High quality bathroom furniture made of wood with noble lacquer surfaces

A furniture manufacturer creates noble lacquer surfaces for its high-quality wooden bathroom furniture through a mix of precision craftsmanship and high-tech. A high-quality water-based UV coating system with double hardening helps to achieve this.

There are many traditional companies. But a success story spanning more than 270 years - that is something of a rarity. Villeroy & Boch was founded exactly 274 years ago - 274 years in which the ceramics manufacturer has developed into one of the world's leading full-service providers for bathrooms and wellness as well as dining and lifestyle. As a full-range supplier, Villeroy & Boch not only provides washbasins, bathtubs and sanitary fittings, but also the matching furniture - all with maximum design and product quality. Around 50,000 pieces of furniture are manufactured annually in Mondsee, Austria: with precision craftsmanship combined with high-tech and with high-quality materials from wood to finishing with coatings from Adler Lacke.

Tradition and innovation

Like the family-owned company Villeroy & Boch, the associated furniture factory in Mondsee is also a traditional business: founded in 1890 as a classic village carpenter's workshop, expanded in 1972, and since 1991 a central production site for Villeroy & Boch bathroom furniture. "The scent of tradition, the spirit of the future": true to this motto, the company relies on a mixture of handcrafted and automated processes that precisely interlock - "this allows us to ensure our high quality standards and at the same time efficiently produce a very complex range with a variety of designs and materials," explains Herbert Stabauer. The trained master carpenter has been with the company for over 40 years and is now responsible for bathroom furniture production at Villeroy & Boch in Mondsee as Managing Director and Plant Manager.

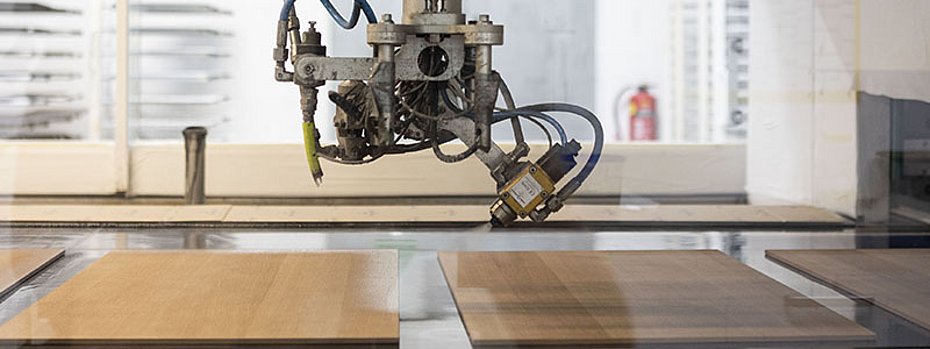

What this finely tuned interaction of manual and machine work looks like becomes clear on a tour of the plant: The handling of the panels - more than 200 different materials are in stock -, cutting and sanding are largely done with machine power. A robot takes the panels from the horizontal storage area and brings them to the fully automatic saw, an edge gluing machine, a CNC router with automatic 68-cavity tool changer and an automatic sanding machine take over the other work steps. But sometimes a delicate touch is also required - for example, the solid wood edges are sanded by hand in order to achieve optimum edge coverage during the subsequent lacquer application.

Double holds better

In coating, too, automation thanks to modern equipment and genuine, qualitative craftsmanship go hand in hand. Parts with complex geometries or very small batch sizes are coated by the team at the spray booth, manual work is also sometimes required for intermediate sanding, and the trained eyes of experienced employees are responsible for the final quality control of the coated surfaces. In addition, a UV coating system with a fully automatic painting machine ensures perfect surfaces in the shortest possible time. The system first cleans and de-ionizes the panels and then uses a 3D scanner to calculate the geometry of the workpiece - the prerequisite for optimum coating application. The guns of the automatic coating machine then coat the surface and edges with the high-quality water-based UV coating system Pigmolux DC from the Austrian manufacturer Adler. "DC", which stands for "dual cure" - namely, the coating is doubly cured: "A classic hardener on the one hand and UV radiation on the other enable optimum crosslinking of the coating. This guarantees fast throughput times and the resistance, elasticity and wet adhesion that are particularly important for bathroom furniture," explains Adler sales manager Christian Schütz. In cooperation with Adler technicians, the water-based UV coating was optimally adjusted to Villeroy & Boch's requirements - "thanks to the particularly fine coating structure, the surface achieves optimum anti-fingerprint properties and very good glossing behavior," reports Schütz.

Sustainable all around

In addition to the surface quality, the Adler coating also impressed Villeroy & Boch with its efficiency: "With Pigmolux DC, we can work with a single-layer structure without compromising on surface quality," says Herbert Stabauer. This speeds up the production process and reduces energy and material consumption - an important contribution to sustainable production. "The topic of sustainability is generally very important to us," emphasizes Stabauer. This also involves, but is by no means limited to, environmentally friendly materials and processes. Careful use of resources is also important to the family-owned company. Want to see some examples? An optimization computer reduces waste during panel cutting. At the other end of the production process, the packaging carton is custom-made for each piece of furniture - this saves material and reduces transport damage to almost zero.

The paint shops are equipped with a water sprinkler system fed from a 30,000-liter rainwater tank. "This has enabled us to halve our water consumption and also reduce the amount of cleaning required thanks to the low lime content," says Stabauer. But also a clear commitment to the Mondsee site with its approximately 100 jobs, the coverage of the electricity requirement to 100 percent from hydropower or the cooperation with a regional forwarding partner are part of the sustainable self-image of Villeroy & Boch. The fact that the paint manufacturer Adler is only a good two-hour drive away in Schwaz, Tyrol, fits perfectly into this concept. Herbert Stabauer emphasizes: "At Villeroy & Boch, we do not do things by halves - we always set the bar high for ourselves, but also for our partners. Adler has similarly high standards as we do when it comes to quality, innovation and sustainability - that's a good basis for a reliable partnership." (OM-07/23)

Contact

Adler-Werk Lackfabrik Johann Berghofer GmbH & Co KG

Bergwerkstr. 22

6130 Schwaz (Austria)

Tel.: +43 5242 6922

E-mail: info@adler-lacke.com

www.adler-lacke.com

About Adler Coatings

With around 670 employees, Adler is Austria's leading manufacturer of varnishes, paints and wood preservatives. Founded in 1934 by Johann Berghofer, the family-owned company is now managed by the third generation, Andrea Berghofer. 22,000 tons of paint leave the Schwaz plant every year and go to customers in over 30 countries worldwide. Adler has sales companies in Germany, Italy, Poland, the Netherlands, Switzerland, the Czech Republic and Slovakia.