Painting with nitrogen for optimum surface finish

Painting with nitrogen as the atomizing gas as opposed to compressed air guarantees an optimum surface finish and effective cost and material savings. The spray pattern becomes much more uniform and fine, defects such as "orange peel" or "runner formation" are avoided.

For decades, the Bielefeld-based company Oltrogge GmbH & Co. KG has been developing tailor-made painting solutions for every surface, for every area of application and for almost every industry, thus providing its customers with clear competitive advantages. The innovative solutions include the use of nitrogen as an atomizing gas in wet painting. The physical properties of nitrogen achieve a particularly fine and efficient atomization of the material, as required, for example, in automotive painting.

Faster and better results through nitrogen use

The effect of using nitrogen as an atomizing gas compared to conventional painting with compressed air is immediately apparent: Due to the much finer structure of the gas, it is possible to work with less pressure in the system. On the one hand, this increases the application efficiency and, on the other, reduces overspray. Tests in practice have shown that paint stores can save up to 20 percent in material and thus cash.

Another qualitative advantage compared with a conventional process operated purely with compressed air is a constant atomizing gas quality that ensures a much more uniform fine spray pattern. Painting defects such as "orange peel" or "runner formation" are thus permanently avoided. This effect simultaneously shortens exhaust and drying times, streamlines processes, and leads to additional time and cost savings.

Painting system can be easily and inexpensively retrofitted

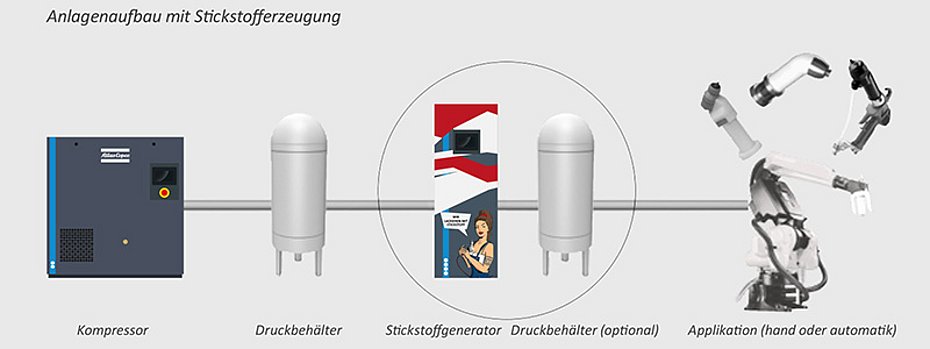

Owners of paint stores who now fear a major investment can rest easy. The technology can be used for all air-atomizing painting processes and wet paints and can be retrofitted to existing systems at any time. A complete new installation is therefore not necessary. For the installation in the own production, a nitrogen generator, for example from Oltrogge partner Atlas Copco, is installed between the air compressor and the (manual or automatic) application. This so-called membrane generator filters or concentrates the nitrogen via a membrane constellation through which the previously cleaned compressed air can flow. It is then available as stored process air for the painting process.

Interested parties who want to convince themselves of the surface quality and material savings can easily test painting with nitrogen before making a purchase. Via Oltrogge, a nitrogen generator of the Atlas Copco brand can be borrowed free of charge and painting with nitrogen can be tested in the own halls. Delivery, installation and commissioning are carried out at cost. (OM-07/23)

Contact

Oltrogge GmbH & Co KG

Finkenstraße 61

33609 Bielefeld (Germany)

Tel.: +49 521 3208 0

www.oltrogge.de

About Oltrogge

Founded in 1866, the Bielefeld-based company Oltrogge GmbH & Co. KG today develops and implements efficiency-enhancing solutions for existing or new production routes in industry. With four locations nationwide and expertise from over 150 years in the fields of surface, compressed air and welding technology as well as machine tools, the company supports its customers directly on site.