A new pioneering process for partial parts cleaning, which saves time and money and significantly improves production efficiency, was presented by Silberhorn at the latest in-house exhibition (as reported by Oberfläche-Online). This new process, which has already proven itself in practice, marks a significant advance in industrial parts cleaning.

A look at the innovation of partial parts cleaning

The new process for partial parts cleaning represents a real paradigm shift in the industry. "Imagine you have already cleaned parts that become dirty again during the manufacturing process - due to subsequent milling work or test runs," explains Markus Heinloth, Head of Research & Development at Silberhorn. "Previously, these parts had to be completely cleaned again, which was not only time-consuming and expensive, but also impossible in some cases, especially if sensitive electronics were installed. Then they had to be cleaned manually. This is exactly where our solution comes in: Partial parts cleaning."

How partial parts cleaning works in detail

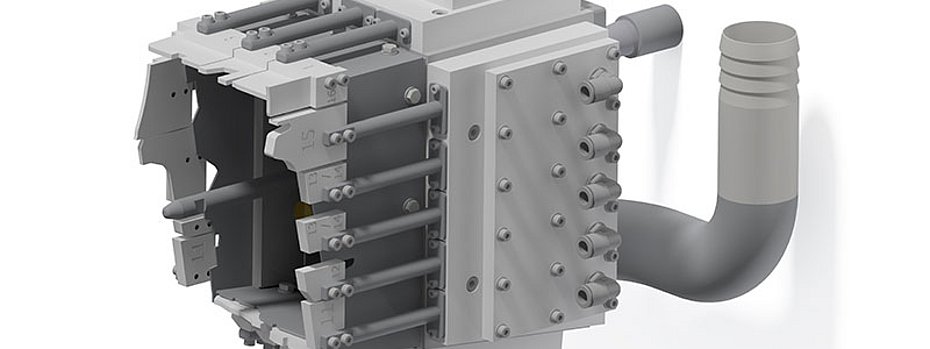

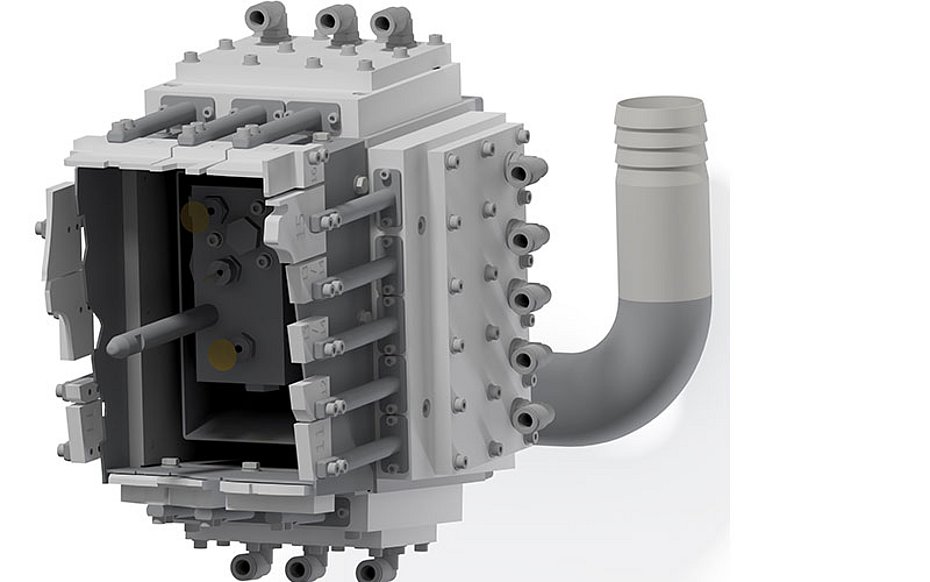

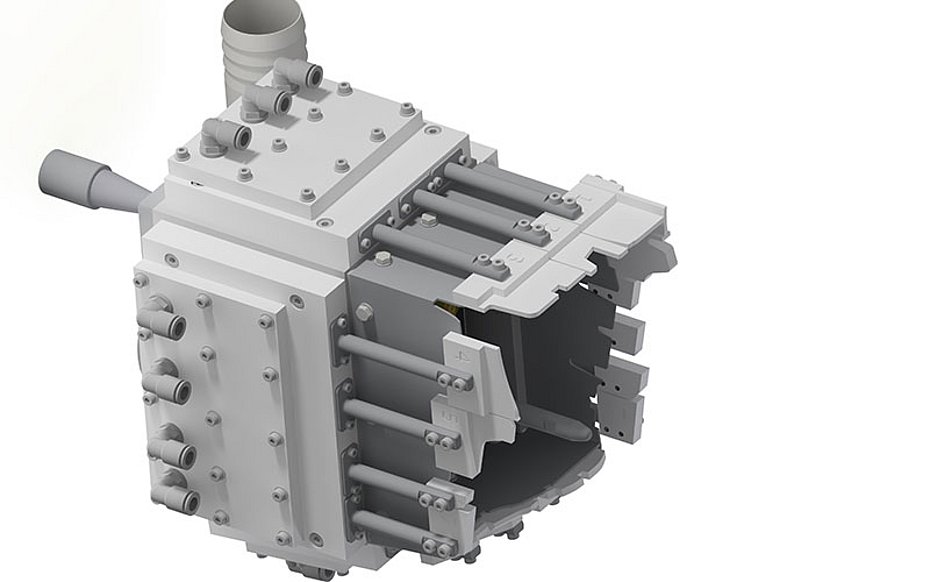

The partial parts cleaning technique is based on an innovative approach that enables precise and targeted cleaning of individual areas of a component. The process uses a specially developed "hood" that is placed on the subsequently contaminated area of the component. All cleaning and drying processes take place under this hood in a highly efficient and targeted manner.

In detail, the system works as follows: The hood has a contour adapted to the respective component (and its variants, if applicable). It is automatically placed on the component with the appropriate care. Cleaning fluids are then applied to the contaminated surface within the closed system. Specially positioned nozzles distribute the liquids evenly to effectively remove dirt and residues. The cleaning fluid with the residues is immediately extracted. The treated area is then dried - also under the hood - so that no moisture remains. This closed process reduces the impact on neighboring areas to almost zero and significantly reduces the consumption of cleaning agents and energy. The previously manual cleaning process is now automatic, reliable and integrated into the overall cycle time of the production line. After the cleaning and drying process, the hood returns to its original position and is "zeroed" so that other components can be cleaned.

"The challenge was to develop a system that offers both an exact fit and flexibility for different component variants," explains Markus Heinloth. "Our solution combines these requirements with an adaptable and mechanically optimized hood that adapts to different component shapes and thus ensures maximum flexibility." This precise and targeted cleaning is efficient, while at the same time reducing the ecological footprint: energy consumption and resources are minimized. "Cleaning and drying only takes place where it is really necessary," says Heinloth, "which saves resources such as energy, water, chemicals and much more." The areas that have already been cleaned in a pre-process and have not been re-soiled are no longer treated.

Background and challenges

Increasing environmental regulations and the need to reduce CO₂ emissions have changed the way we look at optimal cleaning solutions. While the focus used to be on pure cleaning quality, holistic considerations are now required. "Our approach not only takes cleanliness into account, but also resource conservation and cost efficiency," explains Heinloth. "With partial parts cleaning, we offer a solution that is tailored to the specific requirements of our customers and at the same time meets sustainability requirements."

Efficiency and cost-effectiveness of partial parts cleaning

The new process has remarkable advantages. A project realized for a customer shows impressive results:

- 23% lower consumption costs per year

- 25% smaller footprint

- 25% less enclosed volume

- 25% reduced investment costs

- 30% shorter process times

- 45% less energy consumption

- 45% lower cost per part

- 80% less use of resources

- 34 tons less CO₂ emissions

These calculations cover a period of 8 years. The efficiency gains result from precise and targeted cleaning, which not only saves costs but also reduces the company's environmental footprint.

Outlook and further developments

For even greater sustainability, Silberhorn is planning to integrate all of the customer's sub-processes even more comprehensively into the design solutions. "We offer to look at all upstream and downstream cleaning processes in order to tap into additional savings potential," Heinloth looks ahead. "For example, we could optimize milling processes in such a way that energy-intensive cleaning processes become superfluous, or use outfeed belts for post-drying in order to dispense with vacuum drying." With this innovative technology, the company is once again underlining its commitment to modern, resource-saving solutions that meet the modern requirements of the market. (OM-3/25)

Contact

Maschinenbau Silberhorn GmbH

Eichenbühl 2, 8

92331 Lupburg (Germany)

Phone: +49 (0)9492 9425-0

E-mail: info@maschinenbau-silberhorn.de

www.silberhorn-gruppe.de

About Maschinenbau Silberhorn

Maschinenbau Silberhorn GmbH is part of the internationally active Silberhorn Group. The medium-sized company employs around 200 people. Maschinenbau Silberhorn specializes in the development and construction of systems for industrial parts cleaning and high-pressure water jet deburring.