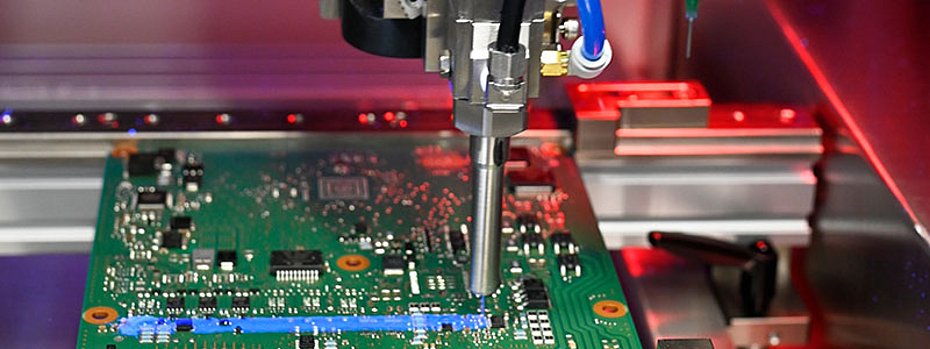

With the MYC10 high-precision coating system, Lackwerke Peters has acquired a high-performance piece of equipment. "The smart machine is almost half the size of the large industrial plants," says Johannes Tekath, laboratory manager at Peters Research. The production from the high-tech development of the Swedish company Mycronic completes Peters' technical center and is likely to be an eye-catcher at the next Peters Coating Innovation Forum. Mycronic has achieved this great feat through a cooperation with an Asian manufacturer.

Investment in new coating machine for electronic assemblies

Background: The coating and thus the protection of electronic assemblies is becoming increasingly complex and demanding. As early as the 1980s, Peters was a pioneer in the development of high-quality protective coatings for printed circuit boards and also in their application. In the beginning, the assemblies were still completely dipped, usually in Knödel's dipping systems. This was a challenge with regard to covering connector strips and other sensitive areas. In the second step, the protective coatings were selectively applied with intelligently used robot technology. Various such coating systems from well-known manufacturers have been in the laboratory and pilot plant for years.

With the MYC10 now acquired, Peters has once again invested in coating technology and has an additional option. The coating machine from Mycronic enables the use of common coating heads for spraying, dispensing and casting in a very confined space. "With the MYC10, our development department can fine-tune the Elpeguard protective coatings to achieve the best coating results," says Johannes Tekath.

Use in the development of protective coatings

Before the new machine is used in the development of protective coatings in the Peters laboratory, the development team is instructed in the control and programming functions by the manufacturer Mycronic. For Johannes Tekath, it is obvious what the advantages of the MYC10 are: "All important coating parameters of the coatings are determined precisely and quickly, so that they can also be used in large machines." Thus, according to the experienced engineer, from now on it does not matter which machine the customer or manufacturer has. "In addition, handling is easier and the coating effort is smaller for sample coatings."

Conclusion: coating development is accelerated with the MYC10. The intelligent coating meets the highest industrial standards. As a result, more sustainable application is also made possible in the laboratory, because dipping and manual spraying of test assemblies are no longer necessary. (OM-12/22)

Contact

Lackwerke Peters GmbH & Co. KG

Hooghe Weg 13

47906 Kempen (Germany)

Tel: 02152 2009-0

E-mail peters@peters.de

www.peters.de

About Peters Lacke

Peters Group, based in Kempen on the Lower Rhine, is an independent family-owned company and the world's only full-range supplier of coating materials for electronics. The company produces coatings for the manufacture of printed circuit boards and the protection of assemblies and electronic components through to integrated solutions for coating technology.