The Acerios hot-active plasma technology from Fronius removes particulate and filmic contamination - from both metallic and non-metallic surfaces. Automobile manufacturer Audi has been using the process for thin aluminum body parts for two years now: Where the sheets have to be prepared for stud welding, Acerios has succeeded in significantly reducing the cleaning costs incurred. At the same time, resource efficiency was increased.

"In the worst case, the failure of a ground stud connection can lead to a vehicle coming to a standstill," says Dipl. Ing. Daniel Rudolph, responsible technology developer for joining and lightweight construction at Audi AG. "In Audi A8 production, we place numerous ground bolts where we have to ensure that each one is perfectly joined. To meet the quality requirement, we go to great lengths." This is because the quality of each stud weld is largely determined by the properties of the surface. Impurities from drawing oils and dry lubricants - as used in metal forming - can lead to defects in the joined joint.

Clean Flash fails due to sheet thickness

In many cases, the problem of contamination can be solved with the stud welder itself: For this purpose, a current surge (clean flash) is connected upstream of the actual welding process, which cleans the welding surface. However, this approach is no longer practical for aluminum sheets less than 2 mm thick because the heat input is too high and the sheet would burn through during the welding process. In addition, this process can result in pores, among other things, which impair the seam quality.

One such component in Audi production is the bulkhead of the Audi A8. This consists of an aluminum sheet alloy (6xxx) and is only 1.5 mm thick at those points where ground bolts are welded: "The entire component had to be chemically cleaned and pickled in a time-consuming and cost-intensive process in the first few years after the start of series production," explains Rudolph. "Only then were we able to guarantee the required 100 percent in the quality of the stud welded joint in any case."

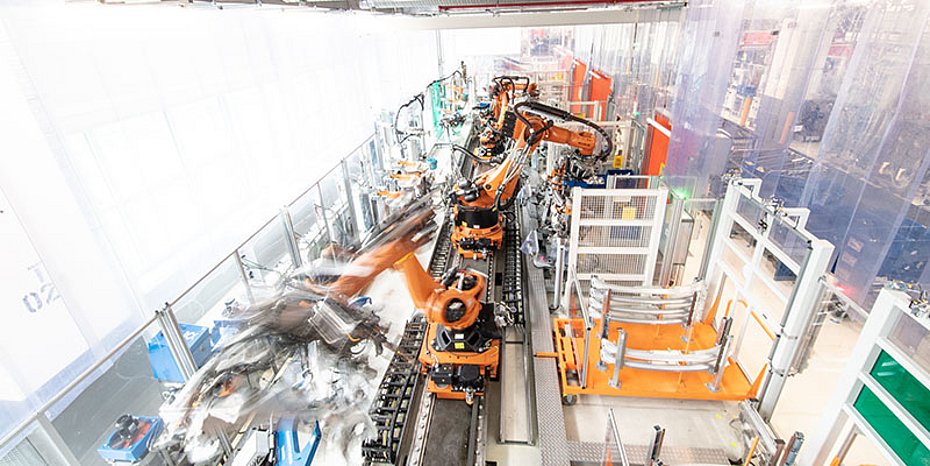

In 2017, Audi was due to set up a new production plant for what is now the fifth generation of the A8. And Audi wanted to find a remedy for the time-consuming chemical cleaning. One possible solution was seen in hot active plasma technology (HAP), which the long-standing welding technology supplier and development partner Fronius was already working on intensively. Audi had also already pursued the HAP approach with university partners.

Since Rudolph's area of responsibility also includes the evaluation of new manufacturing technologies as well as their further development until they are ready for series production, the joining technology specialists from Audi and Fronius consequently cooperated intensively. This technical approach was then jointly developed and qualified for series production. Rudolph clarifies: "Fronius was mainly responsible for the development work of the process and system technology. Application-related function tests, parameter tests, service life tests and functional tests then took place in our production department. We also dealt with the question of how the use of the technology affects further process chains such as joining, strength, paint adhesion and much more."

Partial cleaning with plasma as solution

The advantages of treating surfaces with hot active plasma (HAP) technology Acerios from Fronius are manifold. Using a stream of inert gas, the arc plasma is formed into a flame that reaches temperatures of up to 1,000° Celsius at its core. Thermal and chemical processes triggered by this ensure that material surfaces are partially and precisely freed from organic residues and filmic contamination. At the same time, the surface is activated. Since the arc in Acerios is created between the plasma nozzle and the tungsten electrode of the torch, a ground connection to the workpiece is not required. Accordingly, non-metallic materials can also be cleaned with hot active plasma.

"We tested Acerios - like all the new technologies we considered more closely - for its suitability and determined influencing variables and possible parameter windows. Together with Fronius, we then quickly optimized the prototype for series use in a targeted manner," says Rudolph. "Then our system planners and colleagues from production set about identifying a favorable installation situation."

Those responsible for the A8 line finally decided to use Acerios in a robotic cell that had enough free non-productive time to clean two areas - each with an area of 12 cm². "Therefore, the available time was even sufficient to increase the burn time of Acerios to six seconds per spot weld: As a result, the distance between the torch and the workpiece is 30 mm. And we can then lower the current to 120 A without any loss of cleaning effect," adds Jürgen Kolbenschlag, welding expert from the A8 body shop.

"This saves us wear parts," which were initially replaced by Audi after 10,000 cleaning points. It became apparent that the wear limits were far from being reached. The regular replacement was therefore continuously extended. And by the middle of 2021, the wear part limit had still not been reached - despite 25,000 cleaning points having been set.

Low integration effort

The integration of the hot-active plasma technology was facilitated by the fact that the designers could install the Acerios PCT 2000 plasma torch in a stationary position. A minimal working area within the robot's radius of action was sufficient for this. "The power supply also requires less than a square meter of floor space, so we were able to place it well outside the cell between existing supply units," Rudolph reports.

Previously unused idle time of the robot is used to transport the end wall to the torch. Accessibility to the workpiece is also very good thanks to the narrow torch, so that the plasma flame works exactly perpendicular and thus optimally aligned to the surface. There is also no need to move down lanes during the cleaning process: The cleaning effect, which starts from the inside out, completely covers the desired area within the burning time.

The fact that Acerios works with the favorable inert gas argon also suited Audi. This meant that the existing argon ring mains could be used to supply the MIG welding machines. There are therefore no further additional costs.

Audi also integrated the plasma power source, which is connected to the torch via a 6-m hose package, with ease - as Rudolph reports, "The interface of the Acerios system corresponds to that of our Fronius MIG/MAG welders. Since this is part of the VW interface specification, we were able to connect the Acerios system to the system control without any problems within one day." Setting and operation of the system are also largely based on those of the TIG power sources, as Rudolph confirms, "Anyone who can set a TIG power source can also work with the Acerios system. Operation is simple anyway, as only a few parameters such as amperage or burning time need to be set."

Manageable costs for acquisition and operation

The investments for the use of Acerios at Audi have turned out to be comparatively low. However, this has not only to do with the possibility of dual use of existing resources and various hardware. Audi's extensive experience with other Fronius power sources and their low maintenance costs was also not the only decisive factor. Compared to other partial cleaning solutions, the HAP system from Fronius is characterized by particularly low acquisition costs.

For example, in contrast to laser-based systems - which already have a basic investment of around one million euros. The Acerios configuration is many times cheaper here. Including the respective automation system, the Fronius solution is in the mid five-figure range. In addition, no separate, shielded robot cell - as required by the laser system - is necessary. Power consumption is also significantly lower than that of a cleaning laser. In addition, Acerios requires about 15 liters of gas per minute.

The savings achieved are also considerable compared to the previously common, laborious wet cleaning process, as Rudolph confirms: "We were able to reduce the cleaning costs per end wall by an amount in the lower single-digit euro range and at the same time increase resource efficiency without compromising on cleaning quality. Achieving comparable savings in vehicle construction usually involves significantly higher effort."

From the practical experience of Audi AG, it is possible to draw conclusions: Due to the low operating and acquisition costs, the use of Acerios pays off even with smaller quantities, but also in large-scale production. What's more, Fronius' HAP technology is particularly useful in confined spaces and for spot cleaning tasks in the seconds range.

Acerios expands Audi's technology portfolio

Due to these consistently good results, Audi has already integrated Fronius cleaning technology at another location: On a tunnel component, the surfaces for four stud welds are also being cleaned with HAP technology. "Acerios optimally expands the technology portfolio available to us," Rudolph concludes. "Whenever we have to weld ground studs on components with low wall thickness, this HAP technology is now immediately on the short list as a cleaning process." (OM-09/22)

Contact

Fronius Deutschland GmbH

Fronius Straße 1

36119 Neuhof-Dorfborn (Germany)

Tel. +49 (0)66 55-916 940

sales.germany@fronius.com

www.fronius.com