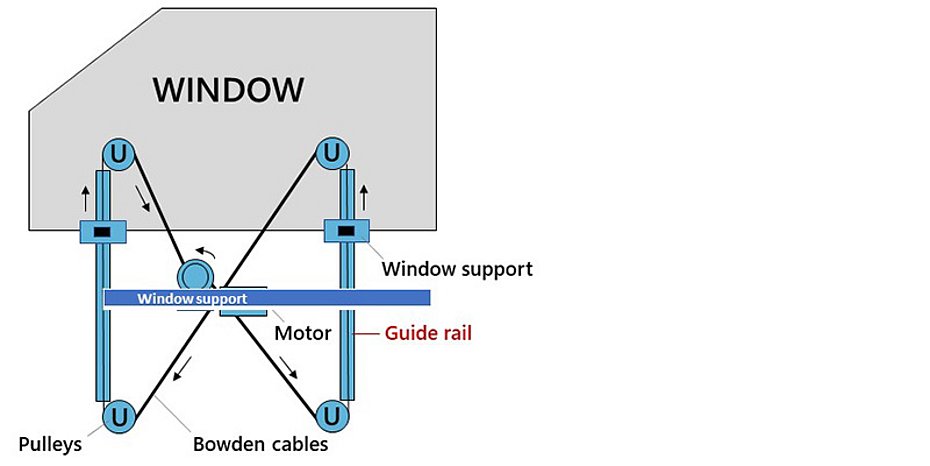

In Upper Franconia, the Metob Group coats many guide rails for car windows every day. If too little powder is applied, there is insufficient corrosion protection. If the coating thickness is exceeded on one of the two sides of the guide rail, the window regulator will jam later. The coating thickness is therefore a functionally relevant variable. The editorial team visited the Metob group of companies and spoke with managing partner Marco Jobst and quality manager Martin Kolenda about the challenges of the demanding coating from the automotive industry.

Employees as a success factor

When asked what distinguishes the Metob group of companies, Marco Jobst immediately answers "our employees". The process technicians for coating technology are real specialists and many of them have already completed their training here, the managing partner continues. The fact that numerous positions in quality management and production at Metob are now filled by the company's own former trainees is thanks to the longstanding quality and training manager Martin Kolenda, who, as a master automotive technician and environmental engineer in process engineering, is able to pass on a great deal of know-how to the trainees. With great practical relevance, the trainees learn how to control the plant parameters for a perfect surface. This knowledge, coupled with the team's many years of experience, is a competitive factor that should not be underestimated for the total of eight lines - four powder coating lines, three cathodic dip coating lines, and one line for washing, pickling, and preservation.

Eight plants for a wide range of coating tasks

In powder coating technology alone, the spectrum of Metob systems ranges from a small manual coating system to automatic booths for series parts to fully automatic, complex coating systems; the latter with a large pretreatment section. In this way, each individual customer order can be produced in a highly economical and sustainable manner. The customers are mainly from the automotive environment as well as from the furniture and baby carriage industries. For the automotive clientele, guide rails for passenger car window regulators are coated on both sides daily on the fully automated powder plant "Number 4".

The efficient journey of the components through the coating line

After the guide rails have been delivered and received, the substrates embark on a good 200-meter journey through the circulation conveyor system. For this purpose, production employees hang the parts on specially developed coating devices. Now the parts travel upwards. There, they are cleaned of grease and dirt and coated with a conversion layer that serves as corrosion protection or adhesion promoter. After pretreatment, the guide rails are rinsed and dried to ensure optimum surface cleanliness.

Now the conveyor belt transports the substrates to the heart of the powder application system, the coating unit. Here, the fully automated application of the powder coating takes place. Guns coat both sides of the component; the A-side of the guide rail is applied with the powder coating separately to the B-side. The intelligent gap control recognizes the beginning and end of the hangers. On these component-free gaps, the guns switch off automatically. This saves powder. Excess powder is fed back into the circuit.

High challenge in the coating process

The requirement in this automated coating process is in the rear, averted area of the guide rail. Here, it is important to achieve the same coating thickness as possible as on the front side of the component. "The guide rails are very small, complex parts with a wide variety of geometries. In addition, we are limited in terms of coating thickness upwards and downwards," says Martin Kolenda, describing the challenges of the contract order. "The tolerance band of 40 to 120 μm looks quite comfortable at first glance, but the pitfall is in the details: because the front and back of the guide rails must have approximately the same coating thickness." If too much powder is applied to the guide rails and the coating thickness is thus outside the tolerance band, the passenger car windows will later jam when opened. "This is because the mechanism can no longer move the window pane upward. And in the worst case, the electric motor of the window regulator breaks down because it would simply need too much force to move the jammed window," the quality manager knows.

But that's not enough of the challenges: Metob processes numerous different pairs of rails, which also have completely different geometries. Added to this are variable, external influences such as humidity or temperature, which also affect the coating. In order to compensate for the disruptive external influences, the parameters of the coating plant can be adjusted, but the coating of the guide rails remains an extremely fragile process. The plant coats a high number of such guide rails per day. With the previous testing equipment, the coating thickness was measured after baking, i.e. very late in the process. "If it then turned out that the coating thickness was not correct, the entire line was a loss after application. This is because the parameters set in the system apply to the entire batch. A large quantity would be miscoated and would have to be disposed of at high cost," Jobst calculates.

In order to optimize the process settings and process control, the group of companies now relies on coating thickness measurement even before the powder coating is baked. The Metob managing director had become aware of the in-process coating thickness test through the OptiSense user report in a trade journal. "Non-contact before baking sounded very exciting", Marco Jobst remembers, "I then simply called OptiSense".

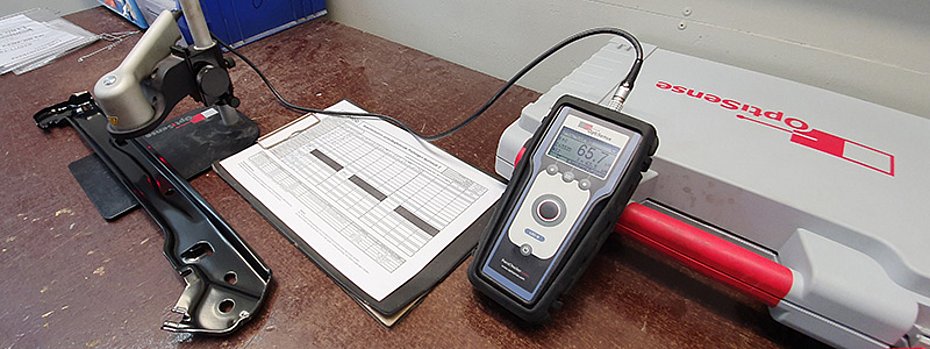

PaintChecker passes trial period

OptiSense employee Sascha Schmidt demonstrated the PaintChecker Mobile coating thickness testing system fluchs. Subsequently, the hand-held measuring device was put through its paces by Metob employees during ongoing operation for a quarter of a year and compared with the measured values of the contact-based devices after curing. "Ultimately, we wanted to know: Is the system set up economically? Because that's the only way we can avoid complaints and faulty coatings," is how quality manager Kolenda sums it up.

Of course, Metob also looked around at competitors in terms of measuring technology. "The devices certainly have their justification - but they were not very suitable for us. The measuring spot of the devices was too large and thus the measured values were not as accurate as we would have liked. That's why OptiSense won the race," says Kolenda, summing up the decision in favor of PaintChecker Mobile. The company initially ordered two of the mobile measuring devices.

The early measurement saves incorrect coatings

Now, a coater from the production team checks the coating thickness in each case directly behind the coating booth, if the powder coating has not yet been baked. If the coating is out of tolerance, it is now possible to react much faster and correct the system setting. Testing is carried out for each guide rail at six "neuralgic" points, which are marked accordingly. For this purpose, an employee removes the rail from the production process. He measures the layer thickness and documents it in order to compare the target and actual values. The final results are documented and archived.

Control measurements of the layer thickness are carried out every 15 minutes. Metob relies on an extremely intensive series-accompanying inspection, in which coating thickness and gloss level are measured at closely timed intervals, and adhesion tests (cross-cut) are carried out. "We are under a lot of pressure these days in terms of verification requirements. This is due to the special requirements of the different orders. Depending on the customer, there are also other requirements such as tensile shear testing, arc testing, as well as peel testing and corrosion testing. We carry out all these tests in-house and finally archive the test reports. We also store reserve samples for possible later comparison," Jobst explains the necessity of complete documentation.

Stable processes through intensive testing during series production

"Since we have been using the PaintChecker Mobile, our processes have become much more stable," confirms Martin Kolenda. "Previously, we could only measure the coating thickness after baking; with non-contact testing before baking, the fluctuation amplitudes are much lower." In the meantime, the tolerance band of the coating thickness could be harmonized. And the equalization of the coating thickness values of the front and reverse sides has also been achieved. The values now differ by only a few μm and there are hardly any outliers. The process runs more evenly and better."

The new test procedure pays off

The new test method pays off Sustainable production is written in big green letters at Metob - and not just when it comes to solvent-free coatings. After all, it is an energy-intensive company with electricity consumption of around 4 million kWh and gas consumption of around 14 million kWh per year. Metob has long since achieved the energy turnaround: in 2016, a combined heat and power plant was put into operation. In 2020, the photovoltaic system was launched, which is currently being expanded and is already making a significant contribution to reducing CO₂ emissions. Since 2020, the company has been feeding its electricity consumption entirely from renewable energies. In 2021, an offset project for natural gas was initiated. "By using green power products, we are already climate-neutral in Scope 2 - these are emissions from the use of energy that we purchase," Marco Jobst is pleased to report. In the meantime, the Group has also commissioned an energy consultant to conduct an audit to identify further savings potential. Metob also gives preference to environmentally friendly solutions from sustainable partners when it comes to its suppliers.

"Thanks to the new coating thickness gauge, we know much faster whether our coating is in order or not. And every part we don't have to dispose of today means less equipment load, energy consumption, resource use and material loss. So we're saving raw materials and energy at the same time with PaintChecker Mobile." Incidentally, Metob has since purchased two more PaintChecker Mobile units for its plant in Hildburghausen (Thuringia). The bottom line is now fourfold optimization in terms of resource efficiency thanks to OptiSense. (OM-05/23)

Contact

OptiSense GmbH & Co. KG

Annabergstraße 120

45721 Haltern am See (Germany)

Tel. +49 23 64 50 882-0

info@optisense.com

www.optisense.com

OptiSense

OptiSense is the world's leading supplier of photothermal measurement systems for coating thickness on a wide range of substrates. The OptiSense portfolio consists of industrial inspection systems for non-contact automated coating thickness testing in industrial plants, mobile measuring devices for non-contact coating thickness testing, and services.