Excelitas at K 2025: Noblelight solutions for plastics processing

Excelitas is presenting Noblelight solutions for plastics processing at the K 2025 trade fair. Infrared emitters that are precisely matched to the product and process in terms of shape, voltage and power, as well as UV technology for curing.

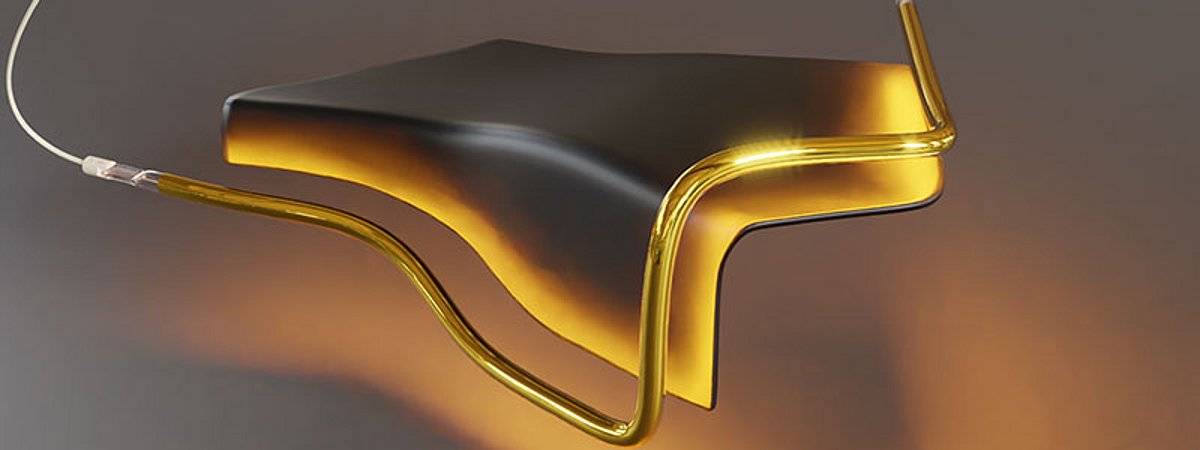

Infrared systems solve many challenges in plastics processing, as Excelitas will be demonstrating at the K trade fair in Düsseldorf (October 8 - 15, 2025). Deburring glove compartments, laminating interior trims or welding pipes for ventilation systems - all of these are involved in plastics processing in modern cars. Heating processes are often required at challenging corners, edges and borders. Infrared contour emitters are shaped precisely along these contours, which brings decisive advantages. Heat is applied precisely to the burr or edge, which minimizes energy consumption and optimizes the production step. "This automates a complex process with reproducible results," says application specialist Michael Jauch, "We know customers who have now carried out more than half a million deburring cycles with the same set of emitters!"

Deburr faster with infrared radiation

Plastic handles, covers and trims are often manufactured using injection molding. The formation of sharp-edged burrs, for example at the mold parting line, cannot always be prevented. Removing burrs before further processing or coating can be a real challenge, especially for parts with complex shapes. Manual deburring with gas flames or special tools does not deliver uniformly reproducible results. Infrared radiation heats plastic parts without contact and in a matter of seconds in a targeted manner on the surface. Shaped emitters direct infrared radiation exactly where it is needed. This is made possible by reflectors that are applied directly to the molded emitters as a coating. The light emission gap is selected so that the energy arrives precisely at a ridge. This enables in-line production of plastic parts and the reject rate in the production of molded parts can be significantly reduced.

Infrared heat for efficient energy use

Infrared heating technology works by transmitting electromagnetic waves, which then generate heat in the product. This requires neither direct contact with the material nor a transfer medium such as gas or air. Infrared emitters transfer energy into a plastic product and generate heat exactly where it is needed. Infrared systems with contour emitters can be optimally networked with robots or handling systems. The ability to switch infrared emitters on or off in a matter of seconds means that energy is used efficiently, time is saved and, ultimately, production costs are reduced.