Wind energy: Accelerate tower production with fast-drying paint system

The demand for wind energy is booming. In order to meet market requirements, a construction company wants to increase throughput in tower production. This can now be achieved with a particularly fast-drying polyurea coating system.

The Transrapid line in Shanghai, subway stations in Amsterdam or Berlin Central Station - the Max Bögl Group has already made all of these and many other major projects a reality. The company from Sengenthal in the Upper Palatinate was founded in 1929 as a bricklaying business and is still firmly in the hands of the third generation of the family.

Wind energy is a relatively new mainstay at Max Bögl: the Upper Palatinate company supplies towers made from three-meter-high concrete rings in a modular system and a metal tip. The special feature is that each ring consists of three individual parts, for which the construction company holds a patent. This makes the components much easier to move - a standard truck trailer is sufficient for their transportation. Around 30 concrete rings are stacked on top of each other and braced before the metal tip - a real heavyweight weighing around 60 tons - is placed on top. For this reason, various rings are made of a special concrete that can withstand the loads in the long term thanks to its steel reinforcement.

Paint system for fresh concrete

Since March 2022, the family business has been using a new paint system for the concrete elements. It comes from FreiLacke and is a very fast-drying polyurea-based material. "We have a wealth of experience in the wind energy sector - and not just when it comes to towers," explains Andreas Löffler, who is responsible for international business development at FreiLacke.

At the Sengenthal plant, the concrete components are demolded after curing and transported directly to the paint shop. "Because there is still a certain amount of residual moisture in the concrete, special paint systems are required. In addition, the parts could still be warm after demolding due to the reaction heat of the concrete," explains Bögl Production Manager Holger Roth. The polyurea-based polyaspartic paint systems from FreiLacke meet precisely these requirements and enable immediate painting.

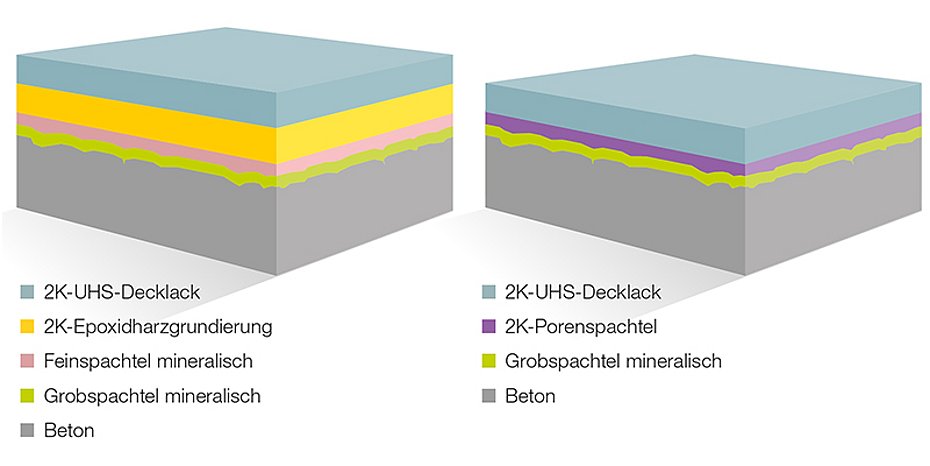

The concrete rings are transported in the paint store at Max Bögl on platforms on an automatic conveyor system. Here, their concrete surfaces are first prepared and smoothed; the cycle time is currently just under an hour. The aim here is to close any pores and cavities for the best possible paint adhesion. The FreoWind filler in light gray is one of the products used here. The next step is the top coat, which is applied using the airless method as standard. The paint has already dried after the cycle and is therefore ready for all further steps.

Double application against stress cracks

Painting is primarily used to improve the appearance of the components: The layer of paint also gives them high mechanical strength and dirt-resistant properties. Two further workstations in the hall are reserved for the finishing work on the heavyweights; the components are then stored outside once they have been painted. From now on, they are permanently exposed to wind and weather - and optimally protected.

By switching to the FreiLacke system, the construction company primarily wants to increase the throughput of its concrete components, as the demand for new wind turbines is high - the war in Ukraine has acted as an international booster, says Andreas Löffler. The construction company is therefore planning a significant increase in production figures from summer 2022.

Rheological settings for easy processing

As Andreas Löffler reports, the changeover to the new paint system went quite smoothly; he was on site in Sengenthal together with an application engineer. The only thing that required meticulous pre-planning was the paint supply via a ring main. "The workers actually really like working with the system," says Löffler, "as the primer filler is particularly easy to apply and fits in very well with the existing application technology - at the FreiLacke headquarters in Bräunlingen-Döggingen/Black Forest, our colleagues have worked on the rheological setting specifically for this purpose."

Incidentally, Max Bögl is now also active in wind energy itself: Bavaria's most powerful wind power plant with a Bögl tower went into operation in 2011 on the Winnberg in the district of Neumarkt. With a total height of 180 meters and a connected load of 3.4 megawatts, the plant produces more than a third of the municipality's electricity consumption. In addition, the specially founded Max Bögl Wind AG, together with turbine supplier GE Wind Energy, has held the record for the world's tallest wind turbine since 2017: the Upper Palatinate-based company supplied the towers for four wind turbines in Gaildorf / Baden-Württemberg with a hub height of 178 meters and a total height of 246.5 meters.

Contact

Emil Frei GmbH & Co. KG

Am Bahnhof 6

78199 Bräunlingen-Döggingen (Germany)

Phone +49 7707 151-0

info@freilacke.de

www.freilacke.de

About FreiLacke

FreiLacke has stood for innovative paints and coatings since 1926. The family-run company is now in its third generation and, with 600 employees at its site in Döggingen/Black Forest, develops customized solutions for customers in the fields of wheels, vehicle construction, mechanical and apparatus engineering, contract coating, rail vehicles, wind power, functional furniture, storage technology, construction and sanitary facilities.