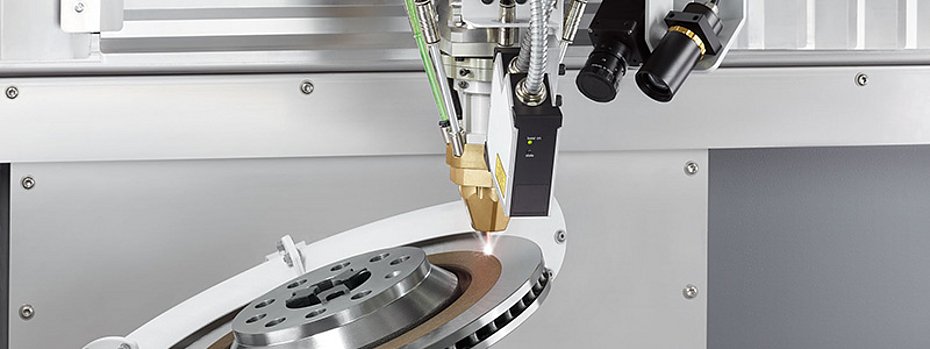

How does the protective coating get onto the brake disc faster and better? How does it stay on longer? "The solution is intelligent coatings, such as those we can apply with our AM Coating system," says Dr. Géza Koscsák. The new Head of Additive Manufacturing at the Chiron Group since October 2022, in his previous position as Head of Predevelopment he played a key role in the development of the new system and the decision in favor of the high-speed buildup welding process.

Innovative and productive high-speed laser buildup welding process

In high-speed laser buildup welding, the powder particles travel a longer distance to the deposition point than in conventional LMD processes. This means that they can absorb more energy and already melt in the laser beam, which allows a significantly higher coating speed. The process also has a clear advantage over thermal coating with high-speed flame spraying: there is no need to pretreat the brake discs, and the process is significantly shorter. According to Dr. Koscsák, the higher speed and shorter process are two arguments with which AM Coating scores points with regard to the future Euro 7 standard: "When the standard comes - and it certainly will - a production volume of 10 million brake discs per year will have to be handled for the European vehicle brands alone. With a cycle time for classic brake discs of around 30 seconds per disc, it's clear that the coating process will have to keep up with this."

AM Coating available in two versions

AM Coating Twin is explicitly designed for series production. The system operates with two lasers for front and rear coating, and the brake discs are transferred fully automatically. AM Coating Single is ideal for anyone who wants to test materials and material combinations, develop the application process or produce small batches in parallel to series production or in advance. On request, the Chiron Group's team of experts can provide support with process development. Either at the customer's site or in Tuttlingen. "Here," Dr. Koscsák outlines a possible scenario, "we can install a basic machine on which the customer's specialists can get to know the process, run tests and, together with us, design the parameters so that they are ready for series production. Or, for a continuous and even more productive process, integrate a grinding machine and perfectly coordinate both systems."

Cloth bonded application in the best quality

But productivity alone is not enough - the quality of the coatings must also be right. What about cracking and durability? Project manager Ernest Frombach explains: "By means of high-speed laser buildup welding, we achieve improved adhesion through a material-to-material bond. In addition, the layer thickness is smaller, in the range of tenths of a millimeter. As a result, much less material is consumed, and we achieve a high degree of powder utilization thanks to our powder management. Buffer and hard material layers are applied directly one after the other. With the application of the first layer, the brake disc is tempered, so to speak, and we consistently achieve the best application quality brake disc after brake disc without pore or crack formation." (OM-06/23)

Contact

Chiron Group SE

Kreuzstraße 75

78532 Tuttlingen (Germany)

Phone: +49 7461 940-0

E-mail: info@chiron-group.com

chiron-group.com

About Chiron

The Chiron Group, headquartered in Tuttlingen, Germany, is a specialist for CNC-controlled vertical milling and mill-turn machining centers as well as turnkey and automation solutions. Comprehensive services, digital solutions and products for additive manufacturing complete the portfolio. Key user industries are the automotive industry, mechanical engineering, medical and precision engineering, aerospace, and tool manufacturing.