Benseler uses two different processes to coat plastic parts for the locker lock manufacturer Burg and the exclusive speed pedelec pioneer Stromer: While the high-quality PVD process is used for Burg, Benseler uses a precisely coordinated wet coating process for Stromer. Both applications are examples of how expertise from the automotive industry can be transferred across sectors - to sophisticated components with high design standards.

Physical vapor deposition for design elements

PVD (Physical Vapor Deposition) is a vacuum-based coating process in which the starting material is converted into the gas phase using physical processes and then deposited on the component in thin layers of between 3 and 350 nm. The technology is suitable for plastics as well as glass, aluminum and metallic components and is mainly used in the automotive industry as a replacement for electroplating. However, the surface specialists at Benseler also use the process specifically for exclusive design elements - for example for high-quality office furniture or operating elements with additional functions.

Color fidelity and robustness for Speed Pedelecs with wet painting

For the Swiss speed pedelec manufacturer Stromer, Benseler is carrying out the wet painting of the side battery box flap. This flap is a key design element of the high-quality S-pedelecs, but must be particularly robust, as stone chips, dirt and splash water are unavoidable. At the same time, its color must exactly match that of the frame - across the entire color range of the exclusive S-Pedelec editions. In order to meet these high design and functionality requirements, the polyamide (PA) flap undergoes a sophisticated pre-treatment and coating process at Benseler, as well as a multi-layer wet paint finish. The color fidelity of all parts is matched using an optical light measuring device based on a master sample. With this solution, Benseler contributes to the aesthetics of the S-Pedelecs while maintaining the highest quality standards.

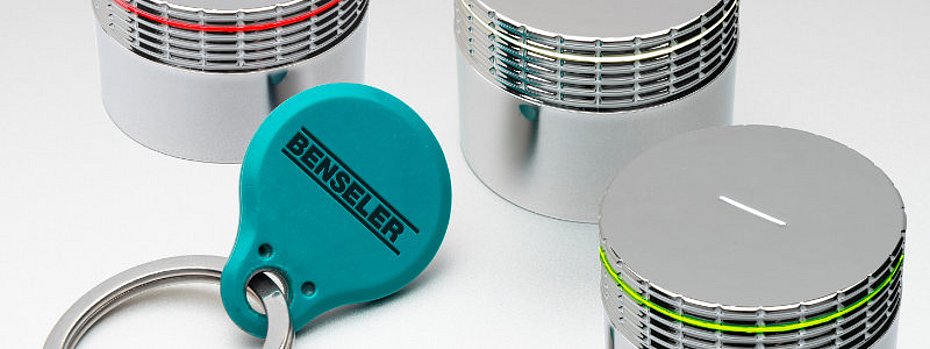

Locker lock with PVD coating

Another example of the versatile use of PVD coatings are the knob cabinet locks from Burg for the designer furniture manufacturer USM with integrated Bluetooth chip and light signal. A green or red illuminated ring indicates to the user whether the lock is locked or open. The PVD coating not only ensures an attractive chrome look in a high-quality office furniture collection, but is also crucial for the functionality of the lock: in addition to the transparency of the coating for the integrated light signal, its permeability for the Bluetooth wave spectrum is also required. In addition, it should ensure a high-quality appearance in two color variants, which even hand perspiration and skin creams do not harm and which is reliably protected against scratches and abrasion.

To achieve this, the polycarbonate (PC) components are first extensively pre-treated. This is followed by priming with wet paint using a spray process and application of the chrome colors as a PVD layer. The light ring is then removed by milling off the PVD coating to create the necessary transparency for the light signal. Only then is a scratch-resistant clear coat applied in the finishing process. As a result, the combination of processes offers high durability and a very high-quality visual appearance. Here too, absolute color consistency has top priority, as the cabinet system itself also has metal components that the locks have to match. Benseler ensures the desired Bluetooth functionality not least thanks to its expertise in the demanding automotive industry, where PVD coating is a popular process for radar and lidar applications (OM-11/25).

Contact

Benseler Holding GmbH & Co. KG

Zeppelinstraße 28

71706 Markgröningen (Germany)

E-mail: info@benseler.de

www.benseler.de

About Benseler

Benseler is a service provider and partner for technically sophisticated solutions in the areas of coating, surface finishing, deburring and electrochemical metalworking of series parts. The Benseler Group, based in Markgröningen near Stuttgart, consists of two divisions: Coatings and Deburring.