Plasma technology can be used to change the surface properties of a wide variety of materials in order to optimally prepare materials and material combinations for subsequent processes. As the world market leader for atmospheric plasma technology, Plasmatreat GmbH has developed various processes for this purpose: In ultra-fine cleaning of metals or glass, for example, with open-air plasma, surfaces are gently and safely freed from dust, grease, release agents and additives. This increases the surface energy and optimizes the wettability of the substrate surface. During activation, the surface of the substrate, e.g. the non-polar plastic, reacts with molecules excited by plasma. In this process, oxygen groups are introduced into the top layer of the plastic, significantly improving adhesion. This makes bonding, painting, printing or sealing easier - or, in some cases, possible in the first place. For the environmentally friendly pretreatment, plasma is applied to the substrate with pinpoint accuracy using simple compressed air through a special nozzle. One of Plasmatreat's core competencies here is the application-specific coordination of distance, treatment width and traversing speed - and the selection of the right nozzles for the process in question. Another process, PlasmaPlus technology, uses nanocoatings to create functionalized surfaces, such as an adhesion promoter layer or an anti-corrosion coating. Here, a precursor is added to the plasma jet and a nanolayer with the desired properties is then deposited.

RD2005PAD - unique rotary nozzle for flat coating

With the RD2005PAD, a rotary nozzle for coating with PlasmaPlus technology is now available for the first time. This process uses nanocoatings to create specifically functionalized surfaces that are tailor-made to meet area-specific customer requirements. The spectrum ranges from superhydrophobic, adhesion-promoting to superhydrophilic coatings. With the RD2005PAD, the first rotary nozzle with precursor feed, Plasmatreat is once again the pioneer. Until now, only static nozzles were used worldwide for this coating application, which had its focus in the selective modification of surfaces. The new nozzle, which rotates around a rotation axis, is now suitable for coating flat materials and now also offers the advantage of a particularly homogeneous treatment with high intensity in the PlasmaPlus process. This produces a reliable functional layer that enables optimum bonding, printing or painting of the coated surface.

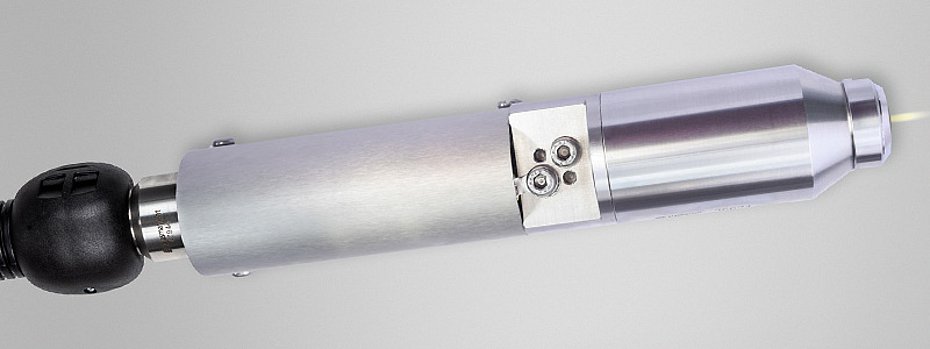

PFW10LT open-air plasma nozzle - for temperature-sensitive components

With the new PFW10LT, Plasmatreat has developed a low-temperature nozzle that also activates thermally sensitive materials and surfaces with high intensity. It is designed for use at low temperatures below 60 °C and performs a particularly gentle pretreatment of plastics before subsequent processes such as bonding. The plasma nozzle is particularly suitable for small treatment areas and contours such as boreholes or groove areas, for low-lying applications in 3D components or for medical components and products. The PFW10LT plasma nozzle is used for a treatment width of approx. 4 mm.

PFW100 open-air plasma nozzle - for flat surfaces

In order to treat flat components or surfaces at high process speeds and at the same time over a large width, the PFW100 is now available as a suitable plasma nozzle. It is particularly suitable for pretreating heat-sensitive materials such as thin plastic films or textile products such as synthetic nonwovens. It can also be used for the surface cleaning of glass or metal. The PFW100 performs uniform pretreatment over a width of 100 mm per plasma nozzle at relative speeds of up to 200 m/min. The treatment width can be flexibly varied via the modular arrangement of several nozzles. (om-2/23)

Contact

Plasmatreat GmbH

Queller Straße 76-80

33803 Steinhagen (Germany)

www.plasmatreat.com

About Plasmatreat

Plasmatreat is an international leader in the development and manufacture of atmospheric plasma systems for the pretreatment of material surfaces. Whether plastic, metal, glass or paper - the industrial use of plasma technology modifies the properties of the surface in favor of the process requirements.