Vibratory finishing technology for aerospace engineering

Vibratory finishing technology for aerospace engineering enables reproducible finishing processes with high precision and process stability in aviation technology. For safety-relevant components, scrap is reduced while quality and traceability are increased.

In the field of aviation technology, precision and safety are paramount, especially when it comes to Class A parts such as rotating engine components. These highly sensitive components, whose failure can have serious consequences, require not only exceptional process accuracy, but also maximum stability and traceability. With its state-of-the-art mass finishing technology, OTEC offers a pioneering solution to meet these challenges and significantly increase productivity at the same time.

Innovative finishing systems

The finishing systems from OTEC set new standards by enabling a seamless connection to production databases. This ensures that the systems always work with precise, component-specific process parameters. This eliminates incorrect manual interventions and significantly reduces reject rates. As sensitive components such as turbine disks can cost up to 60,000 euros, this process reliability is invaluable. The technology is complemented by seamless traceability at serial number level, which means that every processing step is documented.

The process stability of OTEC systems is guaranteed at all times thanks to intelligent media management, which monitors process parameters such as speeds and dosing of water and compound. Unlike with outdated machines, there is no need to constantly adjust process times as these remain stable. This makes the technology not only efficient, but also low-maintenance.

Automated and reproducible machining of large components

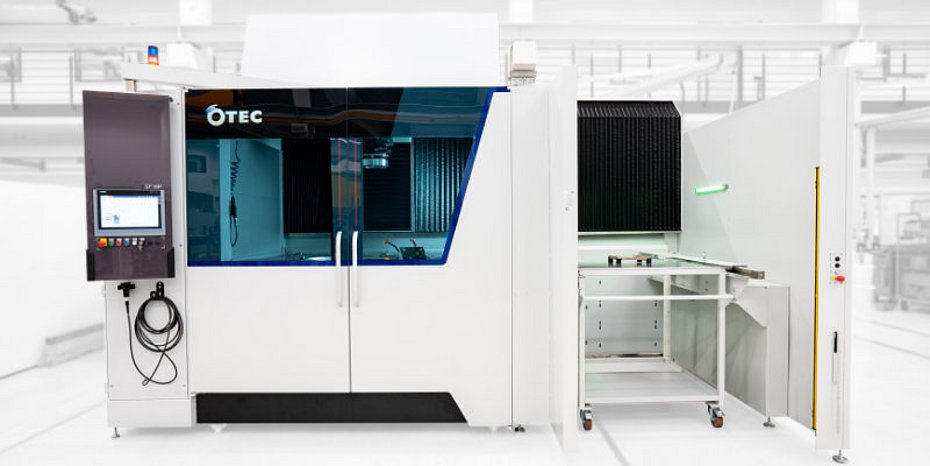

One of OTEC's key competitive advantages is its ability to process large and heavy components automatically and reproducibly. The SF-HP system, specially developed for such applications, is currently the world leader and enables integration into Industry 4.0 environments. This combination of technical innovation and industrial networking is unique and sets standards for the next generations of manufacturing. However, systems from the SF series also offer an optimal solution for smaller components and can be integrated into almost any process.

Technology for leading aviation technology company

The success of this pioneering technology is demonstrated by numerous projects that have been implemented. At a renowned German manufacturer, for example, older systems were replaced by OTEC systems, which led to a considerable improvement in the process. Approvals from major and international OEMs confirm the technical advantage of OTEC systems. By the end of 2026, three of the world's largest OEMs are expected to use OTEC systems for engine applications.

"Our technology has already been approved by leading aerospace companies. It not only ensures the highest quality, but also reduces long-term costs by minimizing scrap," explained Adrian Kofler, responsible for aerospace applications at OTEC. OTEC also offers the possibility to develop customized solutions for specific requirements, making it an ideal choice for companies with individual needs. These pioneering developments in the aviation industry clearly show that OTEC technology will play an important role in increasing efficiency and reducing costs. With its innovative approach and focus on quality, OTEC will continue to be a pioneer in the industry.

Future-proof solutions for the aviation industry

One of the biggest challenges facing the industry is the steady decline in the number of skilled workers qualified for manual processes. At the same time, the market is demanding absolute process reliability and more efficient production methods. This is where OTEC comes in with an automated and process-stable alternative to outdated systems. The trend towards digitalization and the reduction of manual work not only opens up new opportunities for customers, but also ensures long-term competitiveness.

The genesis of the state-of-the-art turbine disk processes, which were developed in close collaboration with an American OEM during the coronavirus pandemic, underlines OTEC's innovative strength and flexibility. Within twelve months, a universal and validated process was established that is now regarded as a benchmark (OM-1/26).

Contact

OTEC Präzisionsfinish GmbH

Heinrich-Hertz-Str.24

75334 Straubenhardt (Germany)

E-mail: sales@otec.de

www.otec.de

About OTEC

OTEC Präzisionsfinish GmbH was founded in 1996 in Straubenhardt near Pforzheim in Baden-Württemberg. For more than 25 years, OTEC has established itself from a start-up for polishing machines in the jewelry and watch industry to a globally active company in a wide range of industries. OTEC's finishing machines are used in many sectors such as medical technology, the pharmaceutical industry and the automotive and electrical industries.