Plasticizing screws for melting plastic granulate are at the heart of every injection moulding system. To ensure the highest quality and precision of its systems in this highly competitive market, the globally active Engel Austria GmbH produces the screws exclusively at its Austrian site in St. Valentin. The investment in two fully automated vibratory finishing systems from Rösler ensures more efficient production with a consistent and reproducible high quality standard. The automation concept enables virtually unmanned loading and unloading of the trough vibrators and the connected cleaning system. This pioneering development is also significant for other industries. In addition, an optimized polishing process significantly reduces the processing time.

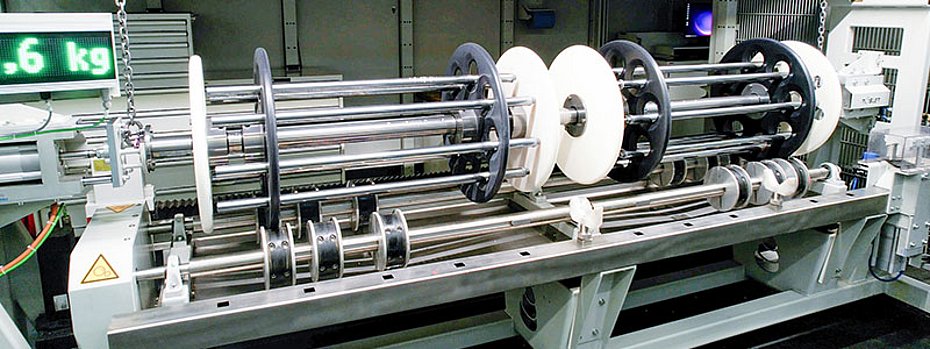

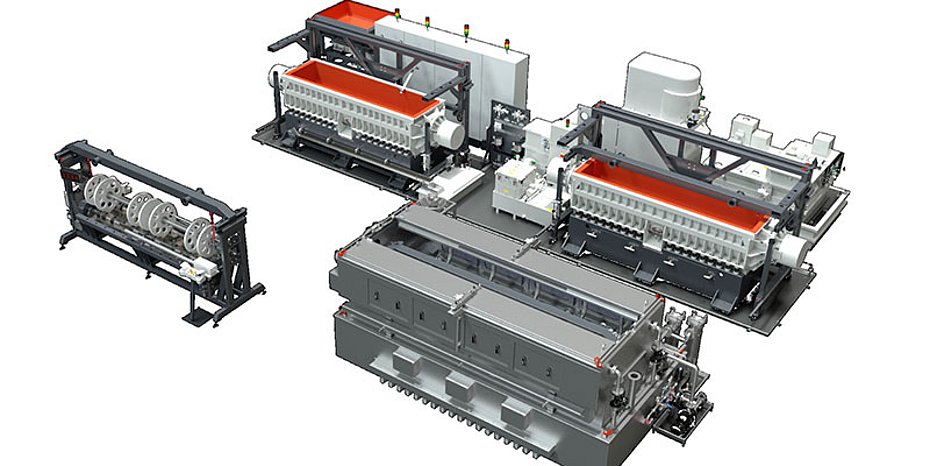

In cooperation with the Austrian automation specialist Promot, Rösler has created a system network with maximum technical networking. The workpiece fixtures, which were developed precisely for the task, ensure maximum process efficiency and component quality, while at the same time significantly reducing the system's set-up time. In addition, the capacity for polishing plasticizing screws with a length of up to three metres and diameters between 15 and 80 millimetres has been increased by expanding the system to include two trough vibrators.

Reduce handling effort and automate the loading of trough vibrators

Injection moulding machine manufacturer Engel, which has been using Rösler equipment for over 20 years, has been polishing its plasticizing screws in a single-stage process in a trough vibrator. This required a lot of manpower and time-consuming manual parts handling, especially when setting up the system. Reducing this handling effort for the employees and the automatic loading and unloading of the trough vibrators were therefore key requirements in the specifications of the project managers at Engel.

To achieve this, the gantry system from the Austrian automation company Promot, which is already used for loading the upstream grinding machines, was to be expanded. In addition, the new mass finishing system had to be designed for the throughput of plasticizing screws defined by Engel. Based on the existing polishing process with a processing time of around 8.5 hours, this would have required several trough vibrators.

Two-stage process with trough vibrators significantly reduces processing time

One focus was therefore on reducing the processing time while minimizing the number of systems required. Both are achieved by using the two-stage Keramo finishing process, which runs in parallel in two R 800/3200 TSD-15 trough vibrators. The equipment with a direct drive concept based on special unbalance motors makes the systems particularly powerful, flexible and space-saving.

Pre-grinding and fine grinding using the Keramo finishing process in the trough vibrators ensures an enormous surface improvement and reduces the roughness to a value below Ra 0.1 µm, which contributes to the high quality of the plasticizing screws. Thanks to the adapted process and the high-performance system concept, the processing time has been significantly reduced. The improved input quality of the parts also contributes to this. This is achieved through the use of fine-grinding abrasive media in the upstream grinding process, which nevertheless offer a high removal rate.

Trough vibrator loading with gantry system for fully automatic polishing and optimized set-up concept

For the automatic loading and unloading of the trough vibrators and the cleaning system, Rösler developed an automation and control concept for the gantry system in close cooperation with Promot. After grinding, it transports the plasticizing screws to the loading and set-up station. There, an employee fixes a corresponding number of screws in the holding frame, depending on their size. "This set-up process used to be extremely time-consuming because all screws had to be individually clamped on both sides. A simple insertion with floating bearing is now sufficient. This has reduced the set-up time to around 15 minutes," explains Mario Stollnberger, Head of Plasticizing. The gantry system then picks up the fully loaded part holder, transports it over the trough vibrator and lowers it there so that it is inserted into loops on the left and right. This solution allows the holder with the parts to move freely in the sanding bodies, but can be easily and automatically removed again after the specified processing time. The plasticizing screws are always fixed in and removed from the workpiece holders while parts are being processed in the systems. This further increases the efficiency of the polishing process.

In addition to the two mass finishing systems, the new polishing processing cell includes a loading station, a cleaning system specially designed by Rösler for this application and a fully automatic Z 1000 centrifuge for cleaning and treating the process water, which is reused in a closed cycle to conserve resources.

Innovative mass finishing automation concept opens up a wide range of possibilities

Trough vibrators offer almost unlimited application possibilities in mass finishing technology. However, it was previously almost impossible to automate the loading and unloading of these versatile mass finishing machines. With this innovative automation concept, Rösler has created a solution that will also ensure more efficient and faster processes in other industrial sectors such as the aviation industry (OM-10/25).

Contact

Rösler Oberflächentechnik GmbH

Vorstadt 1

96190 Untermerzbach (Germany)

Phone +49 9533 9240

www.rosler.com

About Rösler Oberflächentechnik

Rösler Oberflächentechnik GmbH has been an owner-managed company in the surface treatment sector for over 80 years. As an international market leader, it offers a comprehensive portfolio of systems, process equipment and services in the field of mass finishing and blasting technology for a wide range of industries.