Lach Diamant: 25 years of safety for tool machining EDM machines

To reduce the risk of fire in EDM machines for PCD tool processing, Lach Diamant introduced a fire warning system 25 years ago. This has been expanded over the years and has provided protection against fires ever since.

EDM machines always harbor a fire risk. The erosion process produces a spark that is protected from oxygen by a dielectric - usually oil-based. If oxygen nevertheless reaches the spark, a fire can break out. In practice, the dielectric is supplied via adjustable hoses. If these are not carefully adjusted by the machine operator, the risk of fire increases considerably. However, other factors - such as unsuitable electrodes or incorrect process settings - can also trigger a fire. This is why EDM machines are now fully encapsulated and equipped with fire extinguishing systems as standard. Nevertheless, even short fires can cause major damage: Cables, motors, measuring systems or bellows are damaged, processes are interrupted and machines break down. Even if the extinguishing system reacts in time, the fire extinguisher has to be replaced after use - which inevitably means downtime.

Safety concept for EDM machines for PCD tool processing

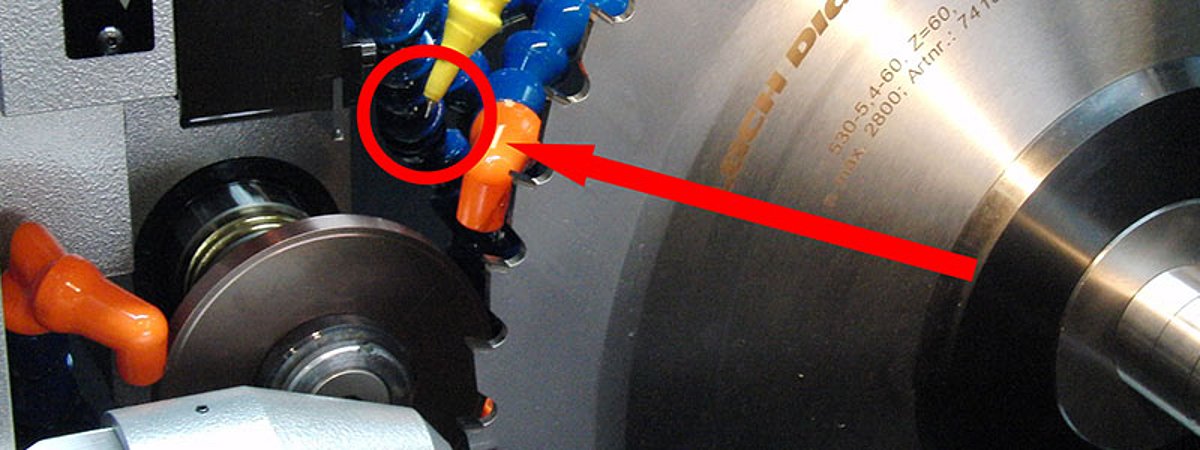

To prevent this from happening, Lach Diamant developed an innovative fire warning system for all EDM machines for PCD tool processing in 1999. The heart of the system is an extremely fast-reacting temperature sensor positioned directly above the spark. If it detects a fire, it immediately switches off the generator and dielectric supply, stops the eroding process and informs the operator. The fire's breath is literally taken away - in nine out of ten cases it goes out immediately. In most cases, it is sufficient for the operator to correct the position of a hose. The process can then be continued without restarting the machine - zero downtime. Should the fire nevertheless continue, an independent CO₂ extinguishing system takes over. In 2000, Lach Diamant went one step further: a multi-stage sensor system was introduced. In addition to the temperature sensor, an infrared camera now monitors the entire machine room. The system switches off all units in the first step - and only activates the CO₂ extinguishing system in the second step. Today - 25 years later - Lach Diamant supplies every EDM machine for PCD processing with this triple safety concept as standard. The result: since its introduction, no customer who has installed and activated this system has suffered serious fire damage. On the contrary, the fire warning system has nipped small fires in the bud in thousands of cases without the CO₂ extinguishing system having to intervene. This has not only avoided costs and downtime, but also saved countless tons of CO₂ emissions.