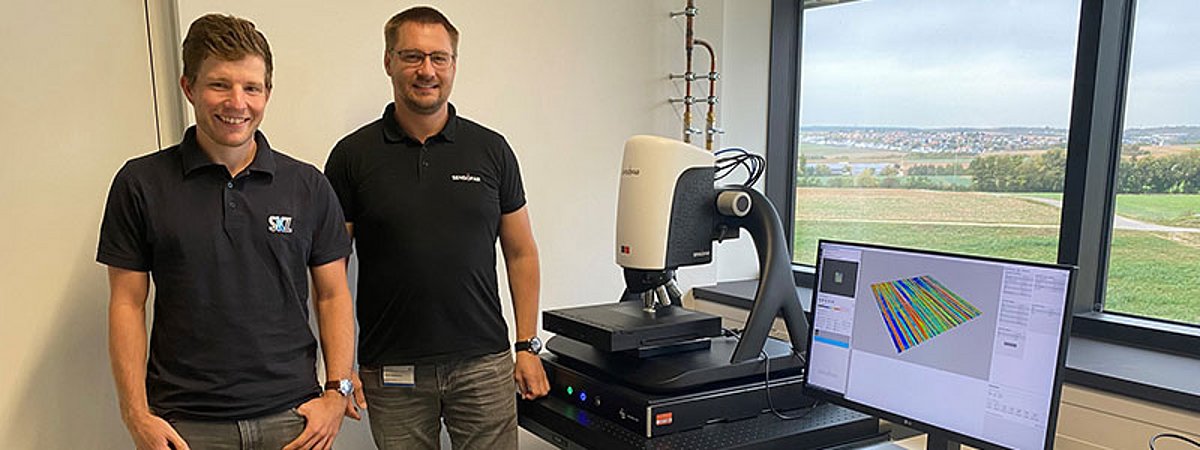

SKZ receives 3D profilometer for surface measurement

The SKZ Plastics Center has a new non-contact measuring device for topography and surface roughness: The optical 3D profilometer type S Neox enables measurements by means of confocal microscopy, focus variation and white light inferometry, whereby both ultra-smooth and rough structured surfaces can be precisely analyzed.

Optical profilometers are used for the non-contact characterization of surfaces with regard to topography and surface roughness. The optical 3D profilometer type S Neox from Sensofar is now available at the SKZ for future surface analyses. This can be used, for example, to evaluate the surface of plastic parts that are used as visible parts in the automotive sector. Surface roughness in accordance with DIN EN ISO 25178 (3D roughness) or DIN EN ISO 21920 (2D roughness) is also of great importance in day-to-day business and can also be determined using the optical profilometer. The S-Neox includes a motorized tip-tilt table and a nosepiece to cover a wide range of different surface topographies. The sensor head features focus variation, confocal microscopy and white light interferometry modes. Depending on the operating mode and objective, the high vertical resolution of the profilometer enables imaging down to the single-digit nanometer range. Steep edges can be measured up to an angle of 86°, depending on the structuring of the surface. Comprehensive evaluation software rounds off the measuring system. This can be used, for example, to demonstrate an automated comparison of roughness parameters with process-relevant statistics in SKZ training courses.

"Our focus at SKZ is clearly on practical learning. That is why we attach great importance to good equipment that reflects the state of the art. This allows participants in our courses to apply the knowledge they have acquired directly in the company and bring new ideas back to industry," explains Matthias Ruff, Sales Manager Education and Research at SKZ. At the Plastics Center, the optical profilometer is part of the equipment for a whole range of different courses on quality assurance. The subject areas include automotive, medicine, packaging and quality assurance methodology for various plastics processing methods.