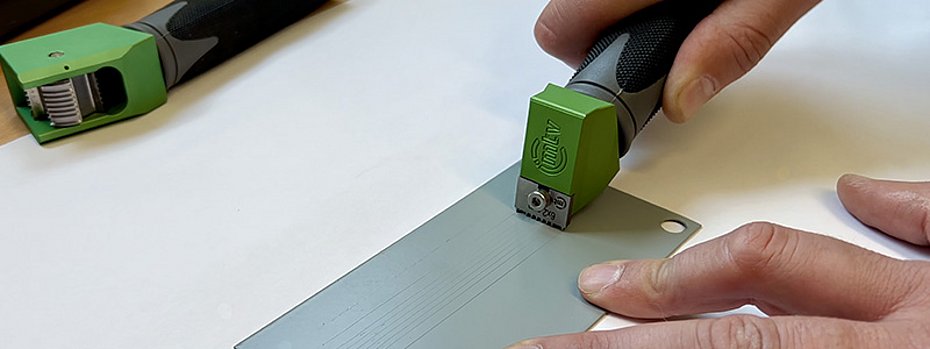

Adhesion testing of coatings made easy: mtv Messtechnik has thoroughly revised the cross-cut testers of the CC 1000 and CC 3000 series. Depending on the version, the now green anodized handheld testers completely or partially cover all common cut distances between 0 and-250 µm. At the same time, they are suitable for any substrate. The spectrum ranges from metal to plastic and glass to wood. Both device series from mtv Messtechnik cover all relevant cross-cutting standards (DIN EN ISO 2409, ASTM D 3359, DAIMLER DBL 5416/7384). Their unique selling point on the market results from their movable cutting head and from the automatic reset. The cross cutters of the CC 1000 series have only one cutting edge, those of the CC 3000 product line have circular knives with up to eight cutting edges.

Cross cut for testing the adhesion

The cross-cut test according to DIN EN ISO 2409 and ASTM D 3359 can be used to test the adhesion of coatings and painted surfaces up to a maximum layer thickness of 250 µm. The destructive test method is used in a wide range of industrial sectors, because the adhesion of coatings is a decisive product and quality characteristic for their protective effect. For this purpose, the materials tester makes six parallel scribe cuts and six additional "cross cuts" at right angles on the coating to be evaluated. Depending on the coating thickness, the distance between the individual cuts can be one to three millimeters. In this way, a uniform pattern - a grid - of 25 squares is created. Once the cross-cut has been made, loose particles are removed from the cuts using a brush, adhesive tape, compressed air or nitrogen, and the result is evaluated. A distinction is made between cross-cut characteristic values from 0 (very good) to 5 (very poor), abbreviated Gt 0 to Gt 5.

Cross cut tester with many accessories and practical features

mtv Messtechnik has trimmed both the CC 1000 and CC 3000 series for ergonomics and easy handling. Thus, all of the company's cross-cut testers are equipped with an automatic reset. The practical carrying case in which they are delivered also contains, in addition to the respective device, an illuminated magnifying glass, medium-hard brush depending on the model version, and an Allen key. The latter is used to change the cutting tool. It is recommended to replace the cutting edge after 200 to 500 grid cuts - depending on the hardness of the substrate.

In addition to the CC 1000 and CC 3000 series, mtv Messtechnik has testers in its program that are optimally designed for curved surfaces with their flexible, individually mounted blades. The Erftstadt-based manufacturer markets these as the CC 5000 series. In addition, it offers custom-configured stationary and motor-driven devices that are mounted on a turntable or guided by a mechtronic, for example. Customers can also obtain additional accessories and spare parts, such as cutting knives, from mtv Messtechnik for the aforementioned product lines. (OM-07/23)

Contact

mtv Messtechnik oHG

Justus-von-Liebig-Straße 17a

50374 Erftstadt-Gymnich (Germany)

Phone: +49 2235 987170

E-Mail: info@mtv-messtechnik.de

www.mtv-messtechnik.de

About mtv measurement

mtv Messtechnik oHG was originally founded purely as a sales organization for measuring and testing equipment used in paint production and processing and in corrosion protection inspection. Since 1994, the company, located in Erftstadt near Cologne, has been an authorized dealer for the measuring instruments of the U.S. manufacturer DeFelsko. At the same time, the company started developing and producing special test equipment for quality control in surface technology, which is marketed under its own name.