The only plastic bottle to date that combines highly effective product protection with 100% unmixed recyclability: this is thanks to a revolutionary coating technology that KHS GmbH brought to market maturity around 20 years ago. It took some convincing before the beverage industry jumped on the bandwagon in the wake of increasing sustainability efforts and the demand for recyclable packaging. The effort has paid off: a large number of national and international bottlers now rely on the technology, meaning that the system provider has increased its capacity at the Hamburg site in order to meet the growing demand.

Behind this success story is the idea of applying a wafer-thin, chemically pure layer of glass to the inside of PET bottles to protect them from oxygen ingress and CO2 loss. This preserves the taste and extends the shelf life - similar to a glass bottle, but with the lower weight and greater robustness of a plastic bottle.

Food suitability proven

The concept of barrier technology is not new. However, the competition uses blended or multilayer materials that make subsequent bottle-to-bottle recycling into pure PET recyclate difficult or impossible: The composite materials can hardly be separated from each other and form a jumble of secondary raw materials and chemical compounds. This is not the case with the FreshSafe PET coating system from KHS: here, the inner coating can be completely washed off during the recycling process, allowing 100% bottle-to-bottle recycling. This has been confirmed by both the EPBP (European PET Bottle Platform) and the US APR (Association of Plastic Recyclers). In addition, food suitability has also been officially verified by the US FDA (Food and Drug Administration) and most recently by the Safety Certification of the Chinese National Health Commission.

Over the years, KHS has continuously improved the new technology and has now taken it to the next level with its latest development. The two most important goals here were to increase performance on the one hand and efficiency on the other.

Alternative performance classes

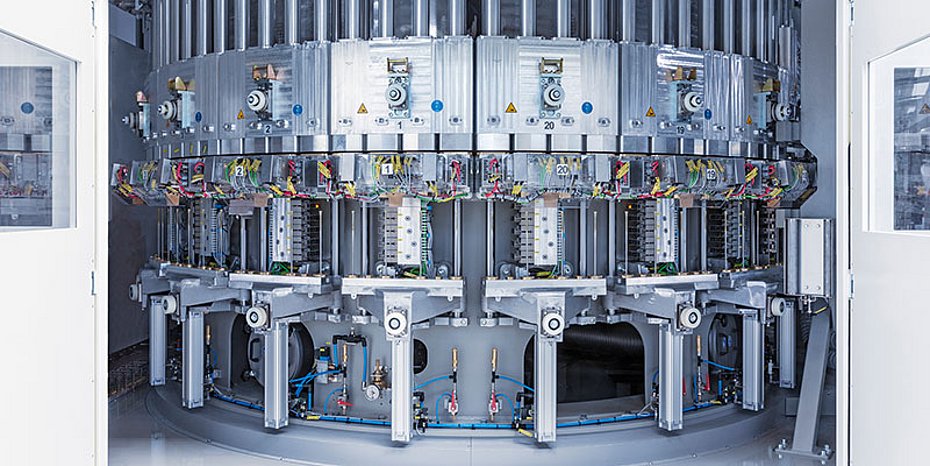

Thanks to the enhanced machine generation, which replaces the previous 20Q and 20L series, the InnoPET Plasmax 80ES version can now coat PET bottles at a speed of up to 48,000 bottles per hour. The very first Plasmax machine of the latest generation is located at the German mineral water bottler Vilsa.

The process improvements implemented by the KHS experts are responsible for the increase in output. Within the FreshSafe PET TriBlock system, for example, the infeed and discharge of the coating machine has been brought to the same height as the stretch blow molder and filler. This eliminates the need for the lifting wheel, which previously had to transport the containers 30 centimetres upwards to the coating module. Bottle handling has also been simplified and made even more robust - all in preparation for even higher speeds, which Philipp Langhammer, Product Manager Barrier Technology at KHS, promises. "With our foray into higher performance classes we want to reach the large bottlers of carbonated soft drinks in particular, who need to protect their beverages fromCO2 loss, especially in smaller bottles," says Langhammer. "After all, the smaller the container volume, the larger the surface area. And the risk of carbon dioxide diffusing out or oxygen diffusing in through the plastic wall increases accordingly."

Individual customer requirements

The modular machine platform can be configured for very different speeds according to individual customer requirements. The InnoPET Plasmax 48ER will be available from the beginning of 2025 especially for niche suppliers, smaller bottlers or converters who are more interested in a low to medium capacity range: it can coat up to 24,000 bottles per hour.

In addition to different performance classes, particular emphasis has been placed on greater flexibility: For example, KHS has equipped the block system with a bypass wheel for newcomers who offer sensitive products as well as those that do not require additional product protection. This ensures that the corresponding bottles are transferred directly from the stretch blow molder to the filler, bypassing the coating module.

Higher evacuation capacity

In terms of the coating process itself, the further development scores particularly well with its increased evacuation capacity: it reduces the requirement for the vacuum stability of the containers. As a result, PET can be saved as part of lightweighting: "A customer who previously needed a 22 gram PET bottle for a shelf life of 100 days can reduce the weight to just 14 grams thanks to the latest FreshSafe PET coating technology - and double the shelf life at the same time," Langhammer calculates. "For beverage bottlers who have to pre-produce products for the peak season, this has two advantages: Firstly, they can save up to a third on plastic, and secondly, fewer drinks have to be thrown away because their best-before date has expired."

Further increased efficiency

In terms of increasing efficiency, decisive optimizations have also been made. "The most important innovations here are the creation of a common modular platform and the reduction in the complexity of parts, components and maintenance tasks," says Langhammer. "For example, the highest possible number of identical parts is used for different performance ranges."

An improved and more flexible layout of the new InnoPET Plasmax machine generation also makes it easier to integrate the block into the production area thanks to a smaller footprint: the machine depth has been reduced by 25% and the stretch blow molder, coating module and filler can be positioned in an L-, U- or V-shaped layout in the filling hall, depending on the space available.

Reduced maintenance costs

In addition to higher output, even better coating quality and more flexibility, the new series offers beverage producers a tangible economic advantage in terms of operating costs: "We have succeeded in reducing maintenance costs," explains Langhammer. "This is of course an important criterion when deciding on our systems." The improvements based on proven technology include simplified access to all process gas valves. The redesign of the lance carrier system saves on pistons, thus reducing the number of seals and consequently the service effort and costs. Finally, a new type of vacuum pump reduces costs. "By further improving the service life of our maintenance parts, we can extend the maintenance intervals," says Langhammer happily. (OM-4/24)

What significance does sustainability have for Vilsa?

As a mineral spring, we owe a lot to nature and would like to give something back in return. The sustainable protection of our springs is therefore a fundamental concern for us. Our organic mineral water certification and our commitment to developing science-based climate targets in accordance with the net zero standard of the Science-Based Targets Initiative (SBTi) ensure that we comply with the strictest limits and highest industry-specific sustainability standards in the German market.

Why do you use Plasmax barrier technology for your mineral water?

Our consumers rely on VILSA to provide them with a naturally pure premium product. To live up to this claim, we have to effectively protect our precious product from external influences and reliably safeguard its taste. That's why we rely on packaging that combines the highest sustainability standards with the best possible product protection.

To what extent does Plasmax also convince you in terms of sustainability?

All of our disposable bottles are made from 100% recycled and recyclable PET. It is therefore only logical for us to rely on barrier technology for our product protection, which not only offers the best protective properties, but also continues to enable 100% unmixed recycling.

Henning Rodekohr is managing partner of the Vilsa Group, which is the first German mineral water bottler to rely on innovative product protection from KHS. The very first InnoPET FreshSafe block of the latest Plasmax generation is installed at the bottling plant in Bruchhausen-Vilsen, Lower Saxony.

Contact

KHS GmbH

Juchostr. 20

44143 Dortmund (Germany)

Phone: +49 231 5690

E-mail: webmaster@khs.com

www.khs.com

About KHS

The KHS Group is one of the world's leading manufacturers of filling and packaging systems in the beverage and liquid food sectors. In addition to the parent company (KHS GmbH), the group of companies includes various foreign subsidiaries. At its headquarters in Dortmund and in its other plants, KHS manufactures modern filling and packaging systems for the high-performance sector.