Plantag Coatings welcomes prospective master carpenters and wood technicians

In spring, the master craftsman and technician class of the Felix-Fechenbach-Berufskolleg with 16 prospective master carpenters and wood technicians visited the technical center of Plantag Coatings GmbH in Detmold. They were provided with information and knowledge on the subject of coating technology.

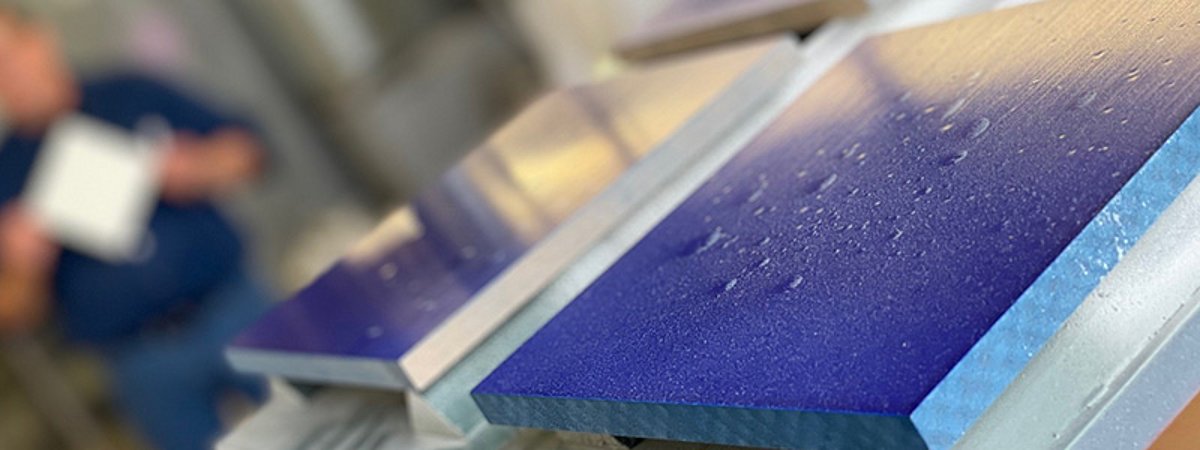

Founded in 1893, the private "Tischler-Fachschule Detmold" and later technical school for woodworking and interior design is one of the best-known training centers in the woodworking sector in Germany and abroad. Plantag Coatings has long supported practical training and imparts valuable knowledge about manual and industrial painting processes in the Plantag Technical Center. During the visit of the master craftsman and technician class to Plantag Coatings, a theoretical block first provided information on the subject of manual coating application and typical coating errors. Martin Schulz, head of the technical center, addressed topics such as gun technology and air supply, and explained the relationship between hose diameter and spray pressure. In addition, the problem of painting large areas without streaks, which occurs time and again in everyday work, was dealt with. Other problems and their pragmatic solutions were also discussed. In the practical part, the participants went directly into the paint booth to demonstrate an unusual paint structure. There, under the guidance of technical center employee Robert Schulze, impressive sample surfaces were painted with a "water drop effect".

Finally, Sarito Wolsiffer from Plantag Product Management gave a brief insight into the technical center and the machinery there. Here, the focus was on the topic of industrial wood varnishing. Among other things, the operation of sanding machines and automatic surface spraying machines was presented and there was an insight into roller varnishing including the use of the spatula unit. The special features and advantages of UV curing and The special features and advantages of UV curing and the use of excimer technology were also on the agenda. Here, the technology was explained how different surface effects (soft touch, matte surfaces, glossy surfaces) can be created with a coating by means of excimer curing in an inert atmosphere.