Acp Systems is expanding the range of applications for QuattroClean snow blasting technology with an innovative, cycling dual-substance ring nozzle. In addition, the new development enables savings of up to 15 percent in carbon dioxide and compressed air consumption. For some time now, the trend in industrial parts cleaning has been toward processes with which particulate and filmic contamination can be reliably removed dry and, if necessary, selectively. Another aspect that is becoming increasingly important is the simple and space-saving integration of the cleaning process into production lines. The QuattroClean snow blasting technology from Acp Systems AG, which uses liquid, climate-neutral carbon dioxide as a cleaning medium, scores highly in all these requirements.

Clocking nozzle saves operating costs

To expand the range of applications for the cost-efficient and sustainable cleaning process, the company has designed an innovative two-substance ring nozzle that generates a pulsed jet. For this purpose, the wear-free nozzle is equipped with a valve specially developed by Acp for this application, which enables cycle times of up to 20 milliseconds. Compared to pilot-controlled standard valves, the direct control of the valve prevents icing and thus ensures reliable operation and consistently good results.

The blasting and pause times can be set independently of each other, so that the cycles can be optimally adapted to the respective application and the part-specific treatment sequence. At the same time, the clocked blasting pulses result in savings in CO2 and compressed air consumption. Depending on the cycle, these savings are between ten and 15 percent. The innovation from Acp Systems took third place in the first FiT2clean Awards 2022, which are presented annually by the Fachverband industrielle Teilereinigung e.V. (FiT) to honor outstanding achievements and solutions for component cleaning.

New applications in cleaning, deburring and machining

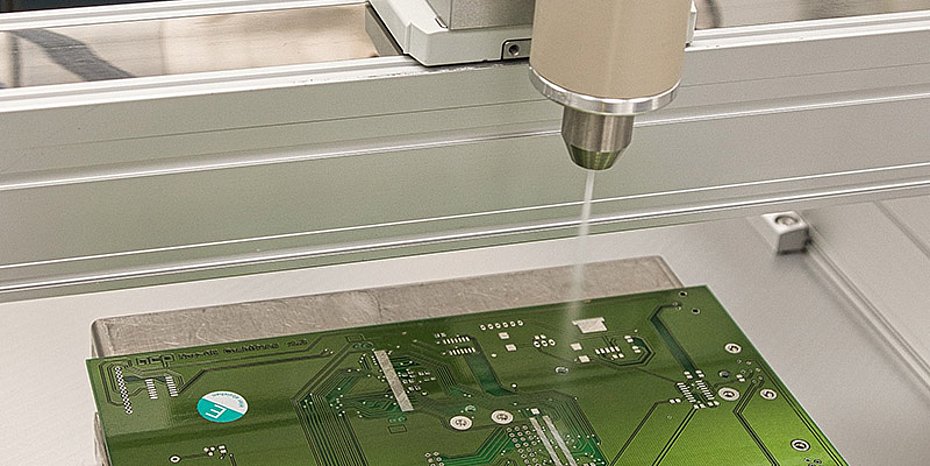

In contrast to continuous blasting, the pulsed CO2 compressed air jet has a higher kinetic energy, which makes it slightly abrasive. This opens up possible applications where classic CO2 snow blasting previously had to pass. These include, for example, the cleaning of loosely adhering welding beads after welding processes, as well as the removal of particulate contamination adhering to metallic components due to dried processing medium. When it comes to cleaning flux residues and particles from bonding surfaces, the indexing nozzle also offers advantages.

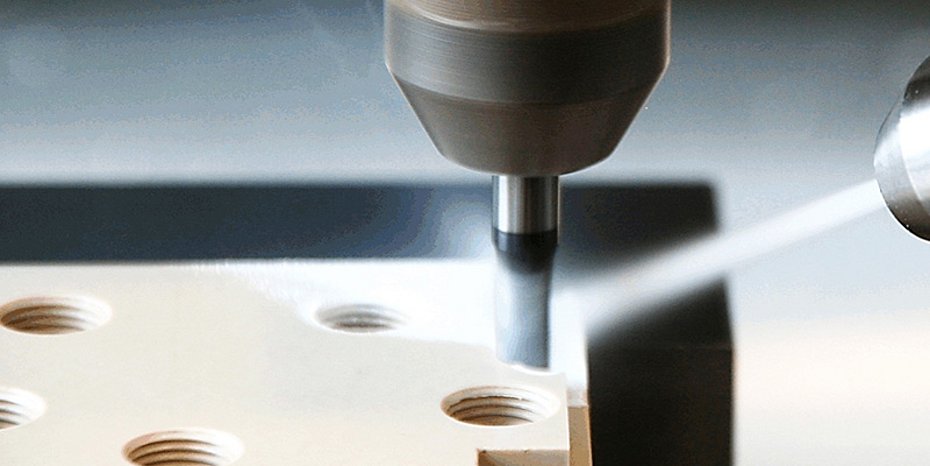

Another area of application is the removal of partial film residues after hot stamping or laminating aluminum onto plastic parts. The pulsed CO2 compressed air jet also has sufficient cleaning power to remove fine flake burrs from aluminum and zinc die-cast parts. It can also be used for simultaneous deburring and cleaning of hard and brittle plastics, such as PEEK and PPS. When machining these plastics and aluminum components, the new dual-substance ring nozzle also offers optimization potential. As an alternative to conventional cooling lubricants, the cold snow crystals of carbon dioxide enable an increased metal removal rate and thus improved productivity as well as reduced tool wear. In addition, there is significantly reduced contamination of the components and machine.

Four mechanisms of action ensure result

The wear-free two-substance ring nozzle is the "heart" of the process. The liquid carbon dioxide is passed through it and expands into snow crystals as it emerges. They are focused by a separate compressed air jacket jet and accelerated to supersonic speed. When the jet, which is easy to focus, hits the surface to be cleaned or deburred, a thermal, mechanical, solvent and sublimation effect occurs. Through the interaction of these four mechanisms, particulate and filmic contaminants are removed just as reproducibly as fine flake burrs. The detached contaminants or burrs are transported away from the component by the aerodynamic force of the compressed air jet and removed from the process chamber by an integrated suction system. Since the CO2 sublimates under atmospheric pressure, the parts are immediately dry and can be further processed directly. In machining operations, QuattroClean snow blasting technology enables the chips produced to be clean, dry and easy to recycle.

The scalable QuattroClean process can be adapted to different component geometries for full-surface or partial cleaning in a space-saving and efficient manner. The process parameters are determined by trials in the company's own pilot plant. The cleaning systems are designed to suit the cleaning task and cycle time requirements on the basis of standard modules. Stand-alone systems are implemented as well as solutions integrated into automated and/or interlinked production lines. (OM-4/23)

Contact

Acp Systems AG

Berblingerstraße 8

71254 Ditzingen (Germany)

Tel: +49 (0)7156 / 48014 - 0

www.acp-systems.com

Acp Systems AG

Acp Systems AG is a global technology leader in advanced clean production, related process automation and system integration headquartered in Germany. The core technologies are QuattroClean snow jet cleaning, microdosing and intelligent handling solutions for flexible materials and films.