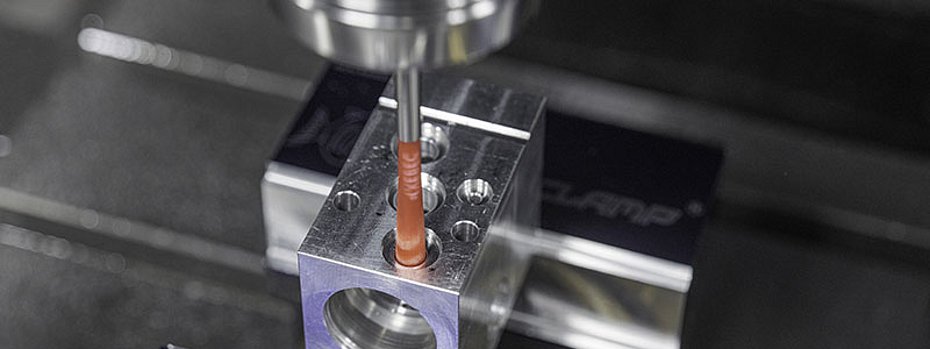

Deburring is as individual as the workpieces themselves. Different materials, processing machines, component geometries and dimensions present machining experts with a multitude of options. Selecting the most economical and technically optimal tool can be time-consuming and challenging. The 'Deburring-Guide' provides a remedy by guiding the user through a systematic selection process in just a few steps. "The tool is based on an intelligent database that links the comprehensive portfolio of deburring tools with practical application parameters," explains Steffen Hedrich, Managing Director of deburring specialist Kempf GmbH. "The user enters the specified or desired parameters for their application and receives a specific tool recommendation that is technically suitable for their requirements."

Deburring guide shows overview of recommended tool types

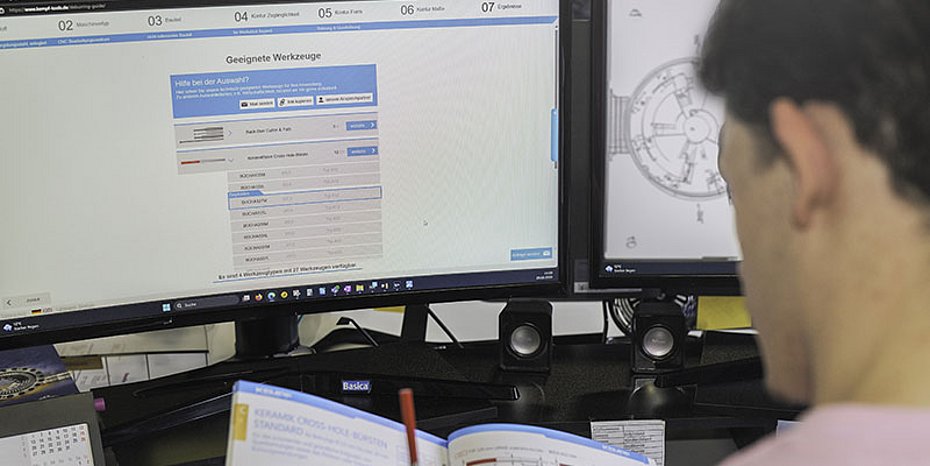

After completing the input, the user receives an overview of the recommended tool types and variants, including suitable sizes. The selection can be checked directly and viewed in the online store. Alternatively, the deburring guide offers the option of sending an inquiry to the Kempf sales team or sharing the results overview with colleagues via a link. This functionality makes the tool not only a practical tool for the individual user, but also a valuable communication instrument within teams.

Practical example of deburring inside edges

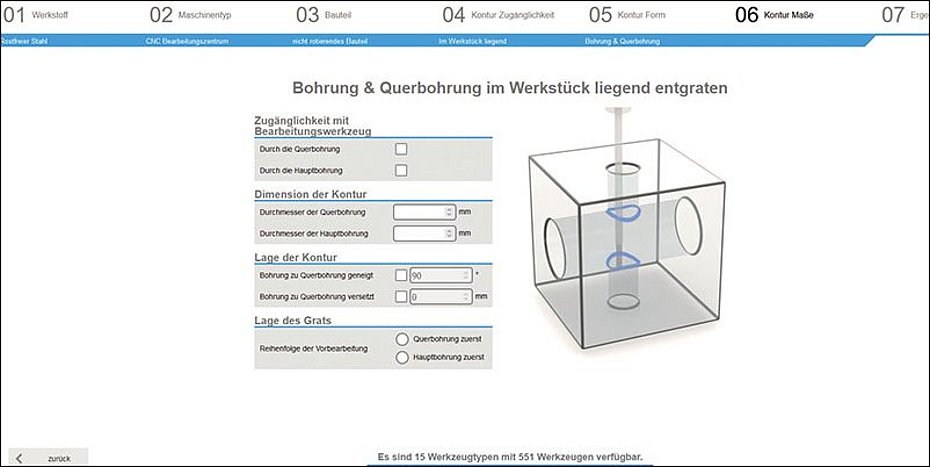

A common application in the machining industry is 'deburring the inner edges of a precise bore in a stainless steel component'. While the material (1) is stainless steel V2A/1.4301, a CNC machining center is used for machine type (2). Component (3) is a milled part with several holes and internal contours. The contour accessibility (4) shows that the inner edges of the bores are located in the workpiece and can only be reached through the larger main bore due to the clamping situation. The contour shape (5) is an intersection of the bore and cross bore. In the last step (6), the various parameters such as the diameter of the cross and main bore are shown.

Result: The deburring guide lists a total of four possible tool types as tool recommendations. The ceramic fiber cross-hole brush, which is predestined for deburring cross holes, is recommended in particular. The optimum cutting data can also be found in the catalog or on the website via the tool. The results can be sent by email or shared as a link. It is also possible to contact the deburring professionals at KEMPF directly for further assistance.

Conclusion deburring guide

The Deburring Guide is not only a practical aid, but also a platform that makes specialist knowledge and innovative technologies accessible. It combines the expertise of the largest supplier of deburring tools with the user-friendliness of modern software solutions. The intuitive operation and clear structure enable even users with little deburring experience to find a solution quickly and safely. "The deburring guide significantly reduces the complexity of tool selection," emphasizes Steffen Hedrich. "Thanks to the intelligent combination of specialist knowledge, database technology and user-friendly design, the Deburring Guide offers the machining industry an efficient and economical solution to a common problem." (OM-6/25)

Deburring guide: Six steps to the right deburring tool

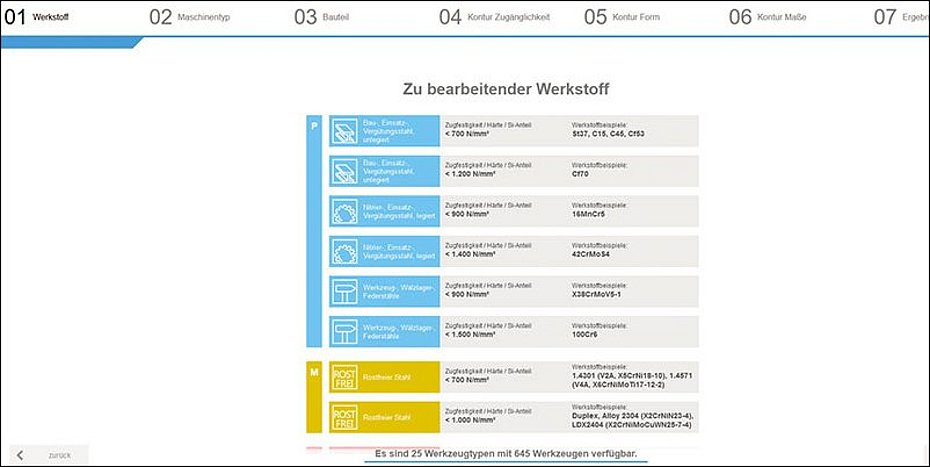

- Material selection: The first query concerns the material of the workpiece, as the nature of the material is decisive for the tool selection.

- Machine type: Here you specify whether the machining is to be carried out on a CNC machine, a manual workstation or another type of machine.

- Component selection: The type of workpiece, e.g. turned parts or milled parts, is specified.

- Contour accessibility: Is the contour easily accessible from the front, does it have to be machined from the rear, or is the contour even inside the component?

- Contour shape: Straight edges, internal contours, bores or complex free-form surfaces require different types of tools.

- Contour dimensions: Exact details of dimensions such as edge length or diameter are requested in order to further specify the selection.

Contact

Kempf GmbH

Leintelstraße 8

73262 Reichenbach (Germany)

Phone: +49 7153 95490

E-mail: team@kempf-tools.de

www.kempf-tools.de

About Kempf

Kempf has been offering innovative tools and comprehensive expertise for metal cutting for over 60 years. The company manufactures special and deburring tools, as well as PCD & CBN tools, drilling & milling tools, turning & grooving tools and roller burnishing tools. Kempf GmbH thus covers the entire field of metal cutting.