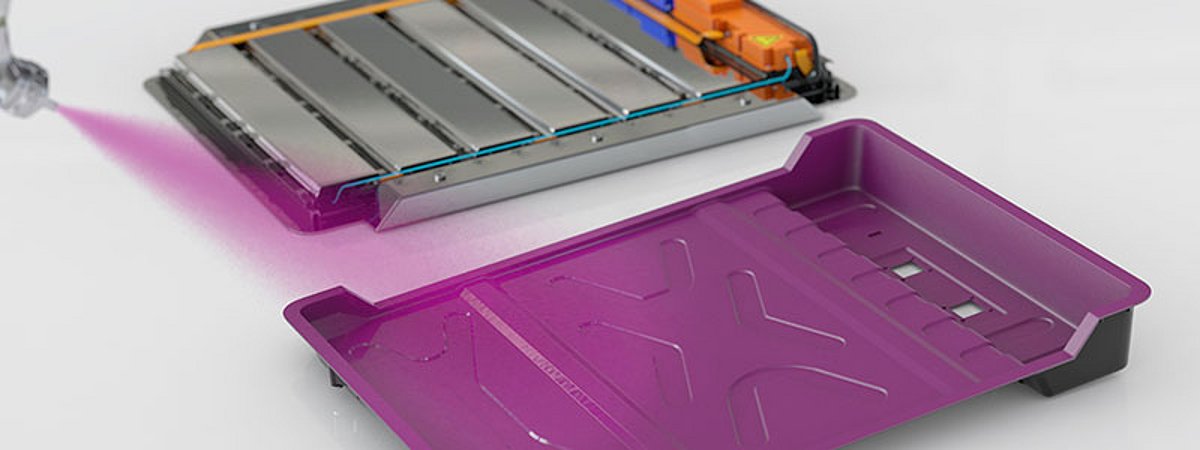

Evonik: Tego Therm fire protection coating for battery housings

With its Tego Therm product portfolio, Evonik is opening up applications in heat-resistant and fire-retardant coatings for battery housings in electric vehicles. The excellent thermal insulation and fire resistance inhibit the spread of fire in batteries.

In the growing market for electric vehicles, safety standards for lithium-ion batteries are becoming increasingly stringent. This is precisely where coatings based on Tego Therm products offer a high-performance solution for effective heat and fire protection coatings, which are essential in electric vehicle batteries. "The safety of lithium-ion batteries in electric vehicles is becoming increasingly important," says Dr. Benjamin Schaeffner, head of the Industrial & Transportation Coatings market segment at Evonik Coating Additives. "With our Tego Therm products, we deliver reliable products that not only meet current safety standards, but exceed them." The Tego Therm portfolio includes products that have been specially developed to improve heat-resistant and flame-retardant coatings. Tego Therm HPG 4000, a granulate with a core of microporous silica, provides exceptionally low thermal conductivity, high hydrophobic properties and low flammability. Tego Therm HPG 6806, a finer silica-based granulate, not only has excellent insulating properties, but also improves mechanical resistance and ensures smooth, even coating surfaces. The aqueous polysiloxane hybrid binder Tego Therm L 300 also improves thermal stability and is crucial for the flame retardancy of protective coatings.

Enclosures coated with Tego Therm meet the UL 94 V-0 fire protection standard, which classifies the flammability of plastics. This means a new, higher level of protection for batteries in electric vehicles. In addition, the simple spray application of the coating enables comprehensive and efficient protection, even for complex three-dimensional surfaces. "The bond between the Tego Therm binder and the granules is at the heart of our solution. It minimizes heat transfer and thus effectively inhibits the possible spread of fire, which provides crucial additional time for emergency measures in the event of a fire," says Dr. Niko Haberkorn, Global Head of Business Development for the Industrial & Transportation Coatings market segment at Evonik Coating Additives. "Our Tego Therm products ensure high mechanical resistance so that the coated components can also withstand high temperatures." Tests confirm the safety aspect: When exposed to a propylene flame with a temperature of over 1,000 °C, coatings based on Tego Therm binders and granulates effectively protect the substrate. The temperature on the back of the coated substrate remains moderate despite the low film thickness.