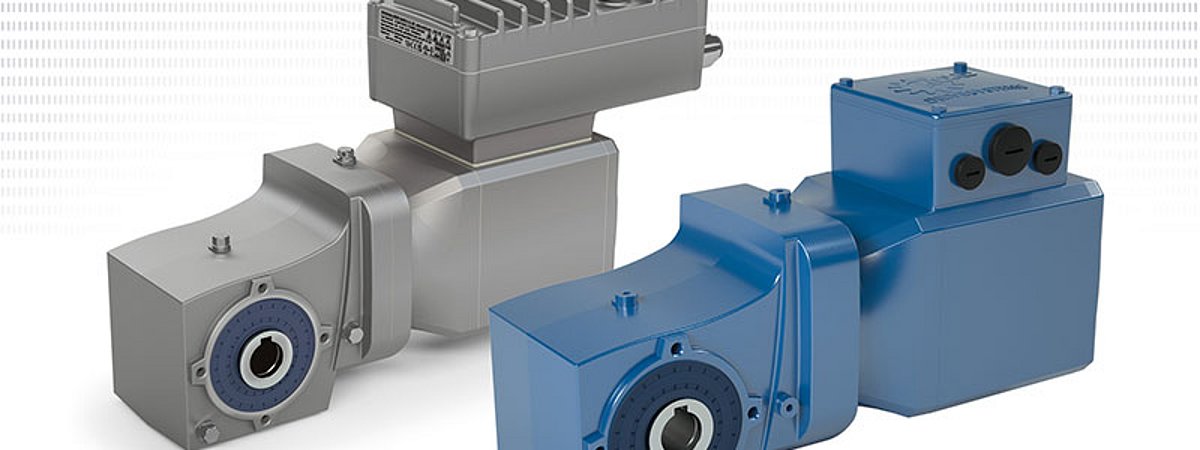

Nord Drivesystems with new surface protection solutions

With NXD, Nord Drivesystems has launched the latest generation of its surface treatment onto the market. The system manufacturer equips its aluminum drive solutions with effective corrosion-resistant surface protection in two versions.

NXD is Nord's surface treatment for gearboxes, smooth motors and frequency inverters made of aluminum. It offers users an economical and effective alternative for the surface protection of drive solutions that are subject to extreme environmental conditions. With NXD, Nord increases the durability of these drive systems and thus extends system availability. The surfaces are chromate and PFAS-free. With NXD, aluminium surfaces are galvanized, making them particularly corrosion-resistant and durable.

Surface and corrosion protection in two versions

The latest generation of surface finishing is available in two versions. NXD Basic consists of the electroplated base layer, which is supplemented by a layer of paint. The corrosion protection is retained even if the paint is damaged. This variant is suitable for use in demanding environmental conditions, for example in the offshore sector. The second variant is the food-safe NXD tupH. Here, the galvanic base layer is sealed with a sealer. This process prevents flaking or microcracks that are susceptible to germs. NXD tupH offers reliable surface protection, especially for the extreme conditions in wash-down applications. This makes drive solutions resistant to acids and alkalis used in regular cleaning and disinfection processes. As the sealing of the galvanized base layer prevents particles from coming off even if the surface is damaged, NXD tupH surfaces are also hygiene-friendly and can therefore also be used in hygiene-critical industries. NXD tupH complies with FDA food regulations and EU Regulation 1935/2004, meaning that components with NXD tupH surfaces can be used in practically all major markets worldwide for processing hygiene-sensitive products.

Aluminum offers numerous advantages

With NXD, Nord is tapping into the advantages of aluminum as a material for demanding environments and hygiene-sensitive production areas. Aluminum is lightweight, cost-effective and fully recyclable. Aluminum enclosures also offer better thermal conductivity, which reduces their maximum surface temperature. NXD is available for all Nord drive components made of aluminum, including the DuoDrive integrated geared motor system, the energy-efficient IE5+ smooth motors as well as NordBLOC.1 helical gearboxes and NordBLOC.1 bevel gearboxes. The NordAC On Pure, a decentralized frequency inverter with an NXD tupH interface, will also be available soon. This enables the solution provider to supply complete drive systems with food-compliant surface finishing from a single source.