Paint adhesion before coating

The classic application is the flame treatment of plastic parts before painting. Here it is essential to activate the surface in order to guarantee optimum paint adhesion. In principle, optimum adhesion is always achieved when the surface energy of the workpiece is higher than that of the paint or the adhesive layer. If the surface energy is lower, it can be increased by flame treatment.

The physical process transforms the originally inert and non-polar structure of the surface, which results in poor adhesion of paints, into a material with a polar structure. The demonstrably increased surface tension generated in this way enables optimum paint adhesion to the components. This is particularly important for suppliers and manufacturers in the automotive industry who flame treat plastic parts such as bumpers or door panels in order to optimize paint quality. Paint manufacturers also use the system in laboratories to flame test panels and check the quality of their paints.

Adhesion during bonding

Flame treatment is also an effective and versatile method for improving adhesion during bonding. By increasing the surface energy, wettability with the adhesive is improved. Organic contaminants such as oils or greases are burnt off, resulting in a clean and polar surface. The thermal treatment can also lead to microstructuring, a slight roughening of the surface, which also improves the mechanical anchoring of the adhesive. This is used in the assembly of plastic parts in the automotive industry or in the manufacture of medical devices and consumables made of plastics that are difficult to bond. Flame treatment is also used for product markings that are difficult to adhere, such as stickers in the packaging industry or bonding in the electronics industry.

Deburring of plastic injection molded parts

Flame treatment is an effective method for removing fine burrs from injection molded parts and improving the surface quality. The plastic parts are briefly exposed to the flame and the heat melts thin burrs on the surface. Due to the low mass of the burrs, they melt faster than the surrounding material and thus disappear without damaging the main structure of the part. This process means that time-consuming post-processing steps such as grinding can either be completely eliminated or significantly reduced. This is used, for example, for plastic parts in medical technology.

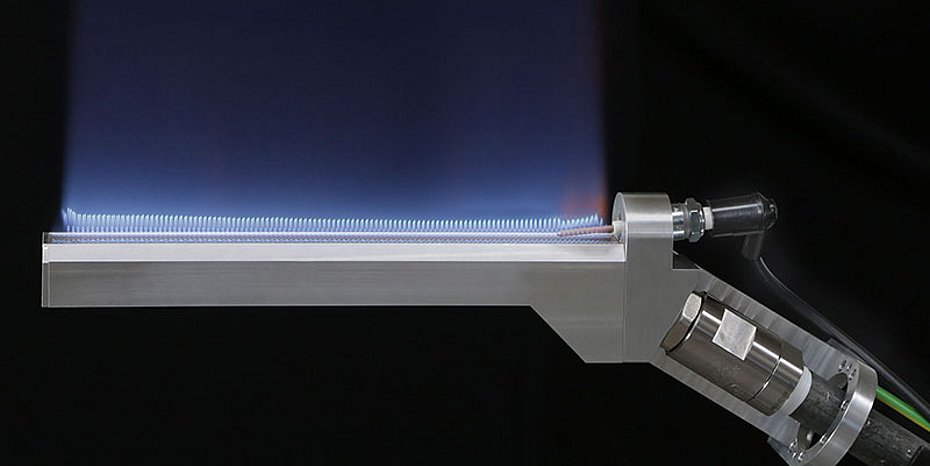

Flame treatment system integrated into production lines with robotics

The Rob-Flame system from Asis can be used as a stand-alone solution or integrated into existing systems. In the latter case, it is then clearly displayed in the main control system. This offers a high degree of flexibility and facilitates integration into existing production processes. The torch can either be guided directly by the robot or designed as a stationary torch, past which the parts move or are guided by a handling robot. The latter is particularly advantageous for deburring. You can choose between different Asis torches. Different sizes allow it to be adapted to the component geometry and size as well as to the preferred robot type with the option of internal or external hose guidance. A special fabric for distributing the air/gas mixture is used in all models and ensures a uniform flame pattern over the entire length. The advantages of robotics are obvious, as they deliver a consistent and repeatable result. The problems of insufficient flame spacing or too long/short flame exposure, which occur again and again with manual flame application, do not exist with a robotic solution.

Rob-Flame: Technical structure

The technical design of the Rob-Flame system from Asis gives it an advantage over many other systems. A key safety feature is the separate electrical and mechanical design, which allows mechanical work to be carried out independently of the electrical part and vice versa. This increases safety and makes maintenance work easier. The closed-loop system precisely regulates the flow of the air/gas mixture and ensures an extremely uniform flame pattern, which improves the quality of the flame. A small fixed panel allows the parameters to be set and the flame to be started or stopped during maintenance.

Continuous product maintenance

The current product update includes new flow sensors that provide even more precise and stable control and ensure long-term product support. A replacement kit is available for existing systems to integrate the new sensors. A new ignition transformer ignites the flame, checks that it is burning and safely switches the flame off again at performance level D, which is crucial in the event of an emergency stop.

Another advantage is the compact design of the system. With a control cabinet width of just 60 cm, the system is extremely space-saving. In addition, an experienced service team is available for maintenance and support, which guarantees the operational reliability and longevity of the system. A wide range of proprietary burners enables adaptation to different requirements, while the closed-loop system constantly monitors the status of the system and provides immediate feedback in the event of malfunctions.

Conclusion on flame treatment technology

Flame treatment is a versatile and cost-effective technique for adapting the surface quality and polarity of plastics to specific process requirements. It works very efficiently and quickly and is easy to automate. Compared to chemical deburring processes, flame treatment produces less waste and does not use any harmful chemicals. Asis has a test center to test the possibilities of flame treatment on customer-specific parts. In short and free functional tests, a basic evaluation of this technology can be made with regard to the modification of surface properties. (OM-7/24)

Advantages of flame treatment

- Cost-effective process: The equipment for flame treatment is cost-effective and can be easily integrated into existing production lines.

- Can be combined with robotics: Ideal for combining with robots, either directly on the torch or with a handling robot for optimum reproducibility

- Wide range of applications: Adjustment of surface quality for increased adhesion of coatings and bonding or deburring of plastic injection-moulded parts

- Versatility: Can be used for various materials such as polyethylene, polypropylene and polyamide as well as metals and glass

- Can be used across all industries: automotive industry, medical technology, electronics industry, packaging industry, general industry

Contact

ASIS GmbH

Kiem-Pauli-Straße 3

84036 Landshut (Germany)

Phone: +49 871 27676-0

E-mail: mail@asis-gmbh.de

www.asis-gmbh.de

About Asis

Asis GmbH solves special tasks in automated surface technology. The internationally positioned system provider exports from four locations in Germany and a subsidiary near Shanghai to over 30 countries worldwide. The range of services includes turnkey solutions in the areas of coating, application technology, quality assurance, surface treatment, electron treatment, process automation technology and digital simulation.