Climate protection is increasingly determining product development in mechanical and plant engineering. This is particularly true for innovation-oriented companies like the Dürr Group: With new technologies, the world market leader is paving the way for climate-neutral painting of cars. The focus here is on the intelligent use of energy and the use of green electricity instead of fossil fuels. The Dürr Group is also improving its own climate footprint. In 2022, CO2 emissions fell by a good 40 percent because the company relies on green electricity and invests in photovoltaics.

Sustainable operation of the paint shop possible

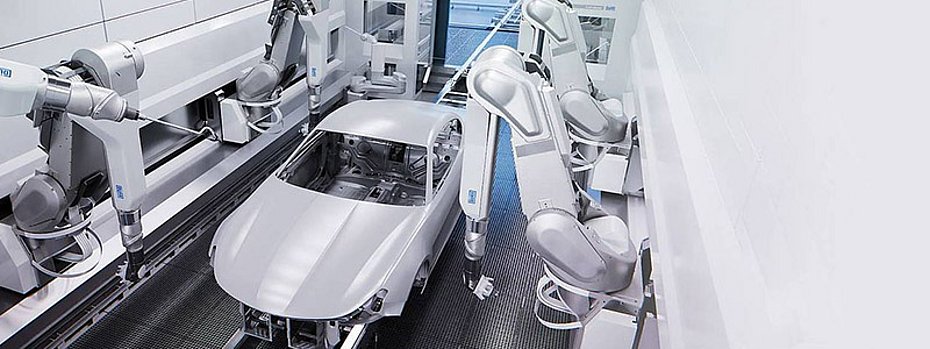

"We can already build CO2-free paint shops for our customers today," says Dr. Jochen Weyrauch, CEO of Dürr AG. The company is taking a two-pronged approach: On the one hand, it offers plants that can be operated with green electricity instead of natural gas. On the other hand, it is focusing on using energy even more efficiently. This benefits the automotive industry in several ways: manufacturers reduce their energy costs, can operate their paint shops sustainably and are thus able to achieve their climate targets more quickly. "We help our customers deliver on the promise of decarbonization," says Dr. Jochen Weyrauch. The paint shop is the area of automotive production that is particularly important for decarbonization. This is because over 40 percent of the energy required by an automaker in its plants is used in the painting process. For example, drying the car bodies or air conditioning the paint booths are energy-intensive processes. Dürr can make a correspondingly strong contribution to reducing greenhouse gas emissions in the automotive industry with new technologies.

Dürr is currently building an almost CO2-free paint shop for a German car manufacturer. In it, dryers and exhaust air purification systems are heated entirely with electricity from renewable energy sources. Dürr is also using the EcoQPower intelligent energy network for the first time. It ensures that heat and cold generated during plant operation are not lost, but go to where they are useful for heating or cooling. At the heart of this combined heating and cooling system are heat pumps, water circuits and intelligent software.

Sustainable manufacturing processes for sustainable products

Energy- and emission-optimized plants are often installed in factories for electric cars. After all, cars that driveCO2-free should also be built with low emissions, according to the will of manufacturers and buyers. The Dürr Group has also adapted to electromobility beyond this and is developing special technologies for building e-cars. Examples include test rigs for electric motors and manufacturing technology for battery cells. In 2022, incoming orders with production systems for e-cars grew by over 40% to more than € 1.1 billion. Orders from the battery sector exceeded € 100 million for the first time, as Dürr is supplying several new Giga Factories in Europe with solvent recovery equipment.

"We are strategically focusing on technologies for manufacturing sustainable products for a largelyCO2-free society," said Group CEO Dr. Jochen Weyrauch. "In doing so, we are not only focusing on electromobility and the automotive industry. In other sectors, too, we are supporting the transformation to climate-friendly products through appropriate manufacturing processes." For example, the Group subsidiary HOMAG is expanding its business with production plants for climate-friendly wooden houses. Automation specialist Teamtechnik, which has been part of the Dürr Group since 2021, received its largest-ever order for production equipment for solar modules in 2022. Dürr is also on course for growth in environmental technology, for example with exhaust air purification systems for chemical and pharmaceutical production.

Carbon footprint improved: a good 40 percent fewer CO2 emissions than in 2021

At its own sites, the Dürr Group is also investing in climate-friendly technologies. In 2022, factory and office buildings in Germany, China and Spain were equipped with photovoltaic systems. Charging stations for electric company cars went into operation in many places. In Germany, India, Canada, Mexico, Brazil and the USA, the switch to green electricity was made, with all other sites following suit in 2023. Oil and gas consumption fell by around 10% in 2022. Dr. Jochen Weyrauch: "The credo of our climate strategy is: invest instead of compensate. We prefer to invest in climate-friendly technologies and energy rather than in compensation certificates, some of which have a dubious reputation."

With its climate investments and improved energy mix, the Group is well on its way to achieving the goals of its climate strategy. In 2022, greenhouse gas emissions directly attributable to the company fell by just over 40% year-on-year (Scope 1 and 2). Compared with 2019, the decrease was around 50%. The Group thus exceeded the target of 40% and has already achieved the majority of the 70% reduction targeted by 2030. The energy intensity of the operating business also improved significantly. In 2022, 14% less energy had to be used to generate one million euros in sales than in the previous year. As a result, the Group's energy consumption only increased by around 5%, while sales increased by 22%. (OM-3/23)

Contact

Dürr AG

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen (Germany)

Phone +49 71 42 78 0

corpcom@durr.com

www.durr.com