V-Zug is the leading Swiss brand for household appliances. For over 100 years, V-Zug AG has been developing and producing household appliances for the kitchen and washroom at its main production site in Zug, Switzerland, and, since 2013, also in the area of refrigeration appliances in Arbon and now in Sulgen, Switzerland. In Zug, everything is produced in-house - from the sheet metal to the finished product. In line with the premium claim, the oven, steamer dishwasher, washing machine and tumble dryer are in the upper price segment. Quality and functionality are given high priority in all products. In order to further develop this standard, the company invested in a new powder enamelling system. "We chose Asis because they credibly demonstrated in the run-up to the project that they could build and project manage such a plant," says Roland Häfliger, Project Manager Parts Production & Surface Technology V-Zug. "Asis was also one of the few suppliers that offered to be the general contractor for the entire plant."

New coating center

The V in the company name V-Zug still comes from the founding days as a galvanizing plant, since then the town on the picturesque Lake Zug has developed around the company. Due to the limited space available, production can only grow upwards. The plan is to produce twice as much in the future on almost half the space. All plant components of the approx. 1,400 m² coating center have been designed to fit into the second floor of a modern wooden building. The renewable raw material wood is not only sustainable, it also creates a pleasant atmosphere in the so-called Zephyr Hangar, which is unusually positive compared to other industrial production halls. 40-50 different components can be coated automatically from batch size 1. The range includes four basic types of baking cases and various flat goods, such as hot-air or baking trays.

Automatic task

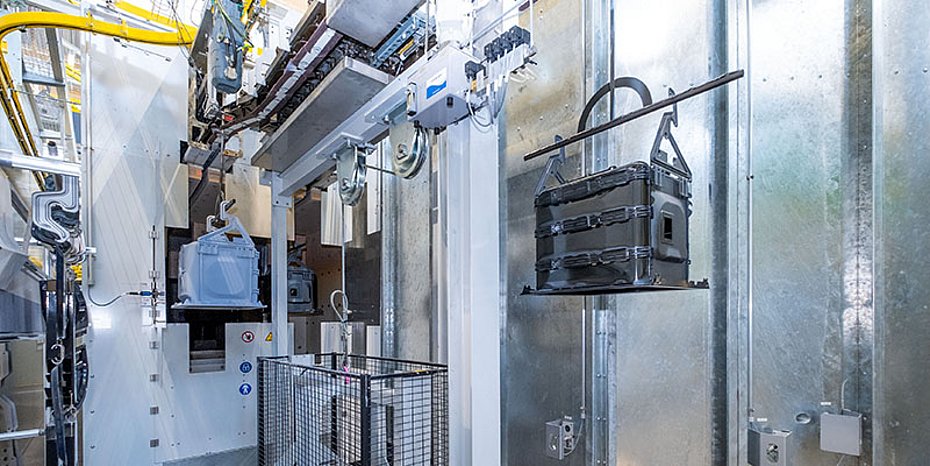

The baking boxes come out of the welding line every 50 seconds and are automatically transferred to a flat conveyor belt. Their first station is the ironing and clipping line. Clips are automatically attached there. These cover certain areas to protect them from the enamel powder so that they remain coating-free for further processing. Retaining clips are then automatically attached and transferred to the Power & Free conveyor system by a transfer robot. The flat goods are fed in at a separate manual station.

Pretreatment for optimum coating quality

At the 5-zone spray pretreatment, all parts are freed from drawing oil and dirt for optimum coating quality. The spray pumps of the two-lane system are not controlled via butterfly valves as usual, but via frequency converters. This enables consistent integration into the PLC system control, and the most favorable operating state in each case, such as pause switching, can be set. The spray pressure is kept constant via electronic pressure pipe monitoring. Special attention has been paid to economical rinsing agent consumption with cascade control. After the blow-off zone, the workpieces are dried in the adhesive water dryer above so that no water remains on the surface.

Application combination

All powder jobs take place in an air-conditioned housing. The baking cases and the flat goods are coated in a total of three powder booths. Asis' experience in the household appliance industry has shown that the combination of robots and linear axes is an ideal setup. Here, the economical linear axes coat the vertical, flat surfaces, while the robots powder edges and interior areas. Two booths handle the basic powder application, while the third powder booth is for the special coating of steam cookers. Sensors detect which part is currently entering and the parameters and programs are optimally set accordingly.

High requirements

"V-Zug's requirements were very high right from the start, and a lot of emphasis was placed on automation and digitization," recalls Dietmar Binder, Project Management and Sales Asis. "One challenge was that we wanted to run through the plant with only one conveyor technology system, the Power & Free conveyor, and only one uniform wagon train and hangers." This makes sense, of course, as the overall process is simplified and no additional sorting functions are needed in the plant. This was implemented with a hanger robot and a hanger cleaning system designed by Asis. The transfer robot removes all workpieces from the hangers, which are also wetted with powder during application. In the meantime, these are cleaned in the hanger cleaning system and the robot can then transfer the workpieces to the same cleaned hanger, which then travels to the enamel baking oven.

The enamel powder is baked in at a temperature of 850 °C. The specially built shingled plate conveyor drags the Power & Free conveyor's car trains with the car trains hanging from them through the oven undamaged and then returns them. The flexible scales close off the top of the oven at all times so that no energy is lost and at the same time protect the wagon trains above as well as the conveyor chain, which are not designed for these temperatures. The still-hot baking boxes that are moving out radiate their energy onto the workpieces moving in. There are nine firing zones with different temperatures in the oven, which are heated by 16 burners. At present, the baking oven is still operated with natural gas, but a conversion to hydrogen is being prepared. Shiny black, like Swiss dark chocolate, the workpieces leave the oven and line up in the empty drawing buffer to cool down further.

One could almost think that they are now ready for assembly. Some parts are further refined according to the customer's wishes. In another booth, a permanent non-stick coating is applied by means of a robot and then dried in a convection dryer at 250 °C. The coating is then applied to the parts.

Digitization and sustainability

"We chose Asis because we attach great importance to functionality and quality, which includes the complete traceability of quality data during the processes," says Roland Häfliger. This is made possible by the Surface-Analytics 4.0 software. All process data of the plant is recorded in a central data storage. The user accesses it via smartphone, tablet or laptop. In addition to important key figures and reports for optimizing plant performance, each individual part can also be fully traced.

A few components that do not meet the high quality requirements in the first step are subsequently brought up to top level in the rework booth. Naturally, everything is recorded transparently and traceably via touch panel. Reworking instead of throwing away - this is also sustainability in the production process.

Precise plant preplanning

The entire plant was set up digitally in advance. In addition to classic reachability studies, the robots were of course also simulated and their programs created offline. The robot simulation of all individual stations and the entire material flow in the plant were linked in an overall simulation. The different process times of the stations were taken into account. This made it possible to make precise predictions about the design of the conveyor system with buffer sections, sources of error in the individual areas, zones working in parallel and the expected throughput.

"The highlight of the plant is difficult to determine, namely it is the plant as a whole," Roland Häfliger sums up. "The entire plant in its functionality is unique." Each individual process was precisely coordinated, automated and linked with uniform control technology like Swiss clockwork. German engineering meets Swiss precision - customer-oriented preliminary planning, robotics expertise and the use of digital solutions resulted in the world's most modern enameling plant in Switzerland. (OM-05/23)

Contact

ASIS GmbH

Kiem-Pauli-Straße 3

84036 Landshut (Germany)

Phone: +49 871 27676-0

E-mail: mail@asis-gmbh.de

www.asis-gmbh.de

About Asis

Asis GmbH solves special tasks in automated surface technology. The internationally positioned system provider exports from four locations in Germany and a subsidiary near Shanghai to over 30 countries worldwide. The range of services includes turnkey solutions in the field of coating, application technology, quality assurance, surface treatment, electron treatment, process automation technology and digital simulation.