Since 1988, the name Göweil has been synonymous with the highest quality product range in the field of bale wrapping and baling technology. Other core areas include the manufacture of bale breakers and transport equipment, high-tip buckets and knife grinders. Due to the extremely high export share, Göweil machines are known and used not only in Europe, but worldwide. Originally, the company specialized in the production of agricultural machinery, but now the machines are also available for industrial use. As a result, the number of employees has grown to over 300 and sales have risen to around € 50 million. As a unique selling point, the products are supplied exclusively for the professional sector, mainly to contractors. The demands on the machines are correspondingly high, which also applies to the surfaces.

New greenfield surface and assembly center

The surfaces of agricultural machinery are subject to heavy mechanical stress. Therefore, a coating with good adhesion is required. In addition to the protective function, this also has the task of presenting the value of the machine in a visually appealing way. This was recognized at Göweil and implemented accordingly.

At the beginning of 2022, a new surface and assembly center was put into operation in Rainbach im Mühlkreis, Austria. It has a floor space of approx. 16,600 m². Since then, the preliminary products from the company's own plant in nearby Kirchschlag as well as from other supplier companies have been processed and finished here. Herbert Göweil, looks at the new production facility with satisfaction: "We are very pleased with the investment. All expectations have been met. In the original paint shop in Kirchschlag, the plant was prone to breakdowns. "Large parts had to be blasted by hand, this was of course very time-consuming."

Decision for wet paint instead of powder coating

Many plans and suggestions from visits of the Göweil project team to similar production tasks from other industries formed the planning basis. Thus, the question of deciding on wet painting instead of powder painting was also quickly found. After all, wet painting would have been necessary in any case for some parts from the wide Göweil range. Incidentally, an automatic color change was made possible for the three standard colors blue, yellow and black. The first experiences and results of the new operation are now available. More than 1,000 parts are required for Göweil's products, and 90 percent of them have to be blasted in preparation for subsequent wet painting. The parts are cleaned of scale after welding.

The investment sum for the entire complex was over € 27 million and thus sets a beacon in this region. The planning was started backwards according to the production process. The area was determined on the basis of the expected assembly capacity. Also the painting plant of the manufacturer Rippert and for it upstream the wet-chemical pretreatment, the double rinsing process with adhesive water dryer and also the AGTOS blasting technology were calculated on the basis of these capacities. The treatment processes, which also include masking, were connected by a friction wheel conveyor system from the manufacturer KJ. This makes it possible to produce not only according to the "first-in-first-out" principle. The system makes it possible to determine a modified sequence. And this all the way to the assembly line. The respective processing recipes are defined and stored by the AV. Each product carrier carries a data carrier on which the specific machining parameters are stored. A second painting line has been planned for future growth. Göweil is considering using a robotic painting system here to process standard parts.

Interesting details about blasting technology

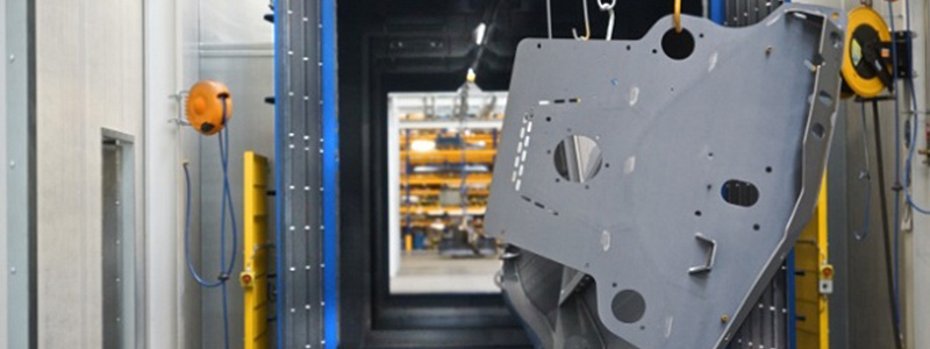

The blasting tasks are performed by an AGTOS continuous overhead conveyor blast machine type DHT 25-25. The workpieces of various types to be processed are suspended on cross beams with a length of 7,000 mm. The blast room of the plant can hold workpiece dimensions of WxH max. 2,500 x 2,500 mm. The maximum workpiece weight is 2,000 kg. Due to the quite different and angled geometries of the workpieces, the plant was equipped with 16 high-performance turbines with 11.0 kW each. Frequency converters allow the best setting of diverse processing programs. Round and angular grain can be used as blasting media. The throughput speed is approx. 1 to 3 m/min.

The abrasive is recirculated and fed back to the turbines after cleaning. Two AGTOS cartridge filter systems of type PF 04-40 ensure a residual dust content of the extracted air of </= 1 mg/Nm³. A sound enclosure reduces the sound pressure to below 80 dB(A), measured according to DIN 45635. The workpieces are blown off after the blasting process and thus freed from dust and remaining abrasive. This ensures that they are optimally cleaned before they are painted.

High degree of automation

Mathias Kapfer, project manager of the new plant, summarizes the differences to the previous state as follows: "Today, about 90 percent of the process is automated. This means that we hang the parts on the system, they travel fully automatically through the blasting system via the conveyor system. The recipes are assigned directly to the product carrier, so there is no manual manipulation or the like. The expectations and the challenges were great. It was the right decision that we did this with the company AGTOS. The biggest advantage is that we get our largest component through the system, something that was just not possible before because the large base frames were blasted by hand."

The issue of resource conservation is also viewed positively. Kapfer: "The throughput time in particular is enormous with this system. If you think back to the operation in Kirchschlag, we needed about three quarters of an hour for a large base frame by hand. Here, with automatic blasting, we need about 10 minutes. So the blasting plant and also that has changed very positively." (OM-04/23)

Contact

AGTOS GmbH

Gutenbergstr. 14

48282 Emsdetten (Germany)

Tel. +49-2572-96026-200

Email: info@agtos.de

www.agtos.com

About AGTOS

More than 160 employees work at two AGTOS locations. The company's headquarters are located in Emsdetten, while production is located in the Polish town of Konin. AGTOS is the specialist for wheel blast machines. The possible applications of the machines range from the processing of large quantities of millimeter-sized chain parts to steel structures the size of overseas containers. AGTOS shot blast technology is used by customers from the automotive and automotive supplier industry, foundries and forges, for example. Other target industries include steel traders, the fastener industry and mechanical engineering.