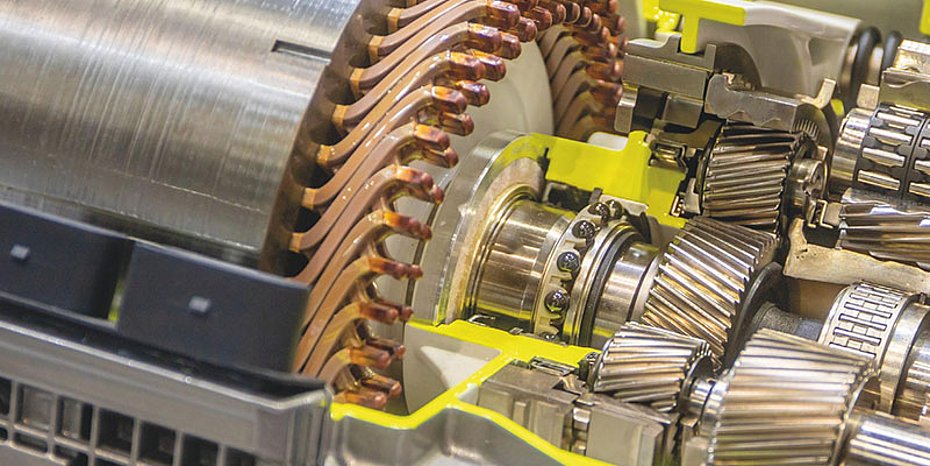

Functional reliability, cost-effectiveness and also environmentally friendly technology were the special challenges to be met when machining electric drive shafts for a well-known Polish automotive supplier. With Otec machines, optimum surface tolerances are achieved on parts for high-speed electric drives, where absolute functional reliability is essential.

Functionally relevant surface tolerances

The automotive supplier and renowned drive specialist was looking for an efficient, cost-saving and, above all, process-safe solution to optimize the surfaces of electric truck drive shafts. To ensure critical functional reliability, compliance with exact surface roughness parameters was required. The increasing demand for electric trucks causes high volumes in production and thus requires a high degree of automation in the process and handling. In addition, an optimal solution had to be found to accommodate an already tight schedule.

Perfect fit streamfinish solution

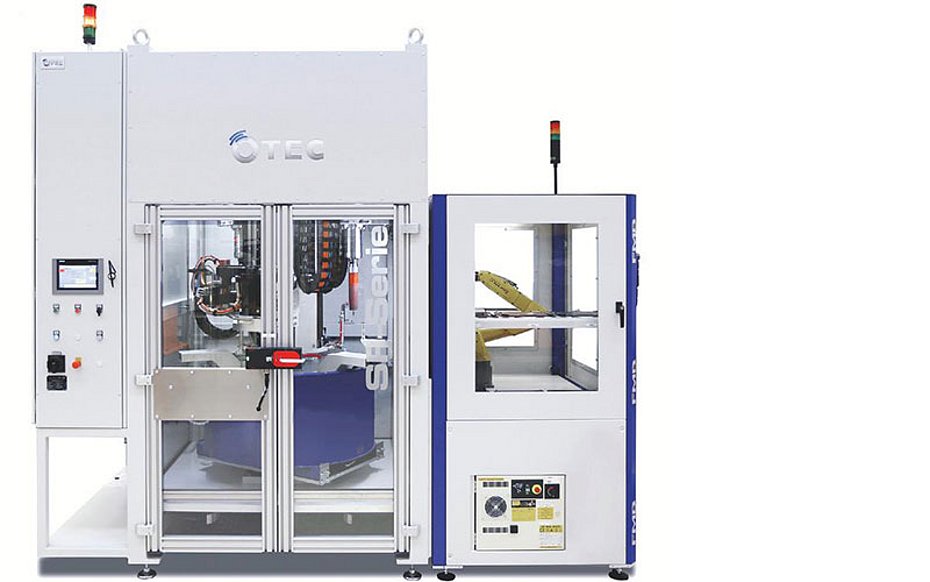

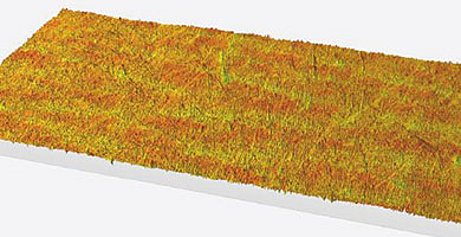

A customized machining process was developed at the Otec Finishing Center to fully meet the demanding surface requirements. In this process, the desired roughness parameters for the drive shafts were achieved using vibratory finishing technology in the so-called streamfinishing process. In SF technology, the workpieces are clamped in a holder and lowered into the rotating container filled with grinding or polishing media. The granular and abrasive process medium flows around the workpieces and ensures uniform, homogeneous removal. By adapting the processing parameters and the type of process medium used, both highly abrasive and finely polishing processes can be realized with just one machine.

Customized automation technology

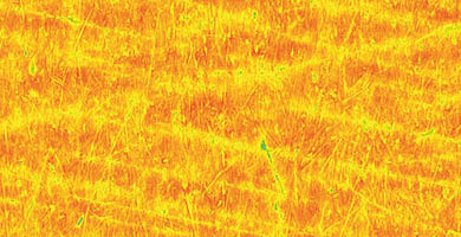

The production-ready solution for this special requirement from the e-mobility sector was achieved by means of an SF machine with three spindles, which can simultaneously machine three workpieces automatically. The advantages of Otec surface machining are: Tight tolerances of multiple surface roughness parameters are met, Isotropic surface topography, Fast machining of three workpieces in less than five minutes, Downstream shot blasting is eliminated due to the process-related introduction of residual compressive stresses, and Easy automation and integration into the production line.

Thanks to the use of a wastewater centrifuge and the corresponding circulation system, the Otec solution is environmentally friendly and conserves resources. More than 95 percent of the costs for fresh water and waste water disposal can be saved with the centrifugal water circulation system.

Flexible and competent

In order to be able to manufacture and deliver drive shafts in parallel during the time of machine set-up, the customer's production start-up was supported with an Otec-internal subcontracting. After the successful installation and testing of the streamfinishing machine, the system was fully integrated into the production process at the automotive supplier. The ongoing support from Otec process development and Otec after-sales ensures a high level of process reliability and efficient use of the system on a permanent basis.

The surface becomes the performer

The use of the Otec Streamfinish system leads to effective resource and cost savings, while at the same time achieving the desired surface roughness parameters and surface properties. The extremely high technical demands of high-speed e-drives for optimum functionality and load capacity are reliably met and the service life of the parts is significantly increased, with a simultaneous reduction in maintenance costs. The special properties of the slide-ground surface topography with its pronounced isotropy and the introduced residual compressive stresses enable excellent performance of the drive shafts.

Nicolas Petri, Otec Head of Sales Germany, says: "The rapid technical development in the automotive sector requires intensive cooperation in finding solutions to achieve a perfect result. Always being one step ahead, at the side of our customers, through permanent optimization of processes, is Otec's philosophy. The Otec Finishing Center will work out a process specifically tailored to your workpiece and application." (OM-08/23)

Contact

OTEC Präzisionsfinish GmbH

Heinrich-Hertz-Str. 24

75334 Straubenhardt-Conweiler (Germany)

Phone: +49 (0) 70 82 / 49 11 20

E-mail: info@otec.de

www.otec.de

About Otec

Otec Präzisionsfinish GmbH was founded in 1996. For more than 25 years, Otec has grown from a startup for polishing machines for the jewelry and watchmaking industry to a globally active company in a wide range of industries. Otec machine technology revolutionizes manual processing areas and makes perfect machine surface finishing possible.