25 years of OptiSense coating thickness measurement - Interview with Managing Director Dr. Jens Heymans

On the occasion of OptiSense's anniversary, Managing Director Dr. Jens Heymans briefly reviews the company's history and provides an insight into topics and technologies that are currently occupying the supplier of thickness gauges and its customers.

OptiSense turns 25 years young and is thus in its prime. If you look back to the foundation in 1998, you can be amazed: About how quickly innovations enter the portfolio of the Haltern-based manufacturer. Today, OptiSense is the market leader in non-contact coating thickness measurement. Was that foreseeable 25 years ago?

Dr. Jens Heymans: "In addition to the numerous innovations, what sets us apart is our ability to deal flexibly with new technical requirements. Our recipe for success is: You have to be visionary every day! Another building block of success are the long-standing customer relationships. OptiSense counts a good 85 percent of existing customers, whom we have been accompanying on their way for many years. The same applies to our team. Many colleagues have been on board for a long time."

Dr. Jens Heymans: "Oh, there are quite a few milestones: Starting with the foundation as a spinoff of the Fraunhofer Optics Center in 1998. Just one year later, we developed the first photothermal layer thickness sensor for a robotic industrial application. Shortly thereafter, the first major automotive manufacturers such as Audi came to us as customers. Subsequently, the patented handheld measuring device PaintChecker Mobile LED went into series production. Then in 2016, we entered the Chinese automotive market. Two years later, our industrial controller was created, which measures the coating thickness at up to eight points simultaneously.

In 2020, we launched our service suite - a comprehensive, cost-effective and proactive support service that ensures smooth and safe operation of coating thickness measurement systems. An important aspect of the suite is predictive maintenance. Predictive maintenance provides reliable measured values as a data basis for evaluation systems. This enables customers to save costs through optimized maintenance intervals and increase efficiency in planning."

Dr. Jens Heymans: "Working for global players and hidden champions means not slackening off and thinking ahead. Accordingly, we responded early on to requirements and wishes relating to automation and miniaturization. Our sensors now fit into any production environment, no matter how cramped. A large percentage of quality controls are now fast, automated inline measurements. And for this, it is more important than ever to develop correspondingly powerful measuring systems."

Dr. Jens Heymans: "Looking back, we can say that the great commitment of our employees has made us stronger as a company than ever before: In the last three years, we have grown by an average of 26 percent. And never before have we been so broadly positioned in terms of the markets we cover. We have a good mix of young and experienced employees. Developments in the market demand a different way of thinking and approaching things. Topics such as advancing digitalization, for example, have required many new ways of working. Idea development and implementation go together more quickly than in the past and can be tested for suitability in early phases. Nothing is set in stone; we want to test and try out ideas.

Ultimately, the entire company has to keep reinventing itself. Because we want to continue to be an attractive employer where it's fun to work in a team and let innovations in coating thickness measurement emerge."

Dr. Jens Heymans: "From my point of view, the continuous increase in efficiency through automation will occupy us intensively. Increasingly higher speeds and precision in the line will also demand specifications from the sensors in the future that are many times more demanding in order to measure coating thicknesses even faster in motion or also to inspect extremely thin coatings.

We will continue to deal with topics such as analytics, platforms and IIoT: Analytics, or data analysis, now counts as the foundation of modern leadership and is one of the most important skills for managing a coatings company profitably. But only a fraction of companies fully evaluate the data they collect. Yet it is precisely the know-how of the analyzed correlations that can provide important information on an optimal and truly smooth-running coating process."

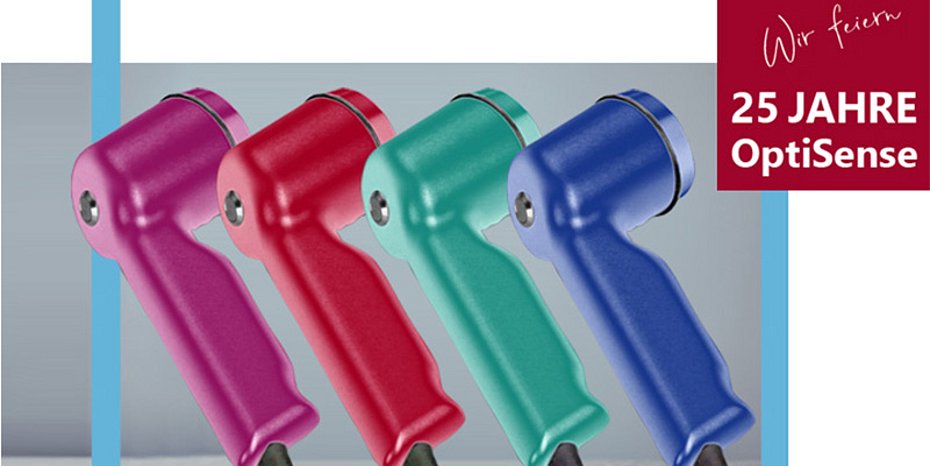

Dr. Jens Heymans: "For our 25th anniversary, we are launching a strictly limited product design. With this limited edition, we are underlining the premium concept of our brand down to the smallest detail. We are highlighting the special look of our "PaintChecker Mobile 25 Years" with a very special polished surface finish. A novelty is that our customers and all interested parties can decide online themselves on the final look of the mobile PaintChecker model. For this purpose, there is a poll via LinkedIn, Instagram and on our homepage until March 23, 2023. And everyone who takes part can, with a bit of luck, win one of the hot prizes with a total value of over 5,000 euros."

Dr. Jens Heymans: "I would like our entire team to remain so motivated! For the future, I wish us a lot of interest in new things and, of course, continued exciting projects and great customers. If it's fun and everyone is enthusiastic about what they're doing, OptiSense will continue to be on a very good path." (OM-1/23)

Online survey

Customers and interested parties can decide on the final appearance of the mobile PaintChecker model via an online survey.

Contact

OptiSense GmbH & Co. KG

Annabergstraße 120

45721 Haltern am See (Germany)

Tel. +49 23 64 50 882-0

info@optisense.com

www.optisense.com

OptiSense

OptiSense is the world's leading supplier of photothermal measurement systems for coating thickness on a wide range of substrates. The OptiSense portfolio consists of industrial inspection systems for non-contact automated coating thickness testing in industrial plants, mobile measuring devices for non-contact coating thickness testing, and services.