The cleaning of paint-contaminated parts and components is an important task in many paint-processing industrial plants where, for example, paint supply systems are used. This often involves the use of flammable, highly combustible cleaning liquids which, if used incorrectly, can not only pose a potential explosion hazard, but also a considerable health risk for the user, especially during manual cleaning operations. In order to minimize these risks and ensure the health protection of employees, it is imperative that the cleaning equipment used complies with the ATEX directives that apply to potentially explosive atmospheres.

Purely pneumatic ATEX-compliant parts cleaning device

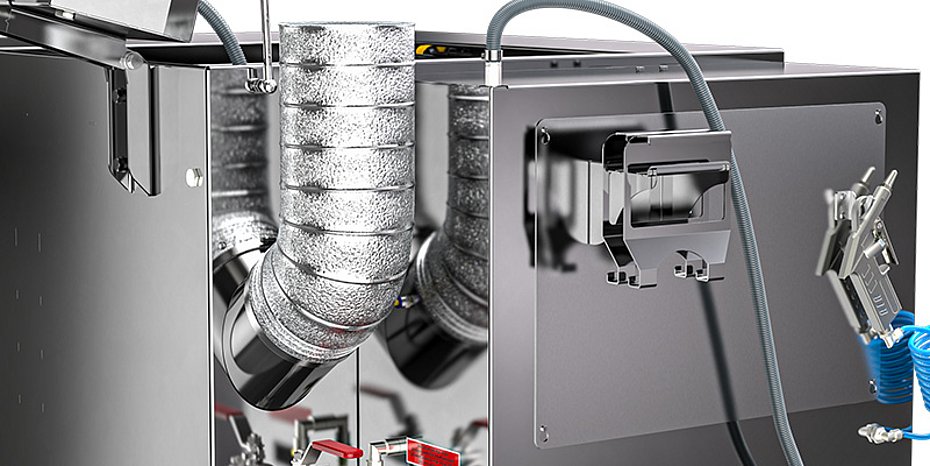

The company B-TEC GmbH now offers an innovative solution for ATEX-compliant parts cleaning with CleanTwist. CleanTwist is the only purely pneumatic, ATEX-compliant parts cleaning device with rotating parts basket worldwide. With its pneumatically driven rotating basket (standard version with Ø590mm), CleanTwist can automatically clean several parts and components simultaneously. Highly flammable cleaning fluids such as 100 percent acetone can also be used.

Compared to static or manual parts cleaning systems, the rotating basket ensures that each area of the part to be cleaned is evenly wetted with cleaning fluid to achieve a 100 percent reproducible cleaning result. In addition, CleanTwist can be optionally equipped with an automatic clear rinse to clear rinse all parts with fresh cleaning liquid at the end of the automatic cleaning process, thus always ensuring a perfect cleaning result, even if the circulating liquid is already heavily soiled. In this way, the circulating liquid can be used significantly longer and even higher solvent savings can be achieved.

Solution for parts cleaning with highly flammable cleaning liquids

With the help of the standard B-TEC extraction system, hazardous vapors are immediately extracted from the unit as soon as the unit flap is opened. The user is protected in the best possible way and contact with solvents is massively reduced compared to time-consuming manual cleaning.

CleanTwist is thus a safe, efficient and environmentally friendly solution for parts cleaning with highly flammable cleaning liquids in hazardous areas. (OM-1/23)

Contact

B-TEC GmbH

Zunftweg 6-8

31303 Burgdorf Ehlershausen (Germany)

Phone: +49 (0) 50 85 - 97 100 0

E-mail: info@btecsystems.de

www.btecsystems.de

About B-TEC

B-TEC GmbH develops and produces innovative, environmentally friendly, ergonomic and high-quality systems and equipment for paint processing companies. The company's history began in 2000 with an innovative idea for paint spray gun cleaning. Today, B-TEC GmbH is an internationally operating, medium-sized equipment and plant engineering company in the painting accessories industry.