Digital simulations instead of trial and error: In the PaintVisco project, researchers at Fraunhofer IPA are modeling the development and processing of paints. The data for this is provided by a newly designed rheometer, which for the first time can be used to precisely measure the viscoelastic properties of paints during drying and curing - the model for the technology development was the bat's echo location.

Simulation program instead of trial-and-error tests

How long does the coating remain flowable? How well does it even out unevenness? Under what conditions does the desired, mirror-smooth surface form? "Until now, painters had to try out in costly and time-consuming trial-and-error tests when a paint layer would run optimally," explains Dr. Fabian Seeler. In the PaintVisco project, he has now developed a simulation program that can be used to virtually determine the properties of coatings.

Developing the computer model was a real challenge for the Fraunhofer IPA researcher and his team, because paints are viscoelastic. This means that - depending on time and temperature - they change their properties: At first they behave more like liquids, later more like solids. The viscoelasticity, in turn, is crucial for predicting the flow, i.e. the ability of a paint to compensate for unevenness - this can be superficial brush marks, but also pores, wave structures and edges under the paint layer.

A new measuring technique provides the data

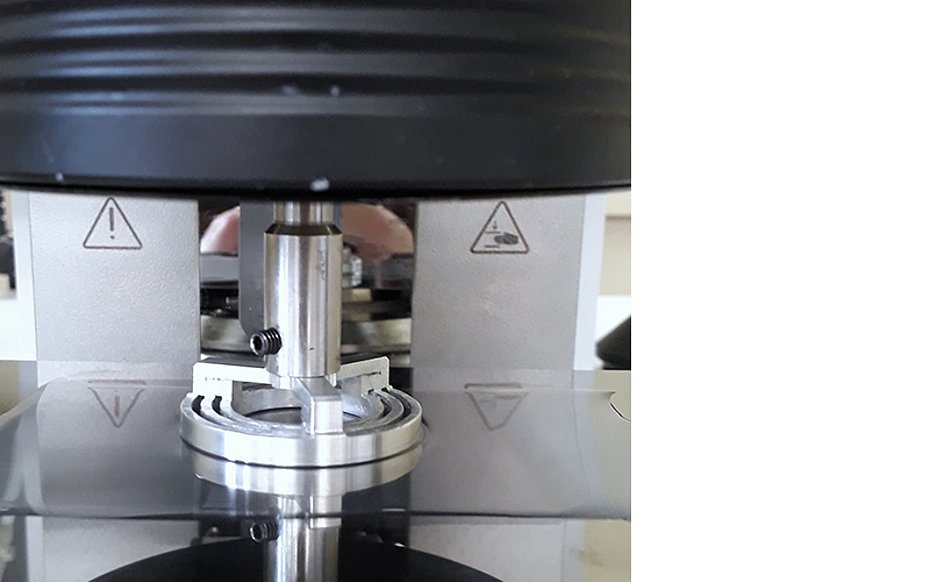

To simulate this very complex behavior of coatings, one needs a wealth of data. The measuring instruments that are to provide this are called rotational rheometers. They determine the flowability of paints by causing a thin liquid paint sample to rotate or vibrate with a disk attached, and then measure what force is needed to deform it. "However, previous devices prevent the solvents from evaporating, so the results are of limited use to the paint industry. In addition, such measurements always show only a small arbitrarily selected section of the material behavior, since measurements are often made with only a single vibration frequency," Seeler reports. For computational projections, however, one needs much more comprehensive information about the material behavior, for example the behavior of a paint sample at numerous frequencies.

Together with his team, he has developed a new measurement technique. Nature was the inspiration: "We copied the measuring principle from the bat," recalls the researcher. The bat uses short ultrasonic calls for orientation: each call contains low and high frequencies that flow into one another and are reflected by the environment. From the echo, the bat recognizes, for example, where obstacles or prey are located. By repeating the call, the bat can track how the distance to an obstacle changes over time or how the prey animal moves.

Like the bat, the PaintVisco rheometer works with smoothly merging frequencies. However, it is not ultrasonic calls that are varied, but the frequencies at which the paint sample is deformed. By repeating the sequence of frequencies, the change in viscoelastic paint properties during setting can be recorded. This special signal form makes it possible to determine all the data needed for progression prediction within a very short time, Seeler emphasizes.

With the new measurement technology, the researchers at Fraunhofer IPA can now also take into account solvent evaporation, which is so important for industry: In their rheometer, the paint layer is no longer deformed by a closed disk, but by a construction of several rings. The openings between the rings allow the solvent to evaporate.

"Our measurements have shown that the multifrequency measurement technique can be used to determine the change in the viscoelastic properties of the paint layer over the entire coating process - from application to drying at room temperature to curing in an oven," Seeler reports. "With the help of this data, we can now not only track the changes in the course-determining material properties of a paint layer during curing, but also make digital course predictions and derive optimized paint properties - regardless of whether the paint surfaces were created with a brush or an atomizer."

Simulations that save resources

The development and introduction of a new paint takes several years and costs millions. In the future, PaintVisco simulations can help manufacturers optimize the performance of their paints at the development stage, bring new products to market faster and provide them with additional information for users. Detailed information would help paint stores to save on expensive test runs and thus achieve optimum results more quickly - advantages that can be decisive for competition in times of rising gas or electricity prices and staff shortages.

Awards

prizes already underline how great the significance of the project results is for industry. Dr. Fabian Seeler supervised the student thesis of Nicolas Keinath. It was awarded the Esslingen University of Applied Sciences graduate prize donated by the coatings manufacturer Mankiewicz. Together with Dr. Oliver Tiedje, Seeler also received the Coatings Chemistry Award of the German Chemical Society. (OM-1/23)

Contact

Fraunhofer Institute for Manufacturing Engineering and Automation IPA

Nobelstr. 12

70569 Stuttgart (Germany)

www.ipa.fraunhofer.de

About the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA)

The Fraunhofer IPA was founded in 1959 and employs a staff of almost 1200. Organizational and technological tasks from production make up the research and development focus. Methods, components and devices up to complete machines and plants are developed, tested and exemplarily applied. The 19 specialist departments of the Fraunhofer IPA cover the entire field of production technology and cooperate on an interdisciplinary basis with industrial companies in the automotive, mechanical and plant engineering, electronics and microsystems technology, energy, medical and biotechnology, and process industry sectors.