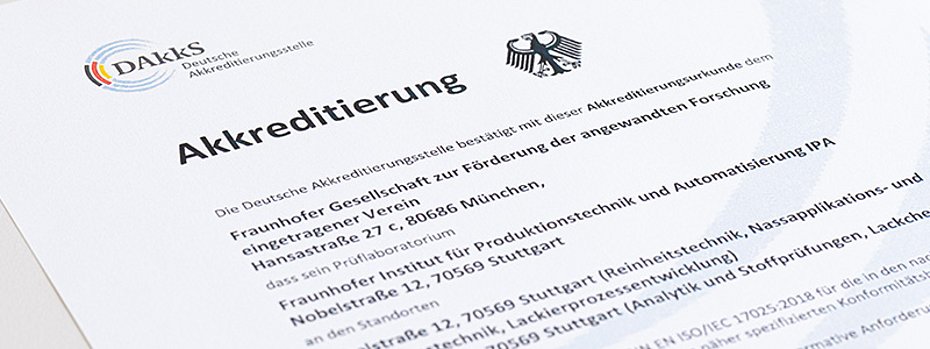

Laboratory accreditation: New accreditation certificates for Fraunhofer IPA

The departments of Coating Systems and Painting Technology and Ultrapure and Microproduction at Fraunhofer IPA have received new accreditation certificates from the German Accreditation Body. This means that further departments have been accredited to DIN EN ISO/IEC 17025 for the testing of research, industrial and medical products.

The globally valid standard for laboratory accreditation in the field of testing and calibration is defined by DIN EN ISO/IEC 17025. The standard contains general requirements for the competence, impartiality and uniform operation of laboratories. As the national accreditation body of the Federal Republic of Germany, the German Accreditation Body (DAkkS) has approved additional departments at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA.

For the complete accredited area, the requirements of DIN EN ISO/IEC 17025 are consistently implemented with the aim of achieving valid, reproducible and comparable test results. The accredited test laboratory of Fraunhofer IPA regularly demonstrates to the German Accreditation Body both its expertise in implementing the requirements of the respective test standard in conformity with the standard and its fulfillment of the requirements of the quality management system according to DIN EN ISO/IEC 17025, which forms the framework.

Purity testing technique and testing for in vitro cytotoxicity accredited

The Purity Technology organizational unit from the Ultrapure and Microproduction department is now newly represented in the DIN EN ISO/IEC 17025 accredited area with procedures from the purity testing technology for evaluating the technical cleanliness of components (according to VDA Volume 19 Part 1 and ISO 16232) with the light-optical analysis and testing for particulate contamination (microscopy) of medical devices (VDI 2083 Sheet 21).

Also new and located in the same organizational unit is the DIN EN ISO 10993-5 accredited procedure for testing in vitro cytotoxicity. In these procedures, experts from Fraunhofer IPA test whether chemical substances are capable of damaging cells and tissue. When determining the cytotoxic potential, important information is thus provided on the body compatibility (biocompatibility) of materials. Here, too, there is now approval for testing research and industrial products as well as approval for testing medical devices - additionally confirmed by the Central Office of the Federal States for Health Protection with regard to Medicinal Products and Medical Devices (ZLG). For both test areas, further test procedures are in preparation for inclusion as accredited procedures.

Accredited test methods in coating systems and painting technology

The test procedures accredited for many years in the Coating Systems and Paint Technology department consist in the subject areas of corrosion and climatic tests, physical-technical tests, coating thickness measurements and resistance tests on coated materials. Selected analytical tests and the determination of the so-called fogging behavior are also included. Fogging is the condensation of evaporated volatile components from the interior trim of motor vehicles on the glass panes, especially on the windshield. The accredited methods also include testing of the burning and odor behavior of materials used in vehicle interiors. The accredited test methods are divided among the organizational units Analytics and Substance Testing, Paint Chemical Application Technology, Paint Process Development and Wet Application and Simulation Technology.

New accreditation certificates for flexible scope

In the new accreditation certificates, all accredited test methods are now based on a normative document (e.g. DIN EN ISO) recognized by the German Accreditation Body for the flexible scope. Consequently, this means that factory test specifications are no longer listed in the accreditation certificate.

Another innovation of the accredited scope, which has also found its way into the accreditation certificate, is the change of the already mentioned flexible scope. For all current approved material tests (tests of medical devices are excluded) the accredited testing laboratory could introduce the "flexible scope category I". This flexible scope offers the possibility to flexibly and promptly include new test methods in the accredited scope on the basis of a recognized normative document within the approved accredited test areas that have proven themselves in practice. The accreditation certificates and the current accreditation scope of the respective approved test methods can be viewed on the Fraunhofer IPA website. (OM-05/23)

Contact

Fraunhofer Institute for Manufacturing Engineering and Automation IPA

Nobelstr. 12

70569 Stuttgart (Germany)

www.ipa.fraunhofer.de

About the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA)

The Fraunhofer IPA was founded in 1959 and employs a staff of almost 1200. Organizational and technological tasks from production make up the research and development focus. Methods, components and devices up to complete machines and plants are developed, tested and exemplarily applied. The 19 specialist departments of the Fraunhofer IPA cover the entire field of production technology and cooperate on an interdisciplinary basis with industrial companies in the automotive, mechanical and plant engineering, electronics and microsystems technology, energy, medical and biotechnology, and process industry sectors.