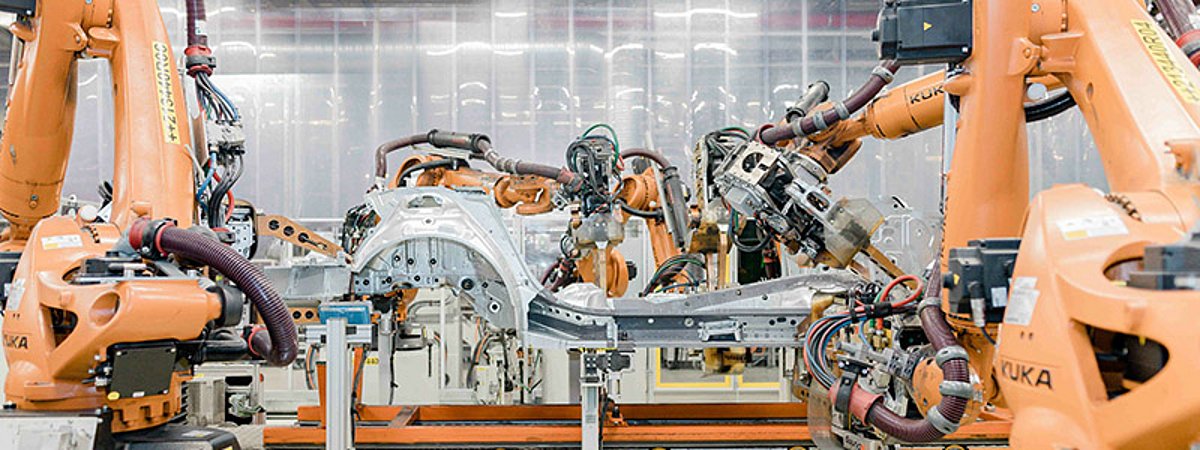

Audi launches AI for quality control of spot welds

Audi is pushing ahead with the digitization of its production: Following a successful pilot project, the carmaker is starting to roll out an artificial intelligence (AI) system for quality control of spot welds in body construction. The AI was previously developed and tested at the Neckarsulm site.

With the help of artificial intelligence, Audi analyzes around 1.5 million spot welds from 300 vehicles per shift at its Neckarsulm site. By way of comparison: Until now, employees in production have been monitoring the quality of the processes in resistance spot welding (WPS) manually on a random basis using ultrasound - and thus checking the slightly more than 5,000 spot welds of a vehicle. By using AI, employees can now focus on possible anomalies and thus control quality even more efficiently and in a more targeted manner. Preparations for the application of the technology at other plants in the Volkswagen Group have already begun. For example, the technical infrastructure for AI use is currently being created at the Audi site in Brussels. Installation is also scheduled to take place this year at the Volkswagen plant in Emden and at Audi's headquarters in Ingolstadt. To set up the technical infrastructure at these sites, the team of experts is currently identifying differences in weld settings in order to retrain the AI model in this respect.

The data generated by the application can be used to optimize other processes in the future. For example, the Audi team is currently working on using the data as a basis for predictive maintenance in the future. "Digitized production lines are a foundation for Audi production of the future: as part of our '360factory' production strategy, we will make manufacturing at Audi sites worldwide even more efficient. The use of artificial intelligence in series production has very great potential in this regard," says Gerd Walker, Audi Board Member for Production and Logistics. In order to map the process in an audit- and certification-proof manner, development at the Neckarsulm site was carried out in close coordination with the German Society for Quality (DGQ), the Fraunhofer Institute for Industrial Engineering IAO and the Fraunhofer Institute for Manufacturing Engineering and Automation IPA. The background to this approach is that no standards and certifications from an independent body exist for AI applications to date. "In manufacturing, for example, this makes it possible to argue conclusively in an audit how the result of an AI-supported test comes about," explain Mathias Mayer and Andreas Rieker, WPS Analytics project managers. Together with the Fraunhofer Institutes IAO and IPA, Audi has also developed an AI guide for production.