Vogt Stanzteile GmbH has been relying on Vapic to clean its components since 2016. Now the company is expanding the partnership: After Vapic's contract cleaning service has already impressed with first-class cleanliness, the purchase of a Vapic solvent-based cleaning system including cleaning chemicals is planned. The reason for this is the increasing demands on surface cleanliness with increasing quantities in stamping production.

Stamping and forming technology at a consistently high level

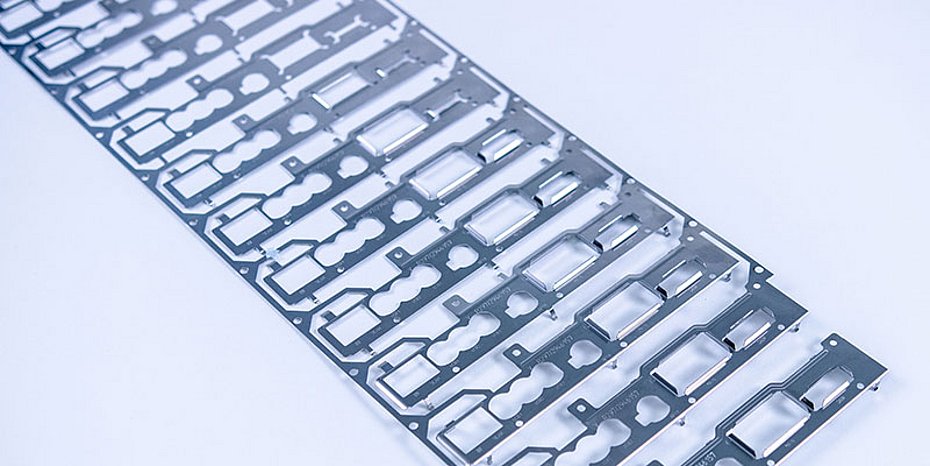

The specialist in stamping and forming technology, which was founded in 1986, intends to continue supplying these growing production volumes to its customers in the future with its usual consistently high quality. Under the motto "Made in the Black Forest", the company produces, finishes, assembles, packs and ships stamped, deep-drawn and stamped-bent parts for well-known customers in the automotive, electrical, medical technology and mechanical engineering sectors on a daily basis. The contract manufacturer sees itself as a service partner and, with a team of 45 employees, offers integrated complete solutions - from tool planning and prototyping through to series production. A central core of this value proposition are parts with flawless surface quality.

Consistently stable cleaning results thanks to contract cleaning

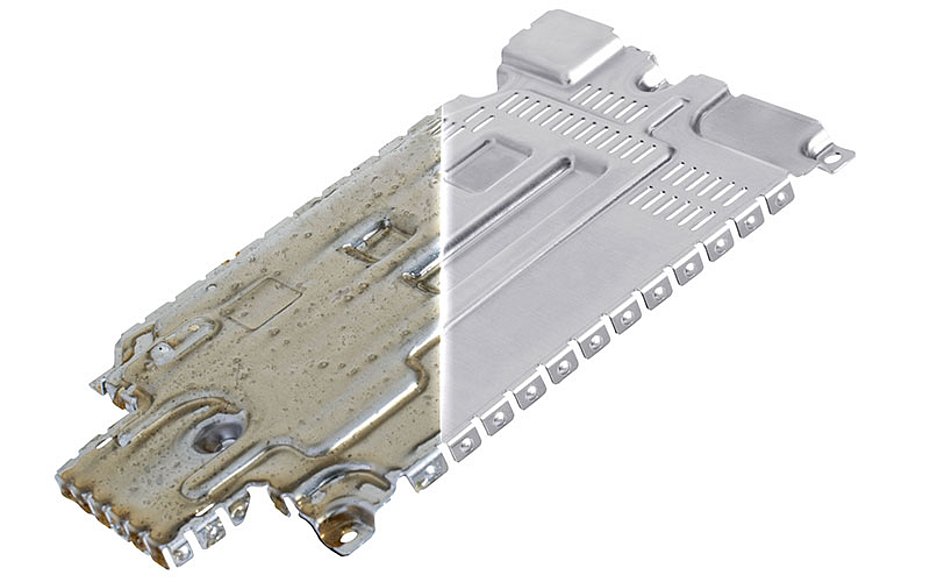

The entry into the contract cleaning service took place as part of an extensive automotive order for the production of aluminum stamped parts for electric vehicles. The aim was to achieve reliable surface cleaning so that the parts could be provided with QR codes and packaged after stamping. To achieve this, the filmic-particulate processing residues from the stamping process had to be completely removed and the surfaces had to be released from the cleaning process absolutely dry. In addition, the surface energy of the components must not impair the adhesion of the label adhesive - a challenge when working with aluminum. Discoloration of the aluminium material should also be prevented. Due to the required surface energy, a solvent-based cleaning process with perchloroethylane (PER) was ultimately chosen. Further arguments in favor of PER were the better creeping effect of the cleaning medium, which enables larger batches with a small distance between parts. "The cleaning results are also more stable over a longer period of time," explains Samuel Wolf, Managing Director of Vapic.

In view of the cost of an in-house system, Vogt initially opted for contract cleaning: "We had to find a high-quality solution for the cleaning requirements quickly. Vapic proved to be a suitable partner," says Michael Gall, Managing Director of Vogt Stanzteile. Martin Waidelich, Head of Quality Assurance, adds: "The combination of system technology, regional proximity and vapic's many years of expertise, as well as a partnership-based approach, led to consistently reliable cleaning results that met the high requirements."

Customized cleaning system for growing production volumes

After eight years of successful contract cleaning, Vogt Stanzteile is planning the next step: its own perchloroethylene system from Vapic. The customized model corresponds to the previous contract cleaning system and is expected to be installed in spring 2026, as soon as the new factory building at the Seewald-Besenfeld site is completed. With the acquisition, Vogt is also purchasing the proven cleaning chemicals from Vapic. The investment is a response to the growing order volume, which makes the economic advantages of having its own system appear plausible. "We are growing with the requirements of our customers and strive for consistent quality even with high volumes. By expanding our cleaning capacities, we want to enable a broader product portfolio in the long term," says Michael Gall. The new system should increase process reliability and avoid bottlenecks.

Overview of the planned PER system and the cleaning process

The system is currently still in the project planning phase. An application has been made for funding for this, as the energy-efficient design of the system means that a high percentage of funding is available. "Vapic also provided us with expert support here," says Michael Gall. A single-chamber system with front loader and vacuum distillation is planned. The vacuum-proof working chamber is connected to two tanks with a capacity of 4,400 liters each, which are responsible for pre-cleaning and ultra-fine cleaning. With a batch size of 1.2 x 0.8 x 1 m (L x W x H), the system is designed to handle high cleaning volumes with a cycle time of around 15 minutes in single-shift operation. The work chamber is loaded and unloaded by a fully automatic shuttle vehicle. The employee's only task is to place the pallet cages to be cleaned in the designated storage areas in front of the system and to assign the appropriate cleaning program to the respective batch. He also has to remove the cleaned pallet cages from the storage locations later. Vapic has planned a storage system with eight storage locations for this purpose, so that the system can clean fully automatically for up to two hours and downtimes can be avoided.

The Vapic energy-saving process combines distillation, vapor evaporation, vacuum and compression and ensures more economical operation. During the cleaning process, the energy is kept in the system at many points by intelligent solutions and is used to heat the tanks, among other things, which significantly reduces energy consumption. The cleaning process comprises the phases pre-vacuum, pre-cleaning, ultra-fine cleaning, active superheated steam degreasing and vacuum drying.

Contract cleaning remains part of the strategy

Alongside this system, Vogt Stanzteile will continue to use contract cleaning at Vapic - particularly in the event of delivery bottlenecks or project-related peaks. The investment in autonomous capacities is a strategic measure to more closely interlink quality, delivery reliability and efficiency in the future. "In this way, we can continue to respond flexibly to customer requests. The cooperation with Vapic will remain closely anchored and will be further developed in a targeted manner," explains Michael Gall (OM-11/25).

Contact

Vapic GmbH

Harry à Wengen Straße 6

75387 Neubulach-Oberhaugstett (Germany)

Phone: +49 7053 968130

E-mail: info@vapic.de

www.vapic.de

About Vapic

Vapic is a provider of products and services for industrial parts cleaning based in Neubulach-Oberhaugstett (Black Forest). The portfolio of the medium-sized family business comprises three areas: Special plant construction, contract cleaning and the manufacture of cleaning agents. Vapic solutions are used in almost all sectors, mainly in the automotive industry, medical technology, the composites sector and the white goods industry.