Micro-Epsilon: High-precision surface measurement of technical mirrors

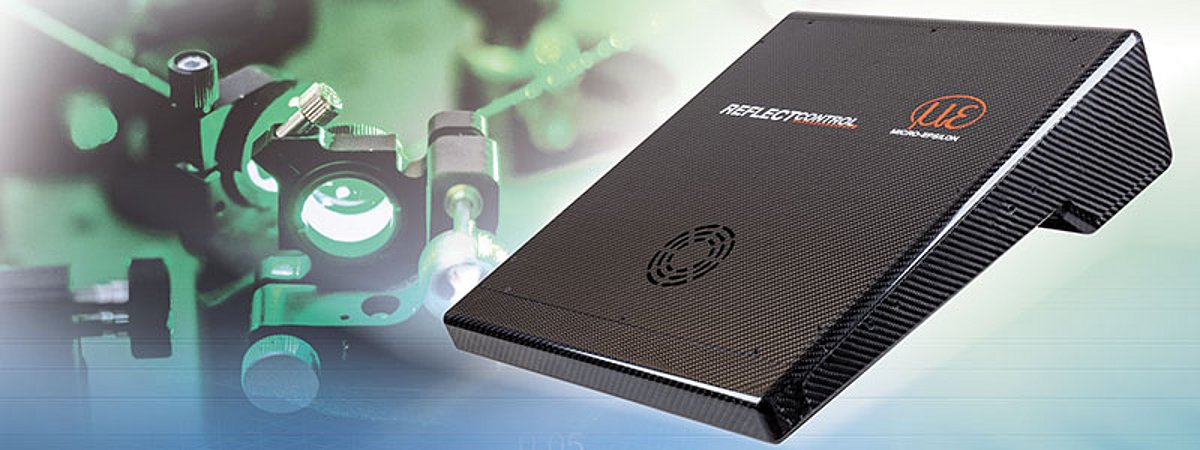

The surface characterization of technical mirrors is of essential importance for many manufacturers. With the ReflectControl sensor system from Micro-Epsilon, automated surface inspection of reflective or shiny objects can be carried out with consistently high quality.

Measuring technical mirrors is a constant challenge in the optics industry. When high-precision 3D measurements are required on reflective and shiny components, the ReflectControl sensor from Micro-Epsilon is used. This technology is particularly impressive for flat surfaces thanks to its high measurement rates with nanometer accuracy. The results are output in the form of 2D images and a 3D point cloud.

The ReflectControl sensor records the surface of technical mirrors with up to five million data points, allowing the measurement object to be precisely reconstructed. This allows numerous surface deformations to be identified. Depressions such as scratches, dents, notches etc., but also elevations such as pimples, grains and beads can be visualized. All effects that change the reflectivity of the surface are displayed in the amplitude image. Classic examples of this would be fingerprints or other soiling. The 3D sensor uses the principle of phase-measuring deflectometry. It is characterized in particular by its extremely high z-resolution in the nanometer range. In combination with its large measuring range of around 170 mm x 160 mm, up to five million data points of the surface to be measured can be captured within a few seconds.