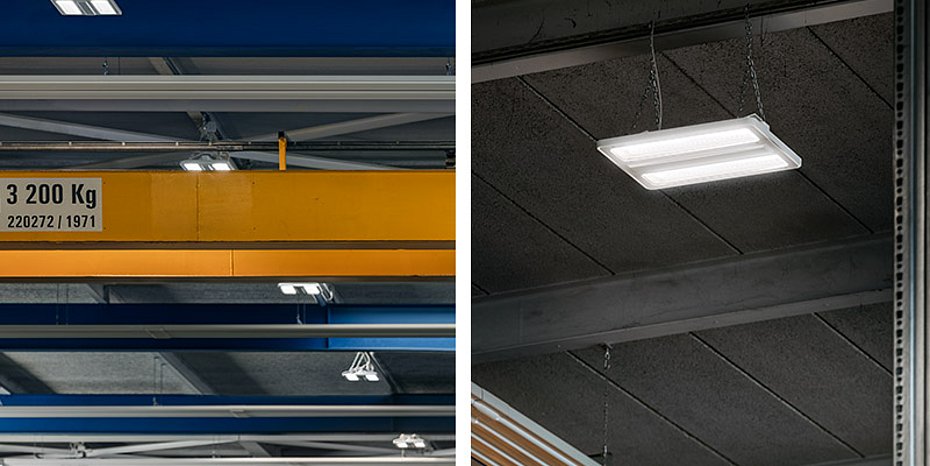

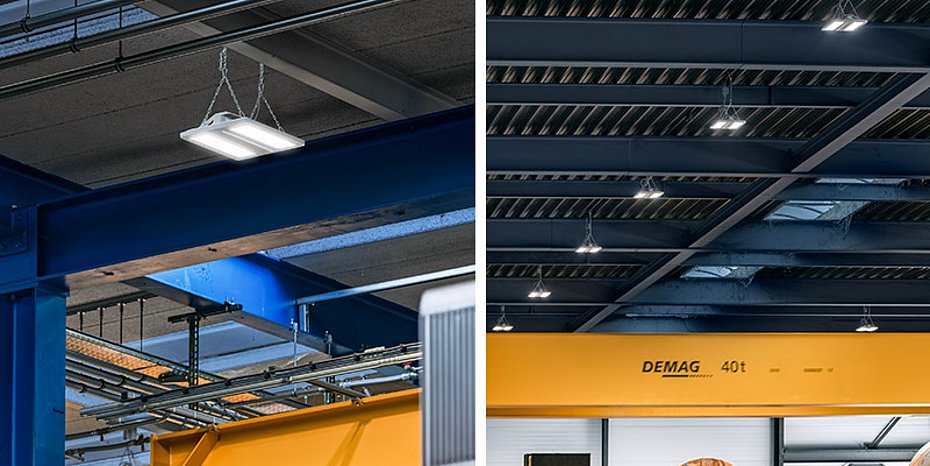

The Craft II plus LED high-bay luminaire from the portfolio of Austrian lighting expert Zumtobel is used where it gets dusty and hot, for example at Forming AG in Möhlin, in the Swiss canton of Aargau. In high industrial halls, the specialists produce cold-rolled profiles as well as slit strip made of metal for a wide variety of applications and industries. A whiff of oil and metal dust is in the air. Despite the most difficult environmental conditions: Precisely formed profiles - Swiss made - need precise illumination.

Swiss industrial quality meets Austrian lighting know-how

For the refurbishment of two large assembly halls, Forming AG wanted to replace an old stock of 400 watt sodium vapour luminaires with a robust but also future-proof lighting solution. In cooperation with Zumtobel, a lighting system was created that reduces energy consumption by up to 50 percent. And also emits a much higher light output: "Craft II plus luminaires have a luminous efficacy of 134 lm/W. The old sodium vapor luminaires delivered only 65 lm/W," says Philipp Büchler, project manager at Zumtobel Switzerland. The best conditions for production under very high industrial ceilings.

Resistant to oil, metal dust and temperature fluctuations

Before more than 300 Craft II plus high-bay luminaires went into operation, the project partners first analyzed the most important framework data: "Forming AG produces in two-shift operation. This means that our lighting solution must allow long switch-on times," recalls Philipp Büchler. In addition, the luminaires had to be resistant to an oily atmosphere as well as pronounced temperature fluctuations. Philipp Büchler: "The production halls of Forming AG are partly open - as a result, the operating temperature can drop sharply in winter." No problem for Craft II plus: It is suitable for ambient temperatures from -40° to +70° Celsius.

Protective shield from a single mold

To ensure that neither water nor chemicals penetrate the luminaire from above, Craft II plus by Zumtobel features a so-called Craft Protection Shield (CPS). The high-quality aluminum housing is made of a single casting and forms a kind of protective shield for demanding industrial environments. It completely covers sensitive components such as sensors, emergency and IoT technology. The housing is also particularly conductive and reliably dissipates heat.

Cools and cleans itself

"The intelligent design of the high-bay luminaire ensures that the Zumtobel Craft II plus can cool itself and clean itself of the smallest metal dusts," says Philipp Büchler. To achieve this, the industrial luminaire uses two principles from physics known as the Venturi effect and the Coandă effect. In an intelligent interplay of air pressure, air speed and air temperature, LED drivers and LED boards are cooled and everyday dust is removed from the luminaire surface. The great robustness of the Craft II plus also has a positive effect on possible maintenance times, according to Philipp Büchler: "The service effort is significantly reduced. Production can run without interruption."

Sustainability that pays off

In order to take environmental aspects into account when refurbishing the two large assembly halls and to significantly reduce CO2 consumption in production, Forming AG engaged an external energy consultant. With Craft II plus, Zumtobel is paying towards the ambitious sustainability goals: "Simply by converting old sodium vapour luminaires to modern LED technology, Forming AG can realize energy savings of 30 to 50 percent," says Philipp Büchler. This is not only a plus in the company's balance sheet, but also gives the profile specialists access to subsidies. Zumtobel also offers so-called EPDs: Environmental Product Declarations (EPDs) document environmental impacts of a lighting tool over its entire life cycle. This makes it possible to transparently track the contribution that the lighting makes to the company's climate targets.

Light in Zumtobel quality

In addition to pioneering technologies, the Zumtobel Group's lighting expertise also comes into play in Craft II plus. The optical engineers have recreated a natural phenomenon called TIR - Total Internal Reflection. Transparent, laser-structured lenses with micrometrically small, diagonal dome structures reflect all the light like a mirror. As a result, the high-bay luminaire distributes the light beams optimally in the room - for the best visibility during challenging activities.

Perfect light does not have to be an effort

The example of Forming AG shows: Even in challenging industrial environments, the Craft II plus succeeds in combining excellent lighting quality, maximum robustness and energy efficiency. Philipp Büchler puts it this way: "Forming AG's perfect profile is created when force is applied. The perfect lighting solution by Zumtobel, on the other hand, does not have to be an effort." (OM-3/23)

Contact

Zumtobel Lighting GmbH

Schweizer Strasse 30

6850 Dornbirn (Austria)

Phone: +43 (5572) 390-0

E-mail: info@zumtobel.info

www.zumtobel.com

About Zumtobel

Zumtobel is a company of the Zumtobel Group and the leading international supplier of integral lighting solutions for professional indoor and outdoor building lighting. Zumtobel has been developing innovative and individual lighting solutions for 70 years. As an innovation leader, Zumtobel offers a comprehensive range of high-quality luminaires and lighting control systems for various application areas in professional building lighting.