The German mechanical engineering industry often operates completely outdated paint shops or relies on external contract coaters. In order to increase flexibility, efficiency and resilience, the industry should invest in future-proof systems, as experts from Fraunhofer IPA now explain in a white paper.

The company LHY Powertrain, formerly known as Linde Hydraulics, manufactures pumps, motors and valves in Aschaffenburg. The finished products are wet-painted largely automatically in the company's own paint shop. But this was not always the case. Until 2016, the company entrusted an external contract coater with this final production step - with all the consequences: There was a lack of flexibility, control and influence in the event of quality defects and complaints, as well as a lack of in-house expertise in this area. Higher quantities inevitably led to rising transportation costs and greater planning effort in logistics. The company had become dependent. Like LHY Powertrain at the time, many mechanical engineering companies still work with contract coaters today and are ultimately not in control of the wet painting or powder coating of their own products. And this is also widespread in the industry: Painting systems from the eighties or nineties - hopelessly outdated. "With such systems, it is no longer possible to improve product quality and respond to increased market demands," warns Volker Wegmann from the Fraunhofer Institute for Manufacturing Engineering and Automation IPA. "This makes the painting process a bottleneck in the value chain."

White paper on sustainable painting in mechanical engineering

"It's time for mechanical engineering to pay more attention to painting technology, bring the relevant expertise into their own companies and set up future-proof painting systems," advises Oliver Tiedje, Head of the Coatings and Multifunctional Materials Business Unit at Fraunhofer IPA. Together with Wegmann and other colleagues, he has therefore written the recently published white paper "Future-proof painting in mechanical engineering". In it, the authors not only explain in detail the advantages of a proactively planned in-house painting system, but also show which skills are important.

"Paint shops are often in operation for 30 years," says Wegmann. "So you not only have to know the current state of the art, but also be able to assess which new processes and materials will be available in the future. In addition, specialist knowledge from several scientific disciplines flows into the planning process: Engineering, chemistry, physics, often also biology - and business administration, because of course the plant also has to be profitable." Sound knowledge instead of gut feeling.

Research team plans energy-efficient and flexible wet painting system

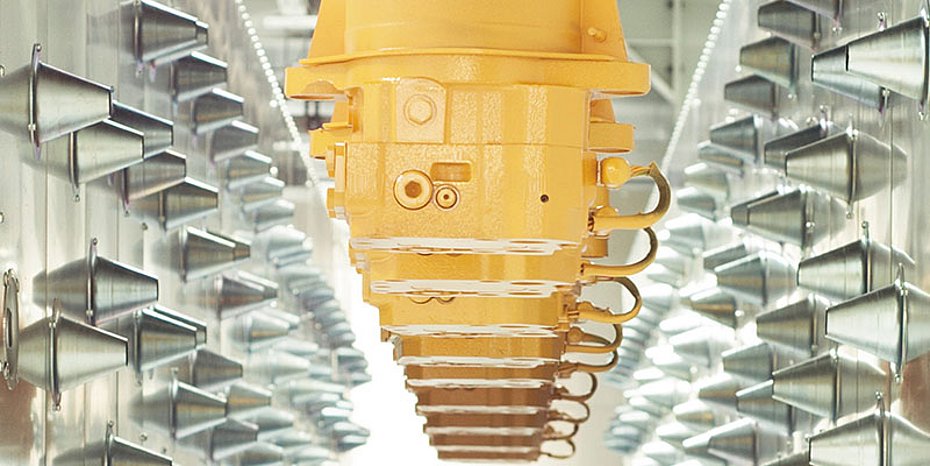

When LHY Powertrain commissioned Fraunhofer IPA to plan a future-proof paint shop for the company, an interdisciplinary research team first drew up a list of requirements with all the criteria that the system should meet. The scientists then began with the actual planning. The result was an energy-efficient and flexible wet painting system with "Power & Free" conveyor technology including a color sorting buffer, nine-zone pre-treatment and high-rotation atomizers with color change in the robot arm including pigging technology to reduce material losses. A combined adhesive water and top coat dryer with several lines for drying thin and thick components as well as a vision system for workpiece recognition and paint program creation were also integrated into the system.

"Planning a future-proof coating system is not an insurmountable problem and, above all, not something that should be put off for too long," says Wegmann. "And if you want to be on the safe side, you can get help." (OM-2/25)

White paper "Sustainable painting in mechanical engineering"

The white paper "Future-proof painting in mechanical engineering" is available to download free of charge.

Contact

Fraunhofer Institute for Manufacturing Engineering and Automation IPA

Nobelstr. 12

70569 Stuttgart (Germany)

www.ipa.fraunhofer.de

About the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA)

The Fraunhofer IPA was founded in 1959 and employs almost 1200 people. The focus of research and development is on organizational and technological tasks in production. Methods, components and devices through to complete machines and systems are developed, tested and used as examples. The 19 specialist departments of the Fraunhofer IPA cover the entire field of production technology and work on an interdisciplinary basis with industrial companies in the automotive, mechanical and plant engineering, electronics and microsystems technology, energy, medical and biotechnology and process industries.