The demands placed on surfaces in medical technology are high. Not without reason, as they determine the functionality and safety of implants, sensors and other instruments - and therefore the success of medical interventions. High-quality platinum coatings can meet the specific requirements of the industry. One example of this is the Platuna PT electrolyte coatings, which have already proven themselves in technical applications. The significant increase in inquiries at Umicore MDS (Metal Deposition Solutions) indicates that this electrolyte has already established itself in this environment.

Platinum - the precious metal of choice for medical technology

The precious metal platinum impresses with its chemical inertness, corrosion resistance, biocompatibility, temperature and dimensional stability as well as its excellent electrical conductivity. Unfortunately, these properties are often only of limited use if the platinum coating is inadequate - the quality of the coating is crucial to maintaining the relevant board properties and therefore the performance of the end product.

Platinum electrolyte Platuna PT sets new standards

Platuna PT is a highly developed, pure platinum electrolyte specially designed for technical applications. It is based on a strongly acidic solution with a comparatively low sulphuric acid content. This makes it less aggressive towards the substrate to be coated and enables easier application on sensitive or supposedly non-activatable materials. For example, direct deposition on niobium, which is frequently used in medical technology, is also possible. Deposition takes place at a speed of around 0.13 µm/min at 5 A/dm² - regardless of the current density. This property enables a uniform layer distribution, even with complex geometries. This is an advantage in the manufacture of miniaturized components.

The deposited layers consist of 99.9 percent platinum, are high-gloss, crack-free and have a density of 21.4 g/cm³. The hardness is around 350 HV. Together with the low-reaction behavior of platinum towards other materials, this makes the layers very resistant and enables a long service life (possibly also in the human body). The achievable layer thickness of up to 50 µm - an exceptional value in electrolytic processes - also allows certain freedoms with regard to partial differences in thickness and the integration of microstructures in addition to the extended durability.

High-quality platinum surface in practice

Platina PT proves useful in a wide range of medical technology applications:

- For example, in sensors for pH, glucose, oxygen or ECG measurement, a coated, smooth and non-porous surface improves the signal quality. In addition, the high electrical conductivity and chemical inertness ensure reliable measurement results even in long-term applications in the body.

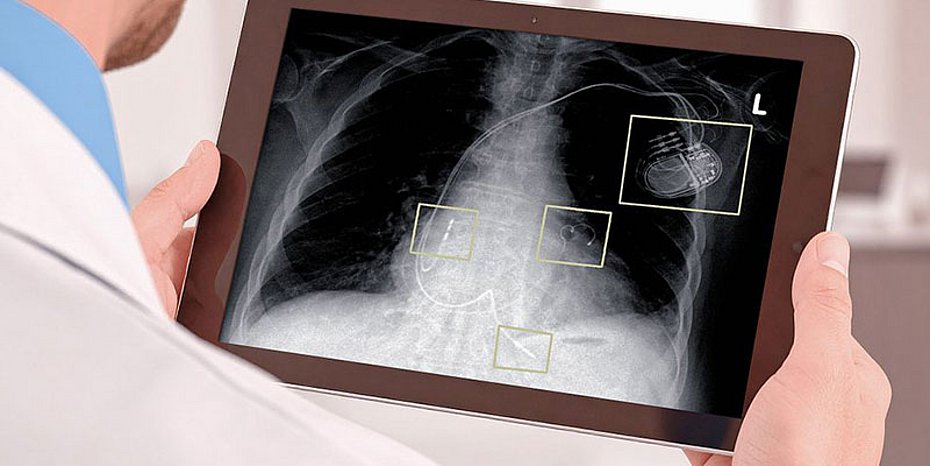

- Coated implants for pacemakers or neurostimulators have long-lasting electrical contacts, for example for controlling electrical impulse transmission, as well as biocompatibility.

- In catheter technology, platinum markers are used to enable precise positioning of catheters under X-ray control. There are also electrodes in ablation catheters or stimulation systems, which benefit from the high conductivity and corrosion resistance of the coating.

- Thanks to the coating, connecting elements in medical devices have a stable, corrosion-resistant contact surface with low contact resistance. This means that they are not affected by frequent plugging or sterile conditions.

- In laboratory and analysis technology, coated electrodes for measuring systems or microfluidic sensors enable precise and reproducible electrochemical measurements.

- Coated surgical instruments guarantee the highest possible dimensional stability and are therefore ideally suited for technically demanding and precise applications. Their smooth, high-gloss finish also makes them easier to clean and sterilize.

Reliable handling

Another argument in favor of Platuna PT is its simple and reliable handling. "The electrolyte is extremely durable, does not precipitate and can be transported and stored without any problems - even without refrigeration," explains Martin Stegmaier, head of the relevant department. This is an advantage of the electrolyte that is particularly important for production companies. This is because larger storage quantities are possible, which allows a forward-looking cost calculation - especially for series production over a longer period of time. (OM-8/25)

Contact

Umicore Galvanotechnik GmbH

Klarenbergstraße 53 - 79

73525 Schwäbisch Gmünd (Germany)

Phone: +49 (0) 7171 607 - 01

E-mail: galvano@eu.umicore.com

mds.umicore.com

About Umicore Metal Deposition Solutions

The Umicore Business Unit Metal Deposition Solutions (MDS) is the business center within the Umicore Group for the two established business units Electroplating and Thin Film Products. Metal Deposition Solutions is one of the world's leading suppliers of products for the (precious) metal-based coating of surfaces in the nano and micrometer range - with the expertise of the two business units, the company combines the two highest quality processes: Electroplating and PVD coatings.