Many products consist of complex multi-component mixtures. Long-term homogeneity and durability of such mixtures is often a high priority in product development because segregation processes have a negative impact on product quality. Traditionally, such segregation processes are observed with the naked eye in a so-called "shelf life test". However, this procedure is very subjective and often several weeks of testing are required for each optimization round.

Measurements at sub-zero temperatures possible for the first time

To solve this problem, the German laboratory instrument manufacturer DataPhysics Instruments offers the dispersion stability analysis system MultiScan MS 20 for automatic stability and aging analysis of liquid dispersions. The instrument was specially developed for characterizing suspensions and emulsions and enables time- and position-resolved analysis of segregation processes. With the MultiScan MS 20, such processes can be quantified much more accurately and evaluated in greater detail than with a conventional shelf-life test. The MultiScan MS 20 consists of a base unit to which up to six sample chambers can be connected.

Up to now, the MultiScan MS 20 allowed measurements at constant temperatures and individually definable temperature profiles between 4 °C and 80 °C. The MultiScan MS 20 is now able to measure the temperature of the sample chambers. Now the laboratory instrument manufacturer has succeeded in lowering the minimum temperature for measurements to -10 °C. In order to measure at sub-zero temperatures, the tower-shaped sample chambers of the MultiScan MS 20 are encased in an insulating sleeve. To prevent humidity from condensing on the samples, the sample chambers are flooded with dry inert gas during measurement. The sleeves can be ordered in the desired quantity when purchasing a new instrument. Existing instruments can be retrofitted inexpensively for measurements at low temperatures.

Real storage conditions of many industries can be mapped

Temperature is one of the factors influencing segregation processes in dispersions. Therefore, when investigating new or optimized mixtures, it is essential to study them under real storage conditions. Dr. Sebastian Schaubach, Chief Innovation Officer at DataPhysics Instruments, says: "We are particularly pleased to be the first manufacturer in this field to succeed in performing measurements at sub-zero temperatures." Further development of the MultiScan MS 20 has made it possible to examine dispersions under real storage conditions, even for products that are stored under refrigeration. The European Medicines Agency, for example, requires in its 2007 guidelines on the "Declaration of Storage Conditions" that medicines be tested for stability and then provided with appropriate labels. Here, storage in the refrigerator is based on a temperature of around 5 °C, while storage in the freezer is based on a temperature below 0 °C.

The extended temperature range is interesting not only for the pharmaceutical industry, but also in the food sector. Here, products are often stored refrigerated during production, transport and at end customers. The typical temperature of a refrigerator is often specified as 4 °C or lower. These conditions can now be mapped with the MultiScan MS 20. Similarly, the MultiScan MS 20 can now be used for products that are used outdoors. These include lubricants as well as paints and agricultural products. "The experts in our in-house laboratory combine an in-depth understanding of our measurement methods with a broad knowledge of specific applications in many industries," explains Schaubach. He continues, "We are also pleased to accompany customers on new, exciting measurement tasks in sub-zero temperatures." (OM-05/23)

Info: Measuring principle of the MultiScan MS 20 briefly explained

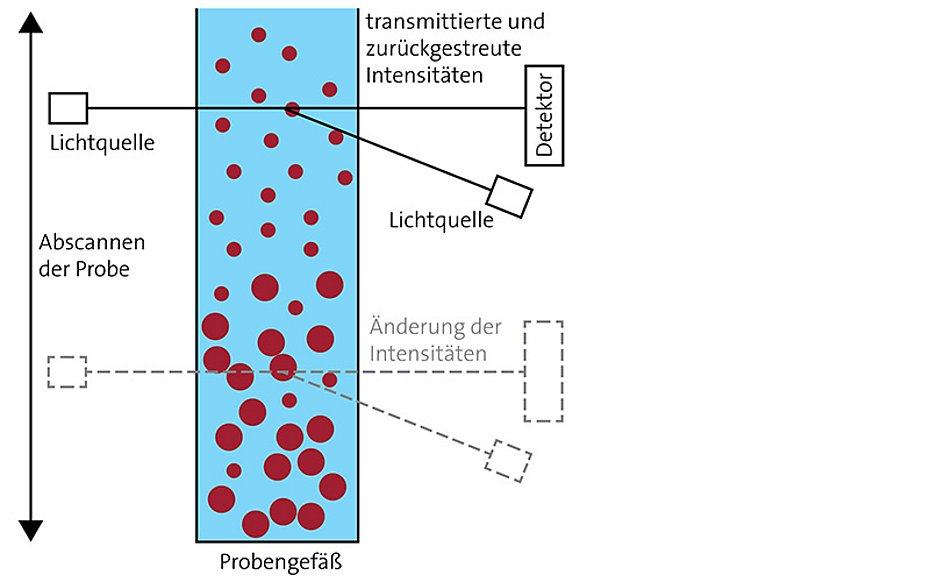

The MultiScan MS 20 analyzes segregation processes by measuring light intensities with time and position resolution. The experimental setup is as follows: A sample is placed in a glass vessel, which is then placed in a sample chamber called the ScanTower. Two light sources and a light detector move up and down along the sample simultaneously. During the measurement, the entire height of the sample is scanned. The software analyzes the light intensities that pass through and are backscattered by the sample. The intensities of transmission (i.e., the light that passes through the sample) and backscatter (i.e., the light that is reflected from the sample) depend directly on the number, size, and type of dispersed droplets or particles. Particles can settle to the bottom of the sample container, so more particles interact with light in that layer. Particles can also frame up and collect at the top of the liquid, so more particles interact with light in the top layer. The sample then shows decreasing transmission intensities in the respective region of dispersion, while the backscatter intensities increase. In addition, particles can aggregate and droplets agglomerate, which can be observed as global changes in transmission and backscatter intensities.

Contact

DataPhysics Instruments GmbH

Raiffeisenstraße 34

70794 Filderstadt (Germany)

Phone +49 (0)711 77 05 56 0

E-mail: info@dataphysics-instruments.com

www.dataphysics-instruments.com

About DataPhysics Instruments GmbH

DataPhysics Instruments GmbH has been manufacturing measurement technology for the investigation of interfaces and surfaces for 25 years. DataPhysics Instruments instruments can be used to determine important physical and chemical parameters, such as surface tension and energy, adhesion force, static and dynamic contact angles, roughness profiles, zeta potential and destabilization mechanisms.