Adapted to extremely high particulate and filmic cleanliness requirements, which have to be met for high-tech components in an increasing number of industries, Acp Systems AG has expanded its test capacities. The design and equipment of the new cleanroom pilot plant enable cleaning tests up to cleanliness class ISO 5 to be carried out using dry QuattroClean snow blasting technology and the cleanliness achieved to be verified.

Clean room designed snow blasting technology

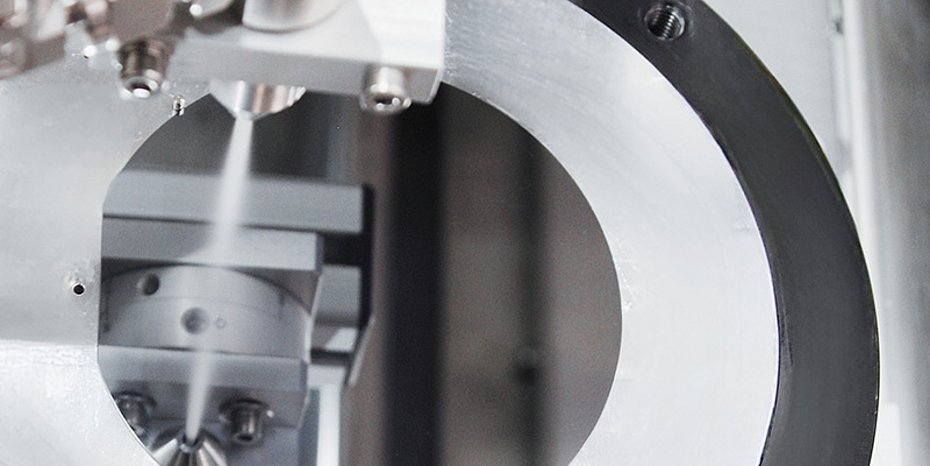

Whether metallic, optical or plastic components, the demand for high-purity components is continuously increasing across all industries. Particulate cleanliness requirements down to the submicrometer range and extremely high cleanliness levels with regard to filmic-organic and inorganic residual contamination must be met. Acp systems AG has reacted to these changes with cleanroom-compatible solutions of its QuattroClean snow blasting technology. This is a dry process for full-surface or partial component cleaning. The cleaning medium is climate-neutral liquid carbon dioxide, which is fed through a wear-free two-substance ring nozzle, expanded to form fine snow particles and bundled by a compressed air jet on the surface to be cleaned to remove particulate and filmic contamination by four mechanisms of action. QuattroClean cleaning systems are used by manufacturers in the sensor and microsystems technology, electronics, semiconductor supply, precision optics, aerospace, medical and pharmaceutical technology, communications technology and automotive industries, among others, in cleanrooms of various ISO classes. To enable customers from these industrial sectors to carry out cleaning tests under ultra-clean conditions, the company took the next step on its 25th anniversary: A cleanroom technical center was built at the Ditzingen site and completed in mid-June 2023.

Design and equipment for tests up to cleanliness class ISO 5

The basis of the new pilot plant is a validated ISO 7 class cleanroom with zones up to class 5 according to ISO 14644-1. The design and equipment of the two integrated JetStation-HP cleaning systems also meet the high requirements of cleanroom class 5. The media preparation system for the liquid carbon dioxide ensures a purity of the process medium of 99.995 percent. The compressed air preparation system ensures quality 1.2.1. in accordance with ISO 8573-1:2010. Integrated into this ultra-clean media supply for compressed air (XCDA) is also a gas scrubber that filters out traces of organic substances to produce the air quality required in semiconductor production, for example.

The new cleanroom technology thus opens up the possibility of carrying out cleaning trials and feasibility studies on a very wide range of components with extremely high cleanliness requirements, for example Grade 1. This includes components which cannot be cleaned wet-chemically due to their dimensions or because they are already pre-assembled, or for which the required cleanliness cannot be reproducibly achieved with previously used processes. Various detection technologies are available for checking the achieved cleanliness. Any necessary transport of the cleaned components is carried out in packaging suitable for cleanrooms.

Clean room test laboratory for cleanliness requirements down to 100 microns

The new cleanroom pilot plant complements the test laboratory, which has been integrated into a cleanroom for many years. It is typically used for cleaning tasks from various industries where technical particulate cleanliness down to 100 micrometers is required over the entire surface or in parts. The cleanroom test laboratory is therefore also suitable for preparing components for cleaning in the cleanroom (OM-1/23).

Contact

Acp Systems AG

Berblingerstraße 8

71254 Ditzingen (Germany)

Tel: +49 (0)7156 / 48014 - 0

www.acp-systems.com

Acp Systems AG

Acp Systems AG is a global technology leader in advanced clean production, related process automation and system integration headquartered in Germany. The core technologies are QuattroClean snow jet cleaning, microdosing and intelligent handling solutions for flexible materials and films.