Per- and polyfluorinated alkyl compounds (PFAS) continue to be the subject of controversial public debate. Many are vehemently calling for extensive bans on these perpetual chemicals, while others are not so keen on the idea. The coatings industry would also be severely affected by restrictions. For this reason, the coater APO has developed a PFAS-free high-performance bonded coating together with a paint manufacturer, which replaces current PTFE coatings. Sealing technology in particular benefits from the new solution.

Development of PFAS-free bonded coating for elastomer seals

"Many of the paints and coating systems available contain some form of perfluorinated or polyfluorinated alkyl compounds. We in the painting and coating technology sector would therefore naturally be severely affected by a ban," says Antonio Pozo, Managing Director of APO GmbH Massenkleinteilbeschichtung, describing the situation in his industry. As was the case six years ago, when the co-solvent N-methyl pyrrolidone (NMP) was banned from water-based paints due to REACH regulations, PFAS is another important chemical in the coatings industry that is under scrutiny. However, as the service provider is constantly working on removing critical substances from its portfolio and replacing them with harmless substances, it is also reacting very quickly in this case. After initial discussions about the environmental impact and potential health hazards posed by PFAS, the company developed a PFAS-free bonded coating for elastomer seals together with a coating manufacturer. This is because current bonded coatings that can cope with the harsh operating conditions in sealing applications generally contain polytetrafluoroethylene (PTFE), a widely used polymer from the PFAS group. It can withstand high chemical and thermal loads and has excellent sliding properties. From a sealing technology perspective, PTFE coatings have therefore rightly been regarded as the epitome of performance. The standard for a PFAS-free alternative is correspondingly high.

High demands on wafer-thin layers

Functional coatings are subject to high stresses, particularly in the sealing sector. In addition to the mechanical, thermal and chemical stresses, there are two details that pose a particular challenge for bonded coatings. Firstly, elastomers are difficult to wet due to their low surface energy and even the best bonded coatings do not adhere adequately to their surfaces without professional pre-treatment. Secondly, elastomer seals, such as O-rings, are often stretched considerably during assembly. This is a process that even the wafer-thin sliding layers have to withstand. The developers therefore built on a particularly elastic, NMP-free PTFE high-performance bonded coating, which already has a broad chemical base, is very easy to process and adheres excellently to elastomers.

However, despite this promising basis, the path to a PFAS-free premium coating remained challenging. "In fact, it is not possible to replace PTFE one-to-one with another solid lubricant without adapting the entire coating system," explains Pozo. One of the reasons for this lies in the complexity of rubber friction, which is significantly influenced by the viscoelastic material properties of elastomers. In relation to rubber, classic friction laws lose their validity, whereas application parameters, adhesion and deformation forces play a greater role. Therefore, each application brings with it a special friction problem and the functional layer must be correspondingly adaptable. Consequently, the experts focused on several components of the coating mixture in addition to PTFE. In addition to NMP and PFAS, they also dispensed with additives containing silicone. Several development and test cycles were necessary to determine the most promising bonded coating candidate for the final, extremely comprehensive comparison and suitability study.

New bonded coating put through its paces

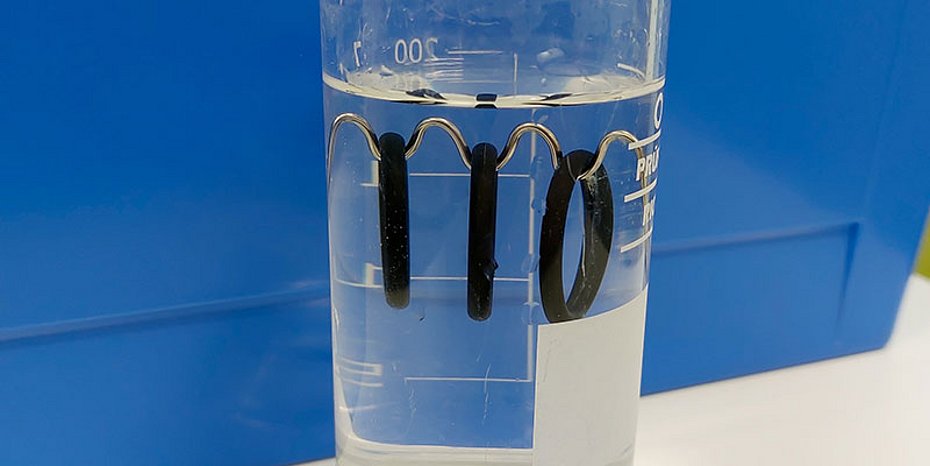

First, standard O-rings made from the most important sealing materials were coated under series conditions, i.e. by machine and in large quantities, the processability was evaluated and the bond with the elastomer surfaces was tested. Particular attention was paid to silicone materials, as these are generally extremely difficult to coat. However, the surface adhesion of the new coating exceeded that of the best comparable coatings to date, even on silicone. As it was important that the test conditions were close to the application and usual for sealing technology, the team sent the parts to a well-known elastomer institute for further analysis after initial internal stress tests. There, analysts tested the coated parts according to relevant test standards and compared them with the basic bonded coating and three competitor coatings of the latest generation. All comparison coatings were also NMP-free, but contained PTFE. As is usual for elastomers in the sealing sector, the test specimens underwent hot air ageing and a cold bending test and were stored in distilled water, reference oils and fuel. The subsequent expansion allowed the quality of the functional layers to be assessed. Exclusion criteria were cracks, bulges and detachment from the surface. Finally, the external sealing assembly of the O-rings was simulated and the maximum press-in forces were recorded.

Impressive results across the board

Pilot customers were also involved during development and carried out their own studies with coated components. "Of course, we are rarely allowed to look behind the scenes at customers," Pozo clarifies. But the results convinced even the biggest doubters. When new, the thin layer can be stretched by up to 100 % without hesitation, without tearing or flaking off the surface. It is well equipped chemically and thermally, because even after exposure to different media, it continues to withstand elongation of up to 100 % and neither high temperatures of up to 200 °C nor cold temperatures of down to - 40 °C cause any damage. However, the PFAS-free coating is particularly impressive in action. In assembly tests with 3.53 mm thick O-rings, the wafer-thin sliding layer reduced the maximum press-in forces by up to 90 %, even after repeated installation, thus achieving better values than all comparable coatings. The performance of the coating remains constant even with repeated, reciprocating loads and it ensures that the components slide evenly with little effort. Both the colorless-transparent version with UV indicator and the colored versions are based on the same coating system, which simplifies the approval process in companies from case to case. This means that the new PFAS-free bonded coating has already taken its place in sealing technology. This is because it benefits from the new solution, regardless of what PFAS restrictions the future holds in store. (OM-6/25)

Contact

APO GmbH

Konrad-Zuse-Straße 2b

52477 Alsdorf (Germany)

Phone: +49 2404 59980

E-mail: info@apo.ac

apo.ac/massenkleinteilbeschichtung

About APO

Founded in 2002, APO GmbH has comprised two business divisions since 2010: APO GmbH Massenkleinteilbeschichtung - with the APO LABS-frei cleaning service for small parts - and APO GmbH Industrielackierung Both are based at the company's 8,000 m² site in Alsdorf. The state-of-the-art machinery is spread across two halls with a total production area of 1,600 m².