The German government wants to see at least seven to ten million electric vehicles on Germany's roads by 2030. This is another reason why electromobility is to be massively expanded in Germany. The group led by Prof. Dr. Timo Sörgel from the Center for Electrochemical Surface Technology (ZEO) at Aalen University is researching processes that could enable the production of improved battery components that are more cost-effective, environmentally friendly and safer. In terms of electric cars, this would mean faster charging times and higher performance. After all, this also increases acceptance of electric vehicles among drivers. In addition, it would be much easier to recover the raw materials from the electrodes, making the batteries more sustainable and economical.

Research group works on composite electroforming

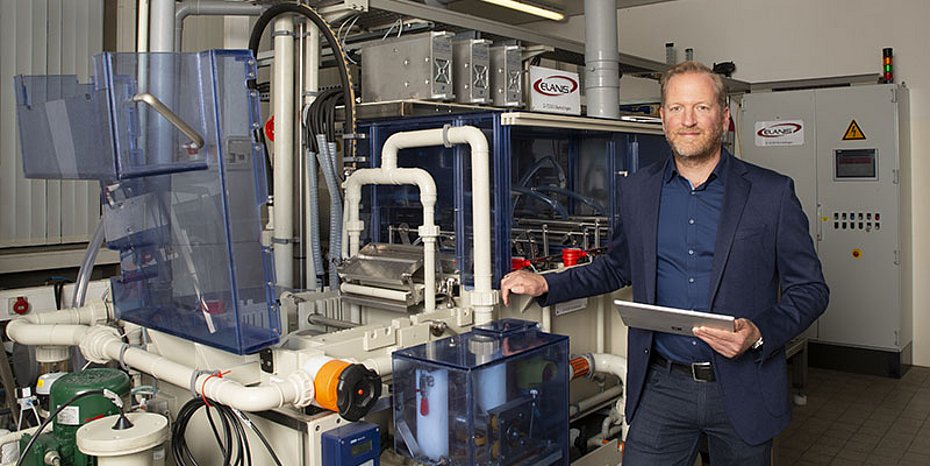

Sörgel has been working for around ten years on electroplating processes in which metals are deposited on a surface by means of an electric current. The aim is to optimize electrodes for lithium batteries: "The process we have developed is called composite electroforming. In this process, we combine dispersion deposition and foil electroforming to produce cathodes for lithium-sulfur and lithium-ion batteries." In classic foil electroforming, a rotating roller, for example made of titanium, is electroplated, and the deposited metal layer is simultaneously and continuously removed from this roller again in the form of a foil. During dispersion deposition, functional particles, in this case the cathode active materials, are also incorporated into the electrodeposited metal matrix.

"This combination of processes thus gives us a free-standing composite film that can be used directly as a finished battery cathode. We recently commissioned the world's first pilot plant for this here in Aalen," says the researcher, not without pride. Since 2019, this technology and the film composite material produced by his team have been patented in Germany, France and Great Britain. Sörgel's research group includes many young students who are enthusiastic about the future technology of composite electroforming.

Students research surface technologies

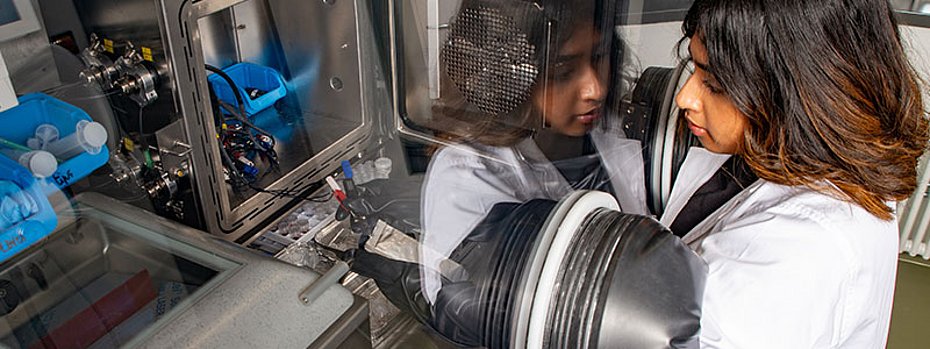

The team also includes student Suvetha Logeswaran from the Surface Technology / New Materials course. In her bachelor's thesis, she is investigating the compatibility between electrodeposited metal matrix and the incorporated functional particles during dispersion deposition as a function of surface and interfacial energies. "I came to surface engineering through my chemistry studies. I'm excited about how innovative and current our topics are, for example battery technology." She particularly likes the hands-on mentality in the research group. Spontaneous ideas are implemented without further ado, and when problems arise, for example with 3D printing or CAD designs, solutions are quickly found within the team. "In the research group, I noticed how practical my studies at Aalen University were. I was able to practically apply knowledge from the lectures here in the lab," says Logeswaran.

Phillip Scherzl, who completed a dual study program at Aalen University supported by Schott, also gained plenty of practical experience. In the "Advanced Material and Manufacturing" research master's program at Aalen University, he was able to combine the areas that particularly interested him: electrochemistry, electroplating and battery technology. "In my thesis, I worked on fundamental issues in order to be able to later implement composite electroforming of cathodes for lithium-ion batteries with aluminum as the matrix metal." This led to the development of a defined structured current collector made of aluminum for batteries - important results that contributed significantly to a recent scientific publication by the research group. After completing his studies, he joined the company as a Process Engineer Surface Technology: "Since I worked very independently and took on responsibility throughout my master's degree, this is now easy for me when starting my job."

New talent for battery research

Recruit promising talent directly from universities that have already gained experience in relevant projects: Companies that work closely with academia benefit from this. This is especially true for highly application-oriented and future-oriented areas such as battery research. After all, the global market for batteries is growing rapidly: According to a study by McKinsey, demand will increase by 30 percent annually until 2030. At the same time, raw materials for manufacturing will become scarce in the long term - so new generations of batteries that do not require rare earths and can be recycled efficiently are urgently needed. "The training of experts in the battery sector, as it works in cooperation between scientific institutions and companies, is thus an essential building block for the success of the energy transition," emphasizes Sörgel. (OM-10/23)

Contact

Aalen University of Applied Sciences

Technology and Economics

Beethovenstraße 1

73430 Aalen (Germany)

Phone: +49 7361 576-0

E-mail: info@hs-aalen.de

www.hs-aalen.de

About Aalen University

Five faculties, 60 versatile and forward-looking study programs, more than 130 cooperations worldwide and over 5,000 students: Aalen University of Applied Sciences is one of the largest universities of applied sciences in Baden-Württemberg. It occupies top positions in research and teaching in the state and throughout Germany.