Elpeguard SL 1800 FLZ electronic protective coating from Peters defies extreme frost

The Elpeguard SL 1800 FLZ impresses with its temperature flexibility, especially in cold conditions. The new product from Peters Research exceeds the industrial standard for cold-flexible acrylates by as much as 25 degrees. In other words, the protective coating does not show any negative effects even in the case of temperature shocks from +125 °C to -65 °C.

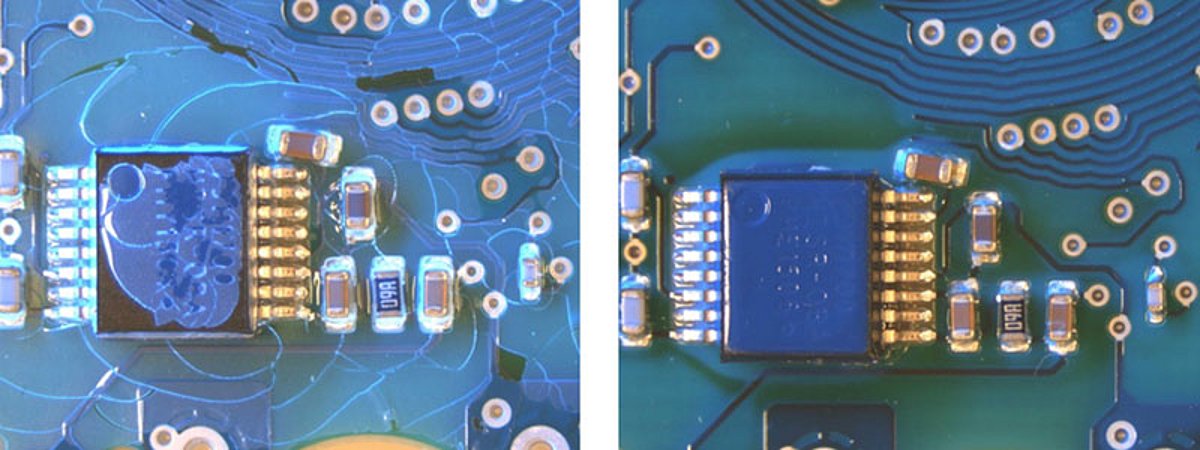

"For the automotive and aerospace sectors, it is now necessary to push beyond the low point of -40 °C into even more extreme frost layers. Our Elpeguard coating can meet this requirement from the said industries," says Stefan Schröder. The Global Product Manager Conformal Coating refers to long-term tests in Peters' climate laboratory. There, the VT³ 7012 S2 thermal shock system is a test chamber of the latest generation in which electronic components and printed circuit boards are subjected to multiple rapid temperature changes in ranges between -80 °C and +220 °C. After this successfully completed test phase, graduate engineer Stefan Schröder emphasizes that with the SL 1800 FLZ, the further development of the Peters classic from the Elpeguard 1307 protective coating family can be described as successful. With the Elpeguard product SL 1800 FLZ, the highly specialized research and development team in Kempen has once again come up with a solution that is both forward-looking and practice-oriented. "The newcomer has even better end properties," says Stefan Schröder.

The modified acrylate is thus the measure of all things in the family of physically drying thin-film coatings on the world market. According to the company, in addition to its high thermal shock resistance, the Peters coating is also characterized by good wetting of silicone-contaminated surfaces with the Elpeguard protective coatings of the SL 1801 FLZ series. According to Stefan Schröder, what makes the difference and the icing on the cake for the relevant industries to choose Elpeguard SL 1800 FLZ is its extreme resistance even at the lowest temperatures. In the automotive industry, for example, it is important to remember that vehicles must be reliably operational even in regions with continuous frost below -40 °C. In space, the printed circuit boards and their coatings are exposed to even more extreme temperatures. According to Stefan Schröder, this kind of frost could be dangerous for conventional acrylates, as hairline cracks could lead to moisture penetration and, in the worst case, to failure of the electronics. With Elpeguard SL 1800 FLZ, however, there is no risk of dendrites forming even under difficult environmental conditions, provided that the material is processed properly.