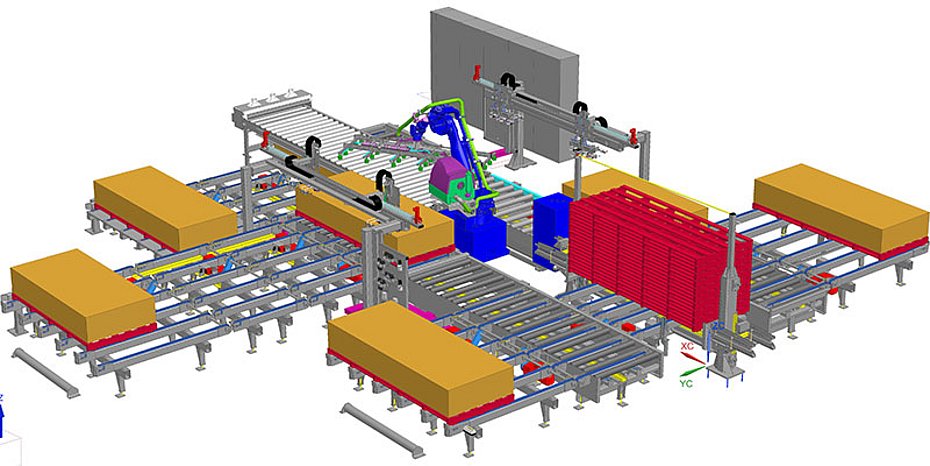

Robert Bürkle benefited from the pioneering spirit of his robot supplier during development. "Yaskawa took the topic seriously right from the start and played a key role in driving the development forward," explains Bertus de Groot, Application Engineer at the Robotics Division of Yaskawa Europe. The idea for SRCI goes back to an initiative by Siemens. Since 2018, the PLC manufacturer has set up a comprehensive committee of robot manufacturers, developers and users under the coordination of the Profibus & Profinet International (PI) organization. After several years of coordination, SRCI is now ready for the market, as the joint project between Yaskawa and Siemens at Robert Bürkle has shown. The plant manufacturer is now optimizing its systems using a digital twin. The virtual image allows the design engineers at Robert Bürkle to make better use of the available resources in programming and save a lot of time. The panels processed in the system are three meters long and one meter wide; any test run with real material on the system would involve a great deal of effort. "In addition, design and fine-tuning are more efficient," says Marian Michels.

Also suitable for smaller companies

Despite careful preparation, the first acid test for the digital twin was the virtual commissioning of the latest system. This involved integrating the Yaskawa robot used into the PLC program, including testing the correct mode of operation and the work areas. Robert Bürkle installed the Motoman GP225 handling robot with a payload capacity of up to 225 kilograms and a maximum working range of 2,702 mm in the system. The medium-sized company had already been convinced by Yaskawa at an early stage, which is why it was very open to the new programming option. "SRCI was simply an invaluable advantage," recalls Michels. The PLC programmer was able to work in his familiar environment - and complete commissioning quickly. Despite the manufacturer independence, the Yaskawa motion control and path accuracy are now retained in the system. The multi-axis and multitasking-capable Motoman YRC1000 controller and the YRC1000micro compact controller for robots weighing up to twelve kilograms are currently supported. Small companies in particular benefit from the interface. "SRCI is the right solution for smaller customers who don't want to program everything themselves," says Yaskawa expert de Groot. Although robots are becoming increasingly important in plant engineering, commissioning robots is not part of everyday life for SMEs like Robert Bürkle. "Due to its simplicity, the interface is the best and quickest way to use robots at this size of company," explains programmer Michels. After all, it is not possible to have the capacity on site in Freudenstadt to bring in a large number of robot experts.

Nevertheless, Marian Michels has already convinced some of his colleagues at SRCI. As the main person responsible for robotics, he gives training courses and explains how to work with the interface in-house. The feedback from his colleagues is positive: "The learning curve is very manageable," says Michels. Programming with SRCI is so easy at Robert Bürkle that after the first steps with two robots, there are now already five robots in the hall. "We can now offer more difficult robot applications with a clear conscience," says the programmer.

MotoLogix continues to play an important role

Marian Michels and Bertus de Groot are convinced that the importance of SRCI in industry will increase significantly in the coming years. The deep integration of robots into existing development environments for PLCs and HMIs, the low programming effort and simple virtual commissioning are the key to this. However, this does not mean that existing programming options will be replaced. Yaskawa has been offering its own MotoLogix solution, a software interface for teaching and programming robots using PLC function blocks, since 2015. MotoLogix is primarily used by larger OEMs who have more time and expertise for robot programming.

Lots of innovative spirit at Bürkle in Freudenstadt

Robert Bürkle has also already implemented several projects with MotoLogix. "The company is always a pioneer when it comes to using new technologies," says de Groot. The Black Forest-based company is very satisfied with the SRCI projects implemented to date. The close cooperation between the companies involved was central to the success. "We had a direct line into development," recalls Marian Michels. Together, they also identified challenges and found solutions. When more robots are installed in the large systems in Freudenstadt in the future, Marian Michels and his colleagues will be able to rely on the support of Yaskawa (OM-7/25).

Contact

Yaskawa Europe GmbH

Robotics Division / Allershausen site

Yaskawastraße 1

85391 Allershausen (Germany)

Phone: +49 8166 90 -0

Mail: robotics@yaskawa.eu

www.yaskawa.de

About Yaskawa

Yaskawa is one of the largest manufacturers of industrial robots. In addition to application-specific variants such as welding, palletizing, painting and handling robots, the extensive range of robots also includes models for laboratory and clean room applications as well as turnkey automated welding systems of the highest quality.